PARIS — January 14, 2026 — In a context marked by persistent geopolitical tensions, increased regulatory pressure around eco-responsibility, and a radical transformation driven by AI—placing data and digitalization at the heart of strategies—the fashion industry approaches 2026 with the need to fundamentally rethink its models. This ongoing transformation requires brands to integrate their data, revisit business models through circular approaches, make production chains more flexible and closer to markets, adapt distribution strategies to growing complexity and fragmented networks, while aligning governance with strengthened standards of transparency and sustainability.

PARIS — January 14, 2026 — In a context marked by persistent geopolitical tensions, increased regulatory pressure around eco-responsibility, and a radical transformation driven by AI—placing data and digitalization at the heart of strategies—the fashion industry approaches 2026 with the need to fundamentally rethink its models. This ongoing transformation requires brands to integrate their data, revisit business models through circular approaches, make production chains more flexible and closer to markets, adapt distribution strategies to growing complexity and fragmented networks, while aligning governance with strengthened standards of transparency and sustainability.

Lectra, a leader in industrial intelligence solutions for the fashion industry, identifies five structural trends that will redefine strategic priorities for sector players in 2026—between adaptation, innovation, and new levers of competitiveness.

Five major fashion trends to watch in 2026:

- Digitalization and Industry 4.0 technologies: From option to necessity

Digitalization is no longer seen as optional but as a survival tool. This is evidenced by the growing recognition of the importance of data in the fashion value chain, accelerated by AI adoption—though uneven across regions and company sizes. AI now affects all fashion professions: from design to production, collaboration, traceability, and marketing. It operates at multiple levels: data research and collection to feed models, automated processing (categorization, classification), and content generation (text, image, marketing). These AI applications transform processes without replacing designers but redefine their role within digital-first ecosystem.

A major trend is Agentic Shopping, which is redefining the customer experience and visibility rules for brands and retailers. While traditional search engines remain dominant with SEO/SEA strategies, paid advertising has its limits (high costs, declining ROI). Gradually, these approaches may give way to GEO (Generative Engine Optimization), which entails making product data richer, contextualized, and accessible to AI agents. Structured, machine-readable content becomes a key competitive lever, putting data back at the heart of winning strategies. To thrive in these new digital environments, brands must enrich metadata and ensure traceability. Lack of digitalization means risking disappearance: data becomes a central competitive asset.

Facing these technological disruptions, companies seek to modernize processes, reduce geopolitical dependency, and build new competitive advantages based on technology and data.

- Supply chain reset: A global redistribution

Trade tensions and tariffs between the U.S. and China accelerate a trend that began a decade ago: diversification of production hubs. Brands—especially those based in the U.S. or distributing in the American market—aim to reduce reliance on China, which still holds over 20% of U.S. apparel import share (Source: OTEXA). Vietnam and Bangladesh emerge as strategic hubs, while India declines due to high U.S. tariffs. Cambodia and Indonesia have seen strong order growth but struggle to meet demand with current capacities.

This redistribution is complex: lack of established supplier relationships, significant investments, and uneven industrial capacities. Players who anticipated these shifts now have an edge, while European transparency requirements reinforce the need for digitalization, traceability, and automation. AI plays a key role in guiding this transition, optimizing processes, and boosting agility. These investments are no longer a competitive advantage but a prerequisite to serve certain markets.

- Price-value ratio: A trade-off redefining consumer choices

Price remains a decisive criterion but now goes hand in hand with perceived product value. The luxury slowdown illustrates this: after sharp price hikes, the sector failed to justify intrinsic value amid outsourcing scandals, lack of transparency, and quality issues. For Western brands, competing on ultra-fast fashion pricing is impossible—they play by different rules. The challenge is to strengthen perceived value through quality, transparency, and commitment rather than engaging in price wars.

This tension leads not to hybrid strategies but to a revamp of assortments and pricing policies. Mid-market and premium brands have adjusted their mix: more high-value products, fewer promotions. A winning strategy: according to McKinsey (State of Fashion), these brands generated the most value in 2025.

