PARIS — February 6, 2024 — Each year, JEC World creates an engaging conferences program that enables attendees to tackle the main challenges and significant developments influencing the future of the worldwide composites industry.

PARIS — February 6, 2024 — Each year, JEC World creates an engaging conferences program that enables attendees to tackle the main challenges and significant developments influencing the future of the worldwide composites industry.

By spotlighting emerging composites markets globally and examining new materials, products, and processes, this carefully crafted program encourages executives and engineers at every stage of the supply chain to exchange insights. It offers a comprehensive set of resources to comprehend the industry’s future trajectory and capitalize on distinctive opportunities for international business expansion.

By spotlighting emerging composites markets globally and examining new materials, products, and processes, this carefully crafted program encourages executives and engineers at every stage of the supply chain to exchange insights. It offers a comprehensive set of resources to comprehend the industry’s future trajectory and capitalize on distinctive opportunities for international business expansion.

Sustainability Conferences

In 2024, sustainability is still a key growth driver for the composites industry, enabling diverse application sectors to achieve ambitious sustainability goals thanks to recycling, lightweight, bio-based materials, digitalization and more.

March 5th 12.00-13.00 – Agora 5 (Hall 5)

Unleashing the Power of Nature: Exploring Natural Fibers and Bio-Sourced Materials in the Composites Industry

Speakers:

- Mr Remi DAUDIN, President MATERI’ACT – FORVIA

- Dr Christian FISCHER, CEO & Co-Founder – BCOMP AG

- Mr Christoph GEYER, CEO – SAERTEX GMBH & CO KG

- Dr Martin JENSEN, CTO – Pond A/S

- Mr David SALTMAN, Chairman & CEO – INCA Renewable Technologies Inc.

- Mr Corey TYREE, CEO – Trillium Chemicals

Moderator: Prof Ignaas VERPOEST, Emeritus Professor – Composite Materials Group, KU Leuven

March 5th 15.00-15.55 – Agora 5 (Hall 5)

Circularity meets Lightweight Design for the Future of Automotive

Speakers:

- Dr Stefan CABA, Head of Innovation Field Sustainable Vehicle Development – EDAG Engineering GmbH

- Prof Ahmed ELMARAKBI, Professor – Northumbria University at Newcastle

- Dr Thomas HIPKE, Division Director – FRAUNHOFER IWU

- Dr Thierry RENAULT, Senior Expert Composites – FAURECIA AUTOMOTIVE COMPOSITES

- Dr Violeta VARGAS-PARRA, Researcher – Eurecat, Centre Tecnològic de Catalunya

Moderator: Dr Ricardo del VALLE, Senior Innovation Consultant – Bax and Company

March 6th 12.00-13.00 – Agora 5 (Hall 5)

Revolutionizing Composites: The Benefits and Challenges of using Recycled Materials

Speakers:

- Dr Erwan FAOUCHER, Sustainability, Research and Innovation Director – Beneteau

- Mr Andrew GOODMAN, CSR Manager – SCOTT Sports

- Mr Ross HOOD, Director, Composite Manufacturing – McLaren Racing

- Mr Andrew MAXEY, CEO – Vartega Carbon Fiber Recycling LLC

- Mr Guillaume PERBEN, CEO – COMPOSITE RECYCLING

Moderator: Mr Malcolm FORSYTH, Sustainability Manager – COMPOSITES UK

March 7th 12.00-13.00 – Agora 5 (Hall 5)

Composites Manufacturing 4.0: Unlocking Efficiency and Sustainability Through Automation & Digitalization

Speakers:

- Mr Avner BEN BASSAT, President & CEO – PLATAINE LTD

- Ms Cornelia BEYER, Managing Director – Netzsch Process Intelligence GmbH

- Dr Jose FEIGENBLUM, Innovation Director – ROCTOOL S.A.

