![]() MILAN — November 24, 2025 — Ermenegildo Zegna N.V. — together with its consolidated subsidiary, the Ermenegildo Zegna Group — today announced a new leadership structure for the group and ZEGNA brand, effective January 1, 2026. The changes follow a succession planning process carried out thoroughly by the Board of Directors.

MILAN — November 24, 2025 — Ermenegildo Zegna N.V. — together with its consolidated subsidiary, the Ermenegildo Zegna Group — today announced a new leadership structure for the group and ZEGNA brand, effective January 1, 2026. The changes follow a succession planning process carried out thoroughly by the Board of Directors.

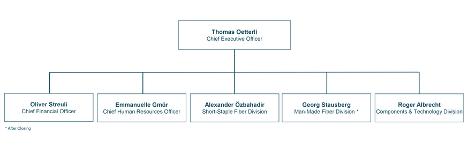

Ermenegildo “Gildo” Zegna, currently group chairman and CEO, will assume the role of group executive chairman. In this capacity, he will focus on safeguarding the legacy and integrity of the group’s three brands — ZEGNA, Thom Browne, and TOM FORD FASHION — while continuing to drive long-term value creation. He will also retain oversight of the group’s Textile Division, the group General Counsel’s office (including Internal Audit), and the External Relations department, which encompasses Sustainability, Investor Relations, and Corporate Communications.

Gianluca Tagliabue, currently group CFO and COO, will assume the role of group CEO subject to shareholders’ approval1. Working in close partnership with the group executive chairman, Tagliabue will be responsible for shaping and executing the group’s long-term strategy, driving business performance across all brands, and further strengthening the integration of the group’s corporate functions. He will also oversee manufacturing operations. The CEOs of the group’s brands will report to him. Gian Franco Santhià, currently group control & chief accounting officer, will be appointed as group CFO, reporting to the group CEO.

Edoardo and Angelo Zegna, members of the fourth generation of the Zegna family, will be appointed co-CEOs of the ZEGNA brand. They will succeed Gildo Zegna, who has held this role for more than 20 years. Edoardo Zegna, currently chief marketing and digital officer of ZEGNA as well as group chief sustainability officer, will lead all aspects of brand strategy, from brand image to marketing, and, together with ZEGNA’s Artistic Director Alessandro Sartori, design matters, including store design. Angelo Zegna, currently CEO of ZEGNA’s EMEA region and Global Client Strategy director, will oversee product development, merchandising, and commercial strategy, driving performance across markets and channels.

Gildo Zegna, chairman and CEO of the Ermenegildo Zegna Group, commented: “I am proud and excited about today’s announcement. One of the most important responsibilities of a leader is to think ahead — to prepare for the future and empower the next generation of leadership. This belief has always been deeply rooted in our family values and is a key force behind today’s announcement.

Together with the Board, I have asked Gianluca Tagliabue to assume the role of Group CEO. Over the past decade, Gianluca has been a cornerstone of our Group, leading the company through key transformations. The Ermenegildo Zegna Group is a custodian of authenticity. Gianluca embodies this philosophy and will support the CEOs of our brands in pursuing the Group’s mission as a trusted and forward-looking guide.

Edoardo and Angelo’s complementary strengths and clear vision will make them a highly effective team to lead ZEGNA brand. They continue the family legacy and have demonstrated their business leadership over the past years. Together, they will not only carry forward the brand’s timeless heritage, but strengthen it further.

As executive chairman, I will stand alongside our new leadership team and all our colleagues — a curious and passionate custodian of our brands’ vision and values, as I have always been. I will also continue to oversee the Group’s textile platform — where it all began. I am looking forward to shaping our Group’s next chapter with this new leadership team.”

Posted: November 25, 2025

Source: Ermenegildo Zegna Group