“C

ustomization and smaller lot sizes have become increasingly relevant for US producers,”

said Paul Jankovic, president, The Gessner Co. The Charlton, Mass.-based company specializes in

sublimation heat-transfer printing and mechanical finishing. “The smaller, specialized, quick-turn,

full-package providers are becoming more important to our US customer base,” Jankovic added.

Antonio Staffoni, managing director, Sperotto Rimar S.r.l., Italy, echoed Jankovic’s

sentiments. He said the most active area for Sperotto Rimar has been the Far East, especially

China. “The US has also increased its buying from us, although the volume is much smaller.”

Process automation and control innovations have fine-tuned the dyeing, printing and

finishing production process in recent years – lowering costs and increasing quality while

facilitating increased customer demands.

Benninger’s BenColour continuous dyeing equipment for woven and knitted fabrics is suitable

Benninger’s BenColour continuous dyeing equipment for woven and knitted fabrics is suitable

for a variety of dyeing needs.

Maximizing Control

Charlotte-based Adaptive Control sees the United States as a still viable and lucrative

market for its PC machine control systems for all types of dyeing and finishing machinery and other

auxiliary equipment. The company uses cost-cutting techniques to supply its customers with

inexpensive solutions and technology.

“The focus is on manufacturing at the lowest cost in a timely manner, without defects the

first time,” said Tony Webber, sales director. “Innovation is the key to a successful company.”

The company provides machine control systems that are open and non-proprietary, and also

Web-based for easy global communication.

“PC control and Web-based technology has allowed us to monitor machinery in ways that we

thought were not possible,” said Webber. “We have recently completed putting our Adaptive Control

Plant Explorer Operation Host onto the latest Microsoft platform. This will give Adaptive Control

the ability to extend our systems to the very latest technology available.”

This type of control technology allows a plant operator to walk the production floor with a

hand-held, touch-screen PC device that monitors performance, machine status, and allows user

intervention if necessary.

Automation and control come together in the Powderflo 2000 automatic bulk powder dispensing

system from Adaptive Control UK, the firm’s sister company in England. The Powderflo is a PC-based

control system with network connection that monitors powder flow by means of level detection at the

base of the bin, and continuously monitors bin and powder weight, reducing the need for operator

handling.

Scholl-Then AG, Switzerland, supplies top-of-the-line process controls, in addition to color

and chemical dispensing systems, for efficient and economical dyehouse operation, according to

Roland Adrion, marketing manager. The company manufactures advanced dyeing equipment, such as the

Airflow and Rapidstar piece-dyeing machines, and yarn- and beam-dyeing machines. Adrion mentioned

that in recent years, Scholl-Then has supplied dyeing machines with much higher capacities –

yarn-dyeing machine capacity now goes up to 2,300 kilograms (kg) per batch, and requests for

piece-dyeing machines with capacities of 900 kg or more are common.

H.T.P. Unitex S.p.A., Italy, is active in pretreatment, dyeing and printing of woven and

knitted fabrics in rope and open-width form. According to Sandro Telasi, area sales manager, Unitex

is seeing an increase in market demand for fully automatic control systems, which minimize human

error and labor costs, maximize process reliability and repeatability, and ensure the high

flexibility necessary for today’s smaller lot sizes.

MCS Dyeing & Finishing Machinery, Italy, has incorporated full automation into its

latest offering, the Superdome Carpet Flow rope-dyeing machine. Suitable for carpet fibers

including nylon and multi-dye level nylon, polyester, and wool, the Superdome offers energy savings

of up to 60 percent and a 40-percent reduction in chemical product consumption, according to MCS.

Being fully automatic, the Superdome also ensures maximum performance, with perfect evenness and

repeatability, according to the company.

ColorService S.r.l., an Italian producer of automatic dye kitchens, offers the Superlab,

which allows operators to run the same dyeing procedure in the lab as on the production floor,

eliminating the need to take samples in between. Operators end up with not only a physical sample

at the end of the process, but also information to run the exact same procedure on the production

floor.

With Superlab, dye bath preparation is automatic. Superlab software monitors conditions of

the dyeing process, such as temperature control and impregnation. The machine then squeezes the

fabric to obtain the desired pick-up value, while at the same time controlling the fabric’s weight

until the desired result is achieved. The sample obtained from the process then is placed into the

appropriate conditioning area for the necessary amount of time. The Superlab then washes the

sample, dries it and ejects it.