- Dr Enrique GARCIA, Chief Technology Officer – National Composites Centre UK

- Mr Mitchell SMITH, Director of Technology and Process Engineering – MRA Systems LLC

Moderator: Mrs Hannah DAMMERS, Head of Composite Production Division – Institut fuer Textiltechnik of RWTH Aachen University

End-user Applications Conferences

March 5th 14.00- 14.55 – Agora 6 (Hall 6)

Composite Materials and Sustainable Transportation: Paving the Way Forward

Speakers:

- Mr Andrea FAGGIANI, Head of Composite Materials and Technologies Centre – Automobili Lamborghini S.p.A.

- Dr Philippe PAPIN, Project Manager – AIR LIQUIDE

- Mr Baptiste ROSSI, VP Engineering – AYRO

Moderator: Mr Dale BROSIUS, Chief Commercialization Officer – IACMI – THE COMPOSITES INSTITUTE

March 6th 14.00- 14.55 – Agora 6 (Hall 6)

Beyond Boundaries: Composite Materials Shaping the Aerospace Industry

Speakers:

- Dr Emma CLAXTON, Programme Manager – UltraFan Fan Rig Validation – Rolls-Royce plc

- Mr David PATE, Head of Materials and Processes – Lilium

- Dr Stephanie PATEL, Head of Material – Expert – DAHER

Moderator: Mr Marc FETTE, CEO – Composite Technology Center (An AIRBUS Company)

March 7th 14.00- 14.55 – Agora 6 (Hall 6)

Composite Materials in Wind Energy Today and Tomorrow – Pathways to 100% Circularity

Speakers:

- Mr Mathieu CARIOU, Director – Strategic Corporate Development & MarCom – GURIT

- Mr Guillaume CLEDAT, Elium Business Director – ARKEMA

- Dr Leif Ole MEYER, Global Wind Technology Platform and EMEAI R&D Leader – Olin Germany Upstream

- Mr Allan POULSEN, Head of Materials and Sustainable Scaling – Vestas Wind Systems

- Dr Tom WASSENBERG, Director Strategic Marketing Wind – OWENS CORNING

- Mr Peter WINDMOELLER, Senior Sales Manager – LOESCHE

Moderator: Mr Alexander VANDENBERGHE, Sustainability Manager – WindEurope

The best of innovation and entrepreneurship

- The JEC Composites Innovation Awards

In more than 25 years, the JEC Composites Innovation program has involved more than 2,000 companies worldwide. 225 companies and 573 partners have been awarded for the excellence of their composites innovations.

Eleven winners were named on February 8th : they will be joining the opening speech on March 5th from 9:30 am in Agora 5 (Hall 5). Don’t miss this opportunity to meet with them and their partners!

JEC Composites Innovation Awards partner

- The JEC Composites Startup Booster

The leading startup competition in the world of composites is set to host 20 pre-selected finalists, who will present their projects live before a panel of industry experts. The jury will select three winners overall, including a special award for the project demonstrating outstanding sustainability.

March 5th 10.00 – 11.25 AGORA 6 (Hall 6)

Pitching Session – “Products & Materials” Category

Startups:

- BioHalo (Denmark)

- BioTwin (UK)

- CARBOCON (Germany)

- Cellexcel (UK)

- High Temperature Material Systems (UK)

- Nano Electronics (South Korea)

- RECARBON (Italy)

- Sargassum Eco Lumber (USA)

- SpacEngineer (Portugal)

- ZILA BioWorks (USA)

March 5th 16.30 – 17.55 AGORA 6 (Hall 6)

Pitching Session – “Process, Manufacturing & Equipment” Category

Startups:

- CarboScreen (Germany)

- Componous (Greece)

- Eddytec (Netherlands)

- Elementag (Italy)

- fiberior (Germany)

- Holy Technologies (Germany)

- MOB-E-SCRAP (France)

- REINFORCE3D (Spain)

- TechnoCarbon Technologies (France)

- 3P.COM (South Korea)

March 6th 15.30- 15.55 AGORA 6 (Hall 6)

Startup Booster Awards Ceremony

Country on stage

In-depth presentations and discussions on the composites industry in specific countries and regions.

