Panda Biotech’s President Dixie Carter discusses the company’s part in developing the U.S. hemp ecosystem — growing, processing and building partnerships with an eye on sustainability.

TW Special Report

It was clear early on in this interview that Panda Biotech’s story was about much more than just building a new hemp gin in Wichita Falls.

Panda Biotech’s President Dixie Carter captured the scope of Panda’s approach saying: “By combining regenerative agriculture with clean, efficient technology, we’ve created a model that aligns with the future of sustainable textile manufacturing: local, traceable and circular. The result is not only a lower-impact natural fiber alternative but also a blueprint for how innovation and sustainability can coexist at industrial scale — right here in America.”

And that is the heart of the story, something that’s much bigger than a plant or a company, but is a new industry from farm field through final products.

Carter recently sat down with Textile World to share her take on creating a new industrial hemp ecosystem.

TW: How did the idea of developing a scalable industrial hemp ecosystem take shape?

Carter: After decades of building clean energy projects, Panda saw industrial hemp as the next frontier in sustainability. The same principles that powered Panda Energy’s success — innovation, efficiency and environmental responsibility — now drive Panda Biotech as we build a fully integrated, zero-waste hemp fiber ecosystem here in America.

TW: How did your previous executive experiences assist you in your role at Panda?

Carter: Throughout my career, I’ve led collaborations with some of the world’s most recognized brands across entertainment, fashion, merchandising and industry. My expertise lies in building brands that connect deeply with people — through storytelling, marketing strategy, global partner-ships and capital development. At Panda Biotech, those same principles apply. We’re building a movement as much as a business — reintroducing American-grown, American-processed hemp fiber to the global textile market.

TW: How does Chairman Bob Carter’s “no excuses” leadership style, influence your management approach?

Carter: Bob’s no excuses leadership sets a tone of accountability and action. He believes every challenge has a solution —and that mindset has become the heartbeat of Panda Biotech’s culture. This mindset reinforces that there’s always a way forward, but it requires discipline, collaboration, and an unwillingness to let obstacles become excuses.

TW: What milestones has Panda Biotech achieved in the development of American Hemp?

Carter: Panda Biotech’s momentum has been built through a series of strategic milestones from purchasing the building, sourcing the right equipment and building out our facility, raising capital, finding the right seed to grow in our region, partnering with farmers and then working with them to have a successful harvest, commissioning the equipment, working with mills to dial in the right fiber for mass production, and so much more. Panda reinforced each milestone to build credibility, capacity, confidence, and a foundation for a truly American hemp supply chain with global reach and long-term sustainability.

TW: How has Panda’s sustainability focus impacted your choices in designing the Panda hemp gin?

Carter: Sustainability is not a single pillar of Panda’s business — it’s the foundation of everything we do. From the outset, our goal was to demonstrate that industrial hemp can be scaled in a manner that protects both people and the planet. We built the Panda Hemp Gin in Wichita Falls, Texas, to reflect that commitment in every detail.

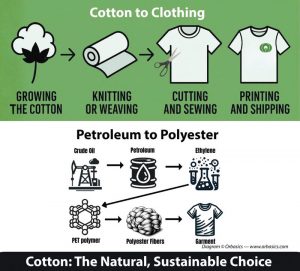

Panda’s facility is the most advanced, large-scale industrial hemp processing operation in the Western Hemisphere — engineered for zero waste. Our mechanical cottonization process transforms U.S.-grown hemp into a fine, textile-grade fiber, eliminating the use of water or chemicals typically associated with degumming or scouring. Every part of the plant is utilized across multiple value streams.

TW: Building any facility is challenging enough, but what about making choices — like choosing to pursue mechanical cottonization or using renewable energy?

Carter: From the outset, our goal was to develop a model for large-scale natural fiber processing that could be both environmentally clean and commercially viable — not a pilot project, but a proof of concept for U.S. manufacturing. Our products are OEKO-TEX® STANDARD 100 certified, USDA BioPreferred®, and meet the highest standards for clean fiber production.

Choosing mechanical cottonization was a pivotal decision. We considered bringing degumming in-house, but the water and chemical requirements ran counter to our sustainability goals. Instead, Panda created a textile-grade fiber using only mechanical cottonization, which had notably fewer short fibers and bundles, and was finer, softer, and longer — similar to degummed and scoured fiber. While this took us longer to achieve, we now have the best and best-priced, mechanically cottonized, textile-grade fiber in the world, at half the price of degummed hemp fiber. This process enables hemp to integrate seamlessly into existing cotton spinning systems, which is crucial for broad textile adoption.

TW: The Wichita Gin is a substantial development. How did you get your arms around the project, and what was the key to managing a team to execute the considerable plan?

