T

he beginning of the 21st century has been accompanied by ever more relentless cloth

quality specifications and requirements. One clear trend to meet these demands is the development

and implementation of suitable tools to secure process reliability and control in weaving.

In this scenario, however, it is essential that we first agree upon and understand the

aspects that determine cloth quality. Quality standards of woven fabrics have been as demanding in

recent years as the industry’s expectations with respect to productivity gains, cost-optimization

and shortened downtimes in the weaving process.

The main factors by which quality is measured are fabric properties and fabric defects. It

has become imperative to minimize faults deriving from the high-speed weaving process because

defects can usually be corrected only at considerable cost. Acceptable defect levels applied to the

majority of standard high-quality cotton fabrics throughout the world are quoted per 100 meters of

first-class fabric.

Whereas 20 years ago the tolerance was 15 non-repairable faults, the figure today is only

five. This trend will continue in the future and probably will be reduced to three permissible

faults in most instances. During the same time span, the share of seconds was brought down from a

maximum of 3 percent to 0.5 percent. Target figures for seconds in cloth manufacturing are likely

to go down to 0.3 percent of production in years to come.

Switzerland-based Sultex Ltd.’s latest projectile weaving machine, the P7300, features many

mechatronics to control weaving functions.

Machine Downtime

Also associated with fabric quality is the necessity to drastically reduce machine downtime.

This becomes more critical in economical terms with increasing machine performance, as plant

efficiency will drop even if downtime and frequency of stops remain unchanged. Fabric manufacturers

have come to understand that normally only a few permissible defects are accepted per 100 meters of

woven fabric. This reduction was attainable, among other reasons, by drastically curbing weaving

machine stoppages.

In cotton weaving, for instance, increased machine performance has meant a reduction of

machine stops by some 50 percent over the past 20 years – as few as three to five overall stops per

100,000 picks on average now are achievable in cotton weaving on high-speed weaving machines. Even

in woolen and worsted weaving – where yarn quality aspects are even more relevant – overall stops

can be reduced significantly via optimization of the weaving process.

Looking more closely at the main causes for weaving machine stoppages, one can determine

that out of the three to five overall stops in cotton weaving achieved on average today, 20 percent

are related to problems in the filling, and 80 percent are due to deficiencies in the warp.

Generally speaking, of the main causes of warp stoppage, 20 to 30 percent emanate from yarn

defects; 30 to 40 percent are directly or indirectly related to warp and weaving preparation; and

30 to 40 percent can be attributed to influences of the weaving process itself.

Obviously, a clear split between these criteria can be established only by a proper stoppage

cause analysis of the weaving machine itself. It does, however, suggest that any measures aimed at

optimizing the overall process not only should be targeted towards the weaving machine but also

should include the weaving/technological environment.

It is quite remarkable that, despite the fact that weaving machine speeds of traditional

weft-insertion systems have more or less doubled over the past two decades, improvements in the

weaving process have ensured that the very stringent and steadily increasing quality requirements

can effectively be met. This seems to prove that neither the ongoing enhancement of fabric quality

nor increases of weaving machine speeds are suffering from a target conflict.

This progress has partly been attained through a number of quality- and

productivity-enhancing factors, such as overall improvement of yarn quality and development stages

achieved in warp and filling preparation techniques. Even more decisive, though, has been the

progress made in the technological and operational reliability of the weaving process. It is

increasingly clear that the high-speed weaving machine – with its process complexities in relation

to type of fiber, yarn characteristics, fabric styles and finishes – involves high-tech

engineering. It has to live up to the most stringent requirements in functional reliability and

adaptability.

Only by further reducing down-time and incidence of faults in the weaving process, and

thereby shifting the concentration from labor costs to capital costs, can the US weaving industry

be attracted to invest. Coming to terms with some of the physical constraints of the single-phase

weaving process means the full potential of technology must be tapped. The day will almost

certainly come when solutions are technologically possible but economically can no longer be

justified using present technology.

For a better understanding as to what weft insertion at today’s machine speeds means in

physical terms, single-phase weaving machines apply and control pick velocities exceeding 60 meters

per second (m/s) and acceleration rates of more than 20,000 meters per square second (m/s2) in a

few milliseconds. This means the filling travels through the shed at speeds of more than 200

kilometers per hour (km/h) on modern single-phase weaving machines, imposing incredible demands on

the design of mechanical movements on weaving machines. Moreover, it requires sophisticated

electronics that enable optimal control and regulation of the timing of motion sequences in the

weaving process.

Despite all the progress made in weaving technology, the main objective is to further

minimize interruptions in the weaving process and thus prevent non-repairable weaving faults, with

solutions that are technically practicable and economically advantageous.

Yarn Stresses

A major task in minimizing the stoppage rate and assuring quality is to optimize yarn

stresses, such as time-related tensions and/or elongations. Tensions occurring in the warp differ

fundamentally from those affecting the filling yarn. Optimizing (in the sense of optimum yarn

tension) means keeping yarn tensions as low as possible, but also as appropriate as necessary,

because stoppages can be caused by both over-tensioning and under-tensioning the yarn.

Weaving systems are basically expected to tackle, for instance, worsted yarns and aramid

fibers equally as well at maximum speed. The processing performance of textile materials on weaving

systems is, however, also dependent on tenacity and elongation properties of yarns. To stress this

point, the natural worsted yarn typically would possess minimal strength but a high elongation,

while the reverse is actually the case for aramid fibers.

Sultex’s brand-new air-jet weaving machine, the L5400, features Internet

capability.