March 5th 10.00 – 11.25 – Agora 5

Belgian Composites for a Sustainable Future

Speakers:

- Mr André BERTIN, CEO – COEXPAIR

- Mrs Linde DE VRIESE, Project Leader Circular Economy Composites & Renewable Materials – Sirris

- Dr Stephane GUALANDRIS, Project Manager – Skywin Wallonie

- Dr Laurent HAZARD, Head of Material Science & Application Center – Syensqo

- Mrs Martine LECLERCQ, Trade and Investment Counsellor – Wallonia Export & Investment Agency (AWEX)

- Mr Johan POTARGENT, CEO – AMS Robomould

- Mr Wim SIX, R&D Project Manager – Deceuninck

- Miss Lucie SOUVY, Project Manager & Quality System Management Responsible – ISOMATEX S.A.

- Mrs Karolien VANBROEKHOVEN, Research Manager Sustainable Chemistry – VITO

- Mr Jan VERHAEGHE, CEO – AGESIA

Moderator: Dr Kevin POELMANS, Business Group Leader Agoria Composites – AGORIA

March 6th 10.00 – 11.25 – Agora 5

How Italy is Making the Composites Market of Tomorrow: Innovations and Dynamism

Speakers:

- Prof Luigi ASCIONE, Retired Professor of Structural Mechanics at the University of Salerno (Italy) – Convenor of WG 4 of CEN-TC 250 – University of Salerno

- Dr Vincenzo CASTORANI, R&D Project Manager – HP Composites S.p.A.

- Dr Andrea RATTI, Associate Professor – Politecnico di Milano

Moderator: Prof Roberto FRASSINE, President – ASSOCOMPOSITI

March 7th 10.00 – 11.25 – Agora 5

Competitiveness and Innovation in the French Composites Industry Through the “France 2030” Relaunch Plan

Speakers:

- Mr Nicolas ABIVEN, President – SolidSail Mast Factory – Chantiers de l’Atlantique

- Mr Mathieu BRANDIBAT, Senior Advisor for Critical & Sustainable Materials – General Secretariat for Investment (SGPI)

- Mr Arnaud CACQUEVEL, Marketing Manager – Innovation – Bretagne Développement Innovation

- Mr Thibault GARIN, CEO – MerConcept

- Mr Jean-François GERARD, Deputy Scientific Director of CNRS Chemistry – French National Center for Scientific Research (CNRS)

- Mr Roland JOURDAIN, Skipper & CEO – Kaïros

- Mrs Marie-Cécile TARDIEU, COO – Business France

Moderator: Mr Antoine THEVENIN, Key Account Manager – Business France

Women in composites

March 7th 11.00 – 11.55 – Agora 6

Building a Supportive Community for Women in the Composites Industry

Speakers:

- Trupti ARABATTI, CEO, Sustainable Materials Specialist – Terra Stems

- Shelly BENNION, General Manager – Hawkeye Industries, LLC

- Ümmühan EKER, R&D Director – DowAska

- Anna GALASSO, Ravenna Shipyard Plant Director – Ferretti SpA

- Joannie HARMON, Vice President, Workforce Development – IACMI – THE COMPOSITES INSTITUTE

Moderator: Marcy OFFNER, Director, Marketing Communications – Composites One

CAMPUS

Careers in the composites industry have much to offer and need to be highlighted. On April 27th, JEC World invites all universities, training programs, students, HR representatives, to gather and foster recruitment and training in this thriving sector.

Tuesday, March 5th – CAMPUS VILLAGE

10:00-10:20: Nantes Université, Christophe BINETRUY, Professor at Centrale Nantes, VP for Entrepreneurship

10:30-10:50 : Politecnico di Milano, Luca M. MARTULLI, Assistant Professor

11:00-11:20: University of Tokyo, Nobuhiro YOSHIKAWA, Professor at University of Tokyo, Institute of Industrial Science

11:30-11:50: Tu Dresden, Daniel KOHLER, Research Assistant

12:30-13:00: Space Team Aachen, Richard BOTSCHEK Structures Team Lead & Dominik NEUMANN Structural Engineer

14:00-14:20: University of Patras, Dr. Stavros TSANTZALIS, Research Project Manager, or Prof. Vassilis Kostopoulos, Head of Mechanical Engineering and Aeronautics Dept. and director of Applied Mechanics and Vibrations Laboratory

14:30-14:50: ExpertHeads Consulting, Christian THOBEN, Managing Director

15:00-15:20: DS Talent Recruitment – Antal: Arnaud SPORTOUCH, Executive Senior Recruiter

15:30-15:50: Fluency People, Glenn HARDY, Director

16:00-16:20: Enercomp, Gilles LUBINEAU, Director of ENERCOMP & Professor of Mechanical Engineering at KAUST/ Mechanics of Composites for Energy and Mobility Lab.