Mageba Textilmaschinen Vertriebs GmbH, Germany, offers computer control on all of its

machines, enabling on-line servicing and maintenance programs via built-in modems from anywhere in

the world.

The Venus high-temperature jet-dyeing machine from England-based Sclavos offers Total

Interactive Control (T.I.C.) technology. With T.I.C. technology, the Venus continuously monitors

water and steam supplies. By comparing them to the supplies requested for the process by the

operator, the Venus adjusts to compensate for any water or steam supply shortcomings. According to

Sclavos, this technology eliminates human involvement, resulting in less error; ensures

repeatability from batch to batch; increases fabric quality; and increases profitability.

Klaus A. Heinrichs, vice president, marketing, A. Monforts Textilmaschinen, Germany, noted

today’s smaller lot sizes create a need for more process control, as well as shorter maintenance

response times. In response, Monfort’s Qualitex visualization and control system offers a large,

easy-to-read touch-screen monitor for process monitoring of the company’s programmable logic

controller (PLC)-operated complete stenter dyeing range.

Bill McAndrew, vice president of sales and marketing at Zima Corp., Spartanburg, has

recognized the demand for process control from customers of companies Zima represents, such as

Eduard Küsters Maschinenfabrik GmbH & Co. KG, Germany.

“Our customers are concentrating on shorter lot sizes, quick changeover capabilities,

minimizing waste and lowering inventories,” said McAndrew. “We have responded with equipment and

process controls to meet their needs, such as the patented Küsters Instacolor and Instachem

systems, which provide the dyer with systems to meet all of the above requirements in addition to

lowering labor costs.”

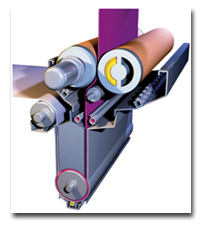

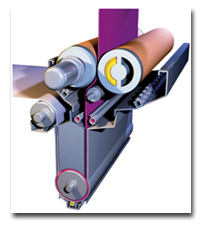

In addition, according to the company, Küsters’ “swimming roll” dye padder offers continuous

deflection control, which provides flexibility when combined with color and moisture management

systems; an on-line dosing system that allows optimum control of dye liquor composition; and

PLC-controlled quick cleaning with minimum water consumption.

Küsters dye padders offer optimum nip control through the use of two “swimming rolls” with

Küsters dye padders offer optimum nip control through the use of two “swimming rolls” with

continuous deflection control.

Finishing Trends

Benninger AG, Switzerland, has made control systems with touch screens an integral

information systems standard on all of its weaving preparation and textile finishing equipment.

Process control systems for all Benninger products include: control and drive system hardware

engineering; application-specific PLC control software programming; software programming of

HMI/SCADA systems; assembly and test of drive and control cabinets; and startup and commissioning.

Unitex developed its HWT washing unit in response to an increased industry need for

high-efficiency treatments and soft handling of trendy fabrics. The combination of effective

washing after pretreatment with dyeing and printing while applying low tension to the fabric is an

important factor in Unitex’s product line. “This allows much better performance than in the past

… and provides benefits such as saving water, higher production speeds and better final fabric

quality,” Telasi said.

Touch-screen control is also found on Glenro Inc.’s drying machines. The Paterson,

N.J.-based company offers predrying and drying equipment, including infrared and hot-air dryers.

Glenro also offers thermal oxidizers for control of volatile organic compounds (VOCs), in which

heat is recovered from the oxidation of VOCs and then used to heat make-up air for the dryer.

The integrated system, one that serves a fabric from pretreatment to finish, is one trend

worth noting, saving a company time and money. Santex AG, Switzerland, offers fully-integrated

systems for finishing of knitted open-width fabric.

Turnkey systems also are currently in demand. “It seems that manufacturers have less

engineering in-house and therefore need the vendor to provide engineering services,” said Jim

Alimena, vice president of marketing, Glenro. “That’s one of the reasons Glenro has an applications

lab in which we can test a customer’s product before they buy [the machinery]. We often help

customers develop applications and suggest the best way to apply heat to make products.”