Weft Tension

The highest weft tensions occurring at pick insertion are caused by load peaks of extremely

short duration. Weft peak loads will always rise with increasing machine speeds or filling

insertion rates under equal mechanical machine conditions – no matter whether weft yarn is being

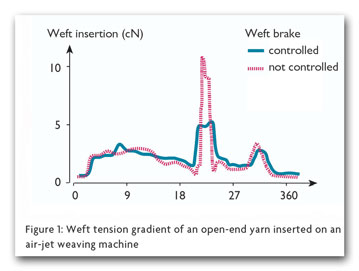

inserted on air-jet, rapier, projectile or any other single-phase weaving machine. Figure 1

illustrates the speed-related increase in load peaks in a cotton open-end yarn that, for purposes

of comparison, was inserted with and without controlled filling yarn braking on air-jet weaving

machines. One special feature of monitoring the weft-insertion path on air-jet weaving machines is

recording of the arrival time of the weft on the receiving side of the machine. This arrival time

changes according to variations in yarn characteristics.

The signal recorded controls the main- and relay-nozzle pressures, and the yarn speed is

then corrected to the target speed if necessary. Control measures aimed at reducing tension peaks

during filling insertion include electronic weft brakes that enable the weaver to set starting and

stopping times of the braking cycle as well as the braking force to be applied to every filling

channel used on a machine.

First tests with new and special sensing devices show that an automatic on-line optimization

of the filling-insertion cycle eventually will be within the realms of economical possibility.

Measuring heads or tension-sensing devices are integrated in the weaving machine and automatically

measure the tensile force acting upon filling yarns during insertion. With this control system,

electronic weft brakes can, in the future, be automatically adjusted to preset tensile forces.

Up to now, tensile forces could be determined only with the aid of expensive laboratory

measuring instruments. Utilizing appropriate process control systems – permitting on-line

monitoring of the filling tension during weaving – latest generations of high-performance weaving

machines will provide better conditions for minimizing yarn breakages. In the future, this on-line

force recorder also will be used to monitor the whole insertion phase of filling yarns, and

mispicks can then be positively detected.

Warp Tension

During the weaving process, the warp is subjected to both frictional stresses and cyclical

elongations that create tension in the yarn. Reliable information on the forces acting on the warp

ends can be obtained only from the warp tension trace.

The weaving process is still to be blamed for disturbances of the warp flow. Whereas 20

percent of warp breaks are yarn-related, 80 percent are linked to warp preparation and the weaving

process. Unfortunately, there is no constant tensile force acting on the warp sheet in terms of

time and place, neither across the weaving machine width nor in the warp direction, and also not

from warp end to warp end.

Along with reed beat-up, the factor having a particularly high influence on the extent of

yarn elongation and force pattern is the shed geometry, which can vary considerably according to

the weave and number and position of the frames, as well as the control of the backrest roller.

Optimization efforts for equalizing the flow of warp tensile forces are mainly attached to

system improvements in shed-forming dynamics of heddle frame movements, precision of cloth take-up

and warp let-off, and positive control of warp-tensioning devices.

Special warp-tension sensing devices that are incorporated in the weaving machine for

on-line tension recordings are available. In one machine configuration, this warp let-off control

motion is based on direct measurement of absolute thread tension. The sensing heads are arranged on

the deflection roller, thus safeguarding a considerably improved precision of the warp let-off

motion.

Influencing the warp-tension pattern even further by means of positively controlled

warp-tensioning devices allows for even better adjustments to process requirements. Controlled by

cam mechanism, positive warp-tensioning devices guarantee a warp control for reaching minimum

warp-stop levels.

A positive warp control is particularly helpful for:

• improving warp separation;

• reducing warp tension even further;

• minimizing load peaks for yarns with low tensile properties – thus

drastically improving the weaveability of single yarns in the warp;

• increasing weft density;

• directly controlling the position of the cloth fell; and

• controlling fabric structure as well as its appearance.

For further on-line warp control improvements, automatic adjustment mechanisms for the

backrest system are being studied.

Role Of Mechatronics And Electronics

Yarn stresses that are to be tamed for best weaveability and quality require a more

scientific approach towards process control in weaving. Mechatronics are clearly gaining importance

in this respect. The benefits of gear control by such means as servo motors are much

appreciated by weavers.

By electronically synchronizing the let-off with the take-up system, a dynamic cloth-fell

correction after a machine stop is feasible, and the intensely annoying start-mark problem will

become less of a topic in the future.

Improved process requirements in weaving derive not just from quality issues but also from

ever-increasing demands for ever-faster changeover times in plants. “Flexibility,” “quick response”

and “just-in-time” are no longer buzzwords – they are important aspects, particularly for American

weavers.

Flexibility in weaving means quick changing-over and fast-setting of weaving machines to

certain fabric parameters, as may be necessary for small-order lots and varying styles in

accordance with customer market requirements.

Through the application of state-of-the-art electronics, settings that have once been

defined for a fabric can be stored on data carriers and loaded back onto the control unit of

weaving systems. The possibilities for on-line process control mechanisms can optimally be

exploited only if machines have elements that can convert electrical signals into corresponding

weaving technological functions.

Such elements have, for quite some time now, proved successful in the form of servo, stepper

and, lately, linear motors; or as lifting and stepping magnets. Advanced solutions have been found

for controlling thread clamps of filling yarns to be presented to the rapier.

This means that on rapier machines, it is now possible to weave without any filling and warp

waste on the insertion side.

In summary, it can certainly be established that process control in weaving has become a

reality. Its degree of complexity results from the need to continuously reduce costs, and to

improve quality – but also from the limits of present technologies applied in the industry.

Editor’s Note: Fritz Legler is president of Sultex (USA) Inc., Spartanburg, a division of

Sultex Ltd., Switzerland, and member of the Itema Group, Italy.