- Sustainability and regulatory compliance: A strategic imperative

Sustainability is no longer a strategic choice but a mandatory requirement for all fashion players. Europe—like France, a pioneer in these matters—is set to impose strict standards on traceability and environmental labeling, with measures such as the eco-score and Digital Product Passport currently under discussion at the EU level. These norms aim to inform consumers and ensure transparency, but implementation remains complex: divergent criteria between French and European approaches and a “default” rating system for brands unable to provide full data. This mechanism puts ultra-fast fashion giants, who deliberately withhold data, on the same level as small virtuous brands limited by operational means. For example, the average price of an ultra-fast fashion item is about €9—three times less than mid-market (source: IFM). This distortion heightens the urgency to reaffirm value beyond price.

For subcontractors, compliance becomes a lever of attractiveness: in Bangladesh, for instance, the BGMEA textile association invests in traceability systems to remain competitive. Without reliable data, CSR efforts remain invisible: technology becomes essential to reconcile sustainability and performance. In a context of rising regulatory pressure, brands also explore how new technologies—especially AI—can become strategic assets for efficiency, transparency, and competitiveness. An innovative solution like TextileGenesis verifies material authenticity and sustainability using AI-managed token attribution.

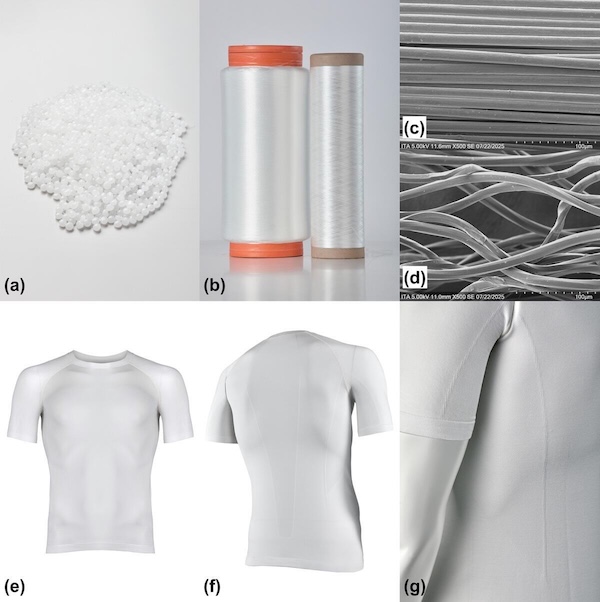

- Second-hand fashion and new business models: The silent revolution

The second-hand market continues to grow and is expected to expand two to three times faster than the new market between 2025 and 2027 (source: State of Fashion 2026), driven by the search for better price-value ratios amid weakened purchasing power—particularly affecting “non-essential” categories like apparel. Platforms such as Vinted in Europe or The RealReal in the U.S. illustrate this trend, while brands increasingly integrate resale into their models to extend product lifecycles. Circular models like upcycling and recycling face challenges in material quality and traceability, hindering reprocessing. The fashion industry highlights the need for investment in technology and textile innovation to scale these models.

In the short term, the best solution remains producing better, avoiding overstocks, and optimizing distribution with adjusted collections and a robust omnichannel strategy.

These five trends confirm the sector’s entry into a systemic transformation phase where economic performance, risk management, and environmental responsibility are inseparable—a logic we can call “econogy,” combining economy and ecology to define new competitiveness standards. In 2026, brands investing in traceability, digitalization, and value chain optimization will stand out in a fragmented, demanding, and volatile global market.

Far from being a constraint, this shift represents an opportunity for players ready to adapt. The most-used word by fashion executives to describe the industry is no longer “uncertainty” but “challenging”: constant change is now the norm. While 45% anticipate worsening market conditions, 25% expect improvement in 2026 (source: State of Fashion 2026). In a world where uncertainty is permanent, companies should not wait to modernize operations, review processes, and build resilient business models capable of absorbing successive shocks. Those already moving turn complexity into a lever to build more resilient, sustainable businesses aligned with consumers seeking meaning and value—and better differentiated amid intensified global competition.

Posted: January 19, 2026

Source: Lectra