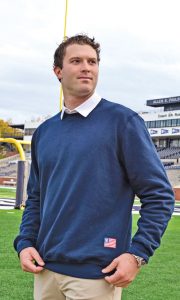

Carter: From the outset, we knew that building the Panda Hemp Gin would be unlike any industrial project ever undertaken in this sector— both in scale and technical complexity. We traveled the world examining equipment and hemp facilities. We assembled an exceptional team of experts in mechanical design, automation, and industrial construction, many with decades of experience in large-scale facilities for the cotton, energy, and ag-processing industries. The state-of-the-art processing line, if measured end-on-end, spans 700 yards — or 7 football fields — with three miles of overhead pneumatic ducting, custom-engineered decortication systems, and a continuous flow design that has never been implemented for hemp at this capacity.

A project of this size demands clarity, collaboration, and commitment. We aligned every engineer and operator around one vision — to build some-thing historic — and that shared purpose made the impossible achievable.

TW: What is your personal connection to Wichita Falls and Seymour, Texas?

Carter: Our family had a ranch in Seymour, Texas, for more than 20 years, so we spent time in the closest big city, Wichita Falls. When we were searching for a building for our first hemp gin, our focus was on very large industrial buildings with high ceilings. When we found a 500,000-square-foot former GM facility on a 97-acre campus that also happened to be in a city where our family had history, we knew we had the perfect place.

TW: Panda’s Gin is just part of the story. Can you address Panda’s concentration on the hemp ecosystem — from the farm to merchantable product like the “Pay-to-Grow” program?

Carter: The Panda Hemp Gin is the center-piece of a much larger vision — building a truly scalable and sustainable hemp fiber ecosystem here in the United States. From the outset, we recognized that processing capacity alone wouldn’t be sufficient. To make hemp viable at scale, you need to connect every link in the chain, including regenerative farming, world-class mills, and finished consumer products.

That’s why we’ve invested heavily in programs that support farmers and mitigate risk for participation. Our Pay-to-Grow program was a cornerstone of that effort for us at the beginning. It ensured growers were compensated for their work while we provided them with genetically proven and consistent seed, agronomic guidance, and a guaranteed market for their harvested stalks. It was a true partnership model that fostered trust and created economic opportunities for American producers.

Beyond the farm, we’ve built relationships with yarn and textile mills, nonwoven manufacturers, and brands that are eager to integrate our U.S.-grown hemp fiber into their supply chains. The result is a fully domestic, traceable, and circular model — from seed to fiber to finished product — that helps revitalize rural economies while advancing the next generation of sustainable materials.

TW: What is your vision for the future of industrial hemp?

Carter: Hemp is not a fashion trend. It is the future of textiles and fashion. Scientifically proven to absorb more carbon dioxide per acre than any forestry or commercial crop, industrial hemp is the most transformative natural fiber opportunity of our time. It’s renewable, traceable, and circular by design— and it can be grown and processed at scale right here in the United States. Our vision is a global textile industry where hemp stands alongside cotton and synthetic fibers as a core, mainstream fiber — delivering performance, sustainability, and resilience. Early demand is coming from brands and mills that want to decarbonize their supply chains, starting with denim and knits. The long-term potential of hemp touches every sector of textiles.

TW: Are there any significant challenges in developing a vibrant industrial hemp future?

Carter: Any time a new natural fiber enters the global supply chain, the biggest challenge is consistency — mills and brands need to trust that the fiber will perform the same way, every time. Our focus has been on derisking the transition by producing cottonized hemp fiber that integrates seamlessly into existing spinning systems. We’ve partnered closely with leading mills to conduct extensive spinning trials, optimize blending ratios, and verify quality at scale. By delivering both performance data and a reliable domestic supply chain, we’re helping brands adopt hemp with confidence.

TW: Where does Panda Biotech go from here?

Carter: With the Panda Hemp Gin now fully operational, our focus turns to expanding the ecosystem — deepening partnerships with mills, manufacturers, and brands who are ready to integrate U.S.-grown, low-impact hemp fiber into their supply chains.

We’re also advancing our bioproducts portfolio, using every part of the plant to create renewable solutions across textiles, nonwovens, and industrial applications. At the same time, we’re working to strengthen our grower network, ensuring that regenerative hemp cultivation continues to create opportunity for U.S. farmers.

In many ways, this is just the beginning. The infrastructure is built, the partnerships are forming, and the demand for sustainable, traceable materials has never been stronger.

The editors of TW appreciate the opportunity to sit down with Panda Biotech’s President Dixie Carter. Her vision is both deep and wide with a bright future for American hemp. As Carter states, “Our mission now is to scale what we’ve proven — to show that sustainability can drive both performance and profitability, and that American innovation can once again lead the world in textile and materials manufacturing.”

2025 Quarterly Issue IV