F

ollowing are some of the most recent developments in the field of weaving machines and

accessories, destined to increase weaving mill productivity, while at the same time achieving

significant savings in labor and energy.

Dornier

Lindauer Dornier GmbH, Germany, used this year’s International Textile Machinery Trade Fair

(ITMEX Americas) 2005 in Sao Paulo, Brazil, as a platform to emphasize its drive in technological

progress. New developments cover the complete weaving machine product line. The new performance

generation of air-jet and rapier weaving machines; and the ServoTerry® machine for terry weaving

are complemented by innovative advances in leno technology with the EasyLeno® weaving machine for

technical and decorative fabrics.

ServoTerry is used in the home textiles sector. Its advantage over existing systems is its

direct drive for terry movement using a servomotor while retaining precise but gentle reed impact.

This allows varying pile weave and adjustable pile heights during operation. The 260-centimeter

(cm)-wide machine is equipped with a Staubli dobby with 16 shafts for the production of three-width

terry bath towels at varying speeds of 540 and 600 revolutions per minute (rpm).

Other developments include the AS air-jet weaving machine, which runs with new, patented

ServoControl® pressure regulation. This minimizes thread load and allows automatic, reproducible

pressure adjustments for yarn lot changes to be made, and ensures higher performance with improved

final fabric quality, according to Dornier.

Another recent development is the AirGuide® patented air cushion guide for Dornier rapier

weaving machines. The linear movement of the rigid rapier rod is ideal for this new system – the

perfect technical solution for contact-free, aerostatics support.

The EasyLeno system for rapier and air-jet weaving machines enables up to 100-percent higher

performance in leno technology, and opens up options for completely new fabric design in the

technical textiles and home furnishings sectors.

Jakob Muller

Jakob Muller AG, Frick, Switzerland, offers weaving machines for the production of patterned

elastic and non-elastic narrow fabrics and lace articles, including satin ribbons and tapes. Its

needle weaving machines include models such as the NF, NG and Varitex V5Ni.

The company has improved the NF model, which now is able to insert up to six weft colors,

substantially increasing weft pattern options. The choice of weft colors is practically unlimited.

Length changes are achieved by electronic single heddle control, programmed and controlled via the

Mudata system.The NG3 model is equipped with a Quick-Style-Change system for reeds, heddles, drop

wires and heddle frames; this option also is offered for the warp frame beam. The NG3 is designed

to provide optimum performance for belts, and non-elastic and elastic fabrics.

Picanol

Picanol NV, Belgium, manufactures several kinds of high-tech weaving machines for different

applications in the textile industry. The OMNIplus air-jet machine for the weaving of staple

fibers, filament, high-twist yarns, elastic yarns, chenille and texturing yarns, among others, uses

up to six colors and different types of fillings.The OMNIplus comes in reed widths of 190, 220,

250, 280, 340, 380 and 400 cm. It can produce fabric rolls 720 millimeters (mm) wide, or up to

1,500 mm wide with Picanol’s separate Picanol Batching Motion system for rolling of fabric.

Other advantages include digital adjustments and synchronization of the complete weft insertion

cycle; a separate frame for style change in less than 30 minutes; a high level of weft insertion

performance, allowing more weaving using less air; rapid change of the roll and the warp; low

construction with ergonomic characteristics; and a Sumo main motor for the direct drive of the

machine.

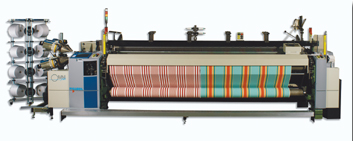

Picanol’s OMNI

plus air-jet weaving machine is available in a variety of reed widths.

Promatech-Itema Group

Promatech S.p.A., Italy (formed by the merger of Somet and Vamatex), is a member of the Itema

Group, also based in Italy. It is well known for its line of rapier and air-jet weaving machines,

including models such as the Mythos, Thema Super Excel and Alpha (from Somet); as well as the

Leonardo and K88 (from Vamatex).

The latest developments from Promatech include the high-speed, versatile Mythos Tec air-jet

weaving machine. Recently, the company sold several of these machines to a textile manufacturer in

Brazil.

Promatech’s Alpha 3200 negative rapier weaving machine is available with a jacquard machine for

double width for use in upholstery production.

Other weaving machines offered by Promatech include the Alpha 2200, equipped with dobby suitable

for the production of high-quality woolen fabrics; the FTS, which works without using hooks and is

suitable for a variety of applications; and the Leonardo Silver, which is equipped with a rapier

guidance system.

SMIT

SMIT S.p.A., Italy, is an international leader in weaving machine technology, supplying

cutting-edge products and prompt and effective after-sales support.

Numerous weaving machine models have been developed since the company introduced the first

gripper weaving machine. These models include the TS, TP, TTPS, FAST, TerryJet, GS900, JS900, G6300

and G6300F models.

(See “SMIT Solutions,”

www.TextileWorld.com, March 2005).

Staubli

Switzerland-based Staubli AG’s range of shedding machines and accessories is extensive and

covers all fields. The range includes cam motions, negative dobbies and rotary dobbies; as well as

high-performance harness motions, quick links and frames. Depending on the type of machine,

mechanical controls by cams or electronic controls are used.

Staubli dobbies are simple and user-friendly. The company offers dobbies adapted to all types of

weaving machines and all weft insertion systems, as well as for the production of all types of

fabrics from basic fabrics to technical fabrics and double-pile fabrics and carpets.

The CX 160 electronic jacquard machine is particularly suitable for personalizing flat fabrics

with written selvages. It may be equipped with up to 96 hooks, enabling great production

flexibility.

The CX 990 is a double-lift jacquard machine used in the production of carpets and velvet

fabrics. It is equipped with the CX modulus (Staubli Patent), which does not require any

maintenance, according to the company.

The Delta automatic drawing-in machine is known throughout the world and has demonstrated its

capability in many diverse applications. One of the main advantages of this system is the

reduction of labor costs owing to automation and rationalization, with great flexibility to adapt

to varying needs of the market.The Topmatic tying machine guarantees maximum efficiency during the

warp change process. The use of all yarn types and optimum tying quality lead to minimum

downtime.Stlis Warplink warp welding device enables the laying-in and start-up weaving of newly

drawn-in or stationary tied warps to be accelerated and simplified. The company reports resultant

time savings at style change may exceed 30 minutes.

Staubli’s Topmatic tying machine helps makethe warp change process more efficient.

Sultex-Itema Group

The Sulzer Textil G6500 from Switzerland-based Sultex Ltd. – another member of the Itema Group –

continues the company’s long tradition in rapier technology. With its many innovative features,

this machine stands apart thanks to its performance, gentle handling of warp and weft materials,

compact dimensions and economically efficient production of top-quality fabrics, according