NEW YORK, NY — July 2, 2024 — Gordon Boggis, CEO of Carnegie, a leader in sustainable textiles and acoustical management solutions for the commercial industry, has joined Fast Company’s Impact Council. Carnegie’s Outdoor Biobased Xorel, the world’s first and only plant-based, commercial-grade indoor/outdoor textile, was also honored as a Fast Company Innovation by Design honoree, recognized in the “Bio Design” category for products that use organic matter or are directly inspired by nature.

NEW YORK, NY — July 2, 2024 — Gordon Boggis, CEO of Carnegie, a leader in sustainable textiles and acoustical management solutions for the commercial industry, has joined Fast Company’s Impact Council. Carnegie’s Outdoor Biobased Xorel, the world’s first and only plant-based, commercial-grade indoor/outdoor textile, was also honored as a Fast Company Innovation by Design honoree, recognized in the “Bio Design” category for products that use organic matter or are directly inspired by nature.

The Fast Company Impact Council is a collective of the most innovative leaders in business. Members meet several times a year for roundtable discussions focused on finding innovative solutions to today’s most pressing and complex business problems . These gatherings focus on the role companies and council members can play in shaping the future by steering their industries towards more efficient, equitable, and sustainable operations. Fast Company amplifies members’ impact by publishing their thought leadership and tapping their expertise to inform the publication’s coverage of innovation across the business world.

“I am honored to join Fast Company’s Impact Council, a unique forum that brings together visionary leaders dedicated to addressing some of the world’s most critical challenges through innovation and collaboration,” said Boggis. “At Carnegie, we believe in the power of design to make a positive impact on people and the planet. Being part of this esteemed council is a testament to our commitment to sustainability and innovation. I look forward to contributing to the conversations and initiatives that will help shape a more sustainable future for all.”

As CEO of Carnegie, Boggis has been instrumental in continuing the brand’s 70+-year commitment to responsible innovation. Carnegie continues to be the first and only 100% PVC-free textile and acoustic solutions company in the industry. During Boggis’s tenure, the company has maintained its status as a certified B Corporation (B Corp), a designation that requires the highest environmental standards of verified environmental performance, accountability, and transparency. Carnegie has been B Corp-certified since 2014 and was recertified in 2022, a process that requires a rigorous and holistic evaluation of the company’s achievements in the environmental and social spaces.

Before joining Carnegie in April 2021, Boggis led companies across various industries, focusing strongly on textiles, innovative materials, health and wellness, and purpose-driven and environmentally sustainable businesses. He’s passionate about harnessing the talents of companies to be a force for good and deliver positive environmental change.

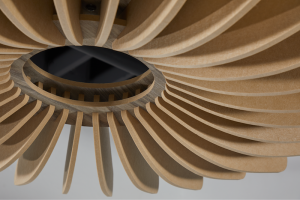

In alignment with Boggis’s vision for the company, Carnegie launched Outdoor Biobased Xorel in December 2022, the world’s first plant-based, fossil fuel-free, commercial-grade outdoor textile. Rising above any unsubstantiated greenwashing claims, Outdoor Biobased Xorel is the first and only indoor/outdoor textile to achieve Cradle to Cradle Gold and Living Product Challenge certifications. Sourced from rapidly renewable sugarcane, it has a significantly lower environmental footprint than any fossil fuel-derived product while maintaining Xorel’s legendary performance qualities. For each ton of sugarcane used to produce Outdoor Biobased Xorel, 2.5 tons of carbon is captured and sequestered, making it a climate-positive product.

“The Impact Council represents the ideal version of Fast Company’s readers,” says editor-in-chief Brendan Vaughan. “These are some of the more creative, mission-driven people in business, with some of the most original ideas about how to solve big problems and build the future. It is our great pleasure and privilege to bring this community together.”

For more information about Carnegie, visit www.carnegiefabrics.com.

Posted: July 5, 2024

Source: Carnegie / Fast Company