16:30-16:50: KFUPM

Wednesday, March 6th – CAMPUS VILLAGE

10:00-10:20: Tu Dresden, Daniel KOHLER, Research Assistant

10:30-10:50: EPFL, Véronique MICHAUD, Head of laboratory for processing of advanced composites.

11:00-11:20: Space Team Aachen, Richard BOTSCHEK Structures Team Lead & Dominik NEUMANN Structural Engineer

11:30-11:50: University of Patras, Prof. Vassilis KOSTOPOULOS, Head of Mechanical Engineering and Aeronautics Dept. and director of Applied Mechanics and Vibrations Laboratory

12:00-12:20: Nantes Université, Christophe BINETRUY, Professor at Centrale Nantes, VP for Entrepreneurship

12:30-13:00: Politecnico di Milano, Luca M. MARTULLI, Assistant Professor

14:00 -14:20: University of Tokyo, Nobuhiro YOSHIKAWA, Professor at University of Tokyo, Institute of Industrial Science

14:30-14:50 : 6C32 DAHER, Lucas PETRY, Industrial Services Talent Acquisition Manager

15:00-15:20: ExpertHeads Consulting, Christian THOBEN, Managing Director

15:30-15:50: DS Talent Recruitment – Antal: Arnaud SPORTOUCH, Executive Senior Recruiter

16:00-16:20: Fluency People, Glenn HARDY, Director

16:30-16:50: 6S42 KU LEUVEN, Yentl SWOLFS, Research Professor

Thursday, March 7th- CAMPUS VILLAGE

10:00-10:20 University of Tokyo, Nobuhiro YOSHIKAWA, Professor at University of Tokyo, Institute of Industrial Science

10:30-10:50: Tu Dresden, Daniel KOHLER, Research Assistant

11:00-11:20: EPFL, Véronique MICHAUD, Head of laboratory for processing of advanced composites.

11:30-11:50: KFUPM

12:30-13:00: University of Patras, Dr. Stavros TSANTZALIS, Research Project Manager, or Prof. Vassilis KOSTOPOULOS, Head of Mechanical Engineering and Aeronautics Dept. and director of Applied Mechanics and Vibrations Laboratory

14:00-14:20: Space Team Aachen, Richard BOTSCHEK, Structures Team Lead & Dominik NEUMANN, Structural Engineer

14:30-14:50: Enercomp, Gilles LUBINEAU, Director of ENERCOMP & Professor of Mechanical Engineering at KAUST/ Mechanics of Composites for Energy and Mobility Lab

Live Demonstration Area

The Live Demonstration Area showcases composite parts manufacturing processes, with four experts of the industry Aerovac- Composites One, Magnum Venus Products, Thermwood and Roctool.

Fast Induction Heating Molding of Composite Thermoplastics: Thermocompression Molding with Roctool Heat and Cool Technology

Speakers:

- Mr Mathieu BOULANGER, CEO – ROCTOOL S.A.

- Mr Edouard PHILLIPE, Composite Business Development Manager – ROCTOOL S.A.