Thies GmbH & Co. KG, Germany, manufacturer of yarn-dyeing and drying machines, and

discontinuous fabric machines, offers its customers turnkey dyehouse plants. These turnkey

installations include dyehouse management systems; dosing equipment for chemicals, dyes and solids;

and the latest dyeing machine technology to ensure a maximum profit at the lowest possible

investment.

Along these lines, software and hardware from a single source is more in demand. Obtaining

technology, machines and equipment from one manufacturer reduces time and money spent on

maintenance.

Dyeing fabric without previous preparation, again saving the manufacturer time and money, is

one trend in technology offered by Argelich, Termes Y Cia S.A., Spain, manufacturer of dyeing

equipment for industrial textile dyehouses. The company has developed Rapidstretch for the

treatment of fabrics in rope form, such as bengaline, that are highly susceptible to shrinkage and

other process defects.

Short liquor dyeing – dyeing using a lower liquor ratio – is according to Thies, a big trend

in purchased dyeing technology, resulting in less consumption of both dye and water, which equates

to less harmful environmental impact and initial outlay.

Touch-screen PC devices from Adaptive Control monitor performance and machine status, and

Touch-screen PC devices from Adaptive Control monitor performance and machine status, and

allow user intervention if necessary.

Technical Advantages

According to Hans-Peter Stang, managing director, Mageba, companies like Mageba that

specialize in dyeing and finishing of narrow fabrics can take the lead in the field of elastics

with dual-end high-production equipment that incorporates polyester-dyeing facilities for elastic

tapes, heavy-duty beltings and ribbon. Mageba currently uses Corona/Plasma technology in its

continuous dye ranges.

As almost any company would agree, reliable customer service is in fact a technical

advantage that always works for both customer and company.

Glenro has spent 43 years in the process heating industry and offers a variety of

heat-transfer technologies including infrared, convection and conduction. Alimena believes it is

the company’s eagerness to work with its customers that ensures repeat business.

“We see customers coming to us for process heating solutions to their application needs, not

just for a piece of equipment,” he said. Alimena cites the company’s experience, the variety of its

heat-transfer technologies and its applications lab as important components of Glenro’s customer

service operation.

According to Stephan Kehry, sales manager, Benninger, supplier responsibility to the

customer continues to be a must. It is vital for a company to gain as much input from its customers

as it can to keep abreast of industry demand.

Thies’ soft-TRD DS XL is the latest generation hydraulic overflow dyeing machine, which

offers low energy consumption.

Looking To The Future

Custom solutions that improve productivity and quality are necessary for sustained growth,

according to Manfred Aulbach, sales director, Fleissner GmbH & Co. KG, Germany, manufacturer of

continuous printing and dyeing lines, washing and drying lines, and heat-setting lines. Aulbach

added that safety practices must be increased, and second-quality product and waste material should

be reduced as well.

Just-in-time processing, enabling orders to be filled through a stable, accurate process in

which inventory isn’t left sitting on the plant floor, will be considered absolutely necessary for

accuracy in finishing, according to Uwe Sick, Santex sales manager.

Adaptive Control sees the future of dyeing, printing and finishing connected to wireless,

pocket PC technology. The company plans soon to introduce a 6-inch touch-screen version of its

current control technology.

According to Webber, “Graphics, production reports and machine monitoring will all be

available at the manager’s fingertips – outstanding control.”

“The future clearly lies in simple and easy-to-operate machines designed for quick color

changes,” said Stang. He believes it will be necessary to incorporate technologies such as plasma

treatments to reduce or eliminate the necessity of scouring, simplify formulations and reduce waste

water.

Ensuring Success

“As developing nations become more sophisticated market economies, there will be an

increased demand for higher quality garments with a rapid response to fashion demand for

color,” said Arthur C. Welman, technical consultant for Sclavos. “However, the location of

the dyeing industry will be determined by availability of good-quality water and water-treatment

facilities. The inevitability of water crises in the world will bring into sharper focus the need

to minimize water usage in the textile process.”

Reduced water consumption, ensured fabric quality, shorter process cycles, lower steam and

power consumption and higher return on investment keep dyers, printers and finishers searching for

the latest technological advancements. Keeping an eye on the updates is the only way to ensure

profitability.

March 2003

USTR

USTR