March 5th – 10.00-10.30

March 5th – 12.15-12.45

March 5th – 16.15-16.45

March 6th -10.00-10.30

March 6th -12.15-12.45

March 6th -16.15-16.45

March 7th – 11.30-12.00

Process Material Kits Finish First by Offering Real Time Savings

Speakers:

- James KNOX, Technical Services Manager – Aerovac Composites

- James JONES, Lead Technical Support Manager – Composites One

March 5th -10.45-11.15

March 6th – 14.45-15.15

March 7th – 10.00 – 10.30

Mastering Closed Mold Silicone Bag Construction

Speaker:

- Charles TUR, Closed Molding Specialist – MVP

March 5th -10.45-11.15

Exploring LSAM – Thermwood’s Large Scale Additive Manufacturing System

Speakers:

- Mr Eduardo BAROCIO, Assistant Director of Additive Manufacturing – Purdue University – CMSC

- Mr Scott VAAL, LSAM Product Manager – THERMWOOD CORP

March 5th -14.00-14.30

March 6th – 14.00-14.30

Save Time, Money, and Effort with Vacuum Infusion and Custom Process Material Kits from Aerovac

Speakers:

- Mr James JONES, Lead Technical Support Manager – Composites One

- Mr James KNOX, Technical Services Manager – Aerovac Composites

March 5th -14.45-15.15

March 6th – 11.30-12.00

Revolutionizing Closed Molding with SVB Seal Technology

Speaker:

- Charles TUR, Closed Molding Specialist – MVP

March 5th -15.30-16.00

Precision Injection with Collapsible Resin Channel in Silicone Bags

Speaker: Charles TUR, Closed Molding Specialist – MVP

March 6th – 10.45-11.15

Injecting Collapsible Resin Channel with SVB Seal

Speaker: Charles TUR, Closed Molding Specialist – MVP

March 6th – 15.30 – 16.00

Achieve Rapid Injection Times and Higher Quality Parts with Fast Flow LRTM

Speaker: Charles TUR, Closed Molding Specialist – MVP

March 7th – 10.45 – 11.15

Closed Mold Methodologies Reviewed for Optimal Results

Speaker:

- Charles TUR, Closed Molding Specialist – MVP

March 7th – 12.15-12.45

Composites Exchange

The Composites Exchange are a dedicated program of exhibitors’ and partners workshops, showcasing products, solutions, and business cases.

March 5th

AGORA 5 (Hall 5) SYENSQO / DASSAULT SYSTEMES / EXXONMOBIL / ALLIANCE FOR EUROPEAN FLAX-LINEN & HEMP / HRC / SGL CARBON

AGORA 6 (Hall 6) SWANCOR / sensXPERT / MASSIVIT / BODO MÖLLER CHEMIE GMBH / OCSIAL Europe / IMCD /

March 6th

Agora 5 (Hall 5) SYENSQO / DASSAULT SYSTEMES / EXXONMOBIL / SYENSQO / POLYCELL SRL / VON ROLL MANAGEMENT AG /DIEFFENBACHER GMBH MASCHINEN- UND ANLAGENBAU / THE JAPAN CARBON FIBER MANUFACTURERS ASSOCIATION

AGORA 6 (Hall 6) ECODEC / DISTRAN / HUNTSMAN ADVANCED MATERIALS / HELD TECHNOLOGIE GMBH / ARKEMA / NIONE LTDA / FORMOSA PLASTICS CORPORATION / TESTIA / WESTLAKE EPOXY /

March 7th

AGORA 5 (Hall 5) FAIRMAT

AGORA 6 (Hall 6) COMEC INNOVATIVE / PENTAXIA / MITSUBISHI ELECTRIC CORPORATION / MEDC

Posted: February 6, 2024

Source: JEC Group

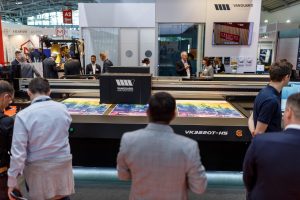

AMSTERDAM — February 7, 2024 — Vanguard Europe has announced its presence at FESPA Global in Amsterdam, where it will share a booth with its strategic partner, Pixia BV March 19-22, 2024.

AMSTERDAM — February 7, 2024 — Vanguard Europe has announced its presence at FESPA Global in Amsterdam, where it will share a booth with its strategic partner, Pixia BV March 19-22, 2024. Founded 14 years ago, Pixia has a strong background in large format print media, laminates, magnetic- and interior films, servicing signmakers as well as large online print service providers.

Founded 14 years ago, Pixia has a strong background in large format print media, laminates, magnetic- and interior films, servicing signmakers as well as large online print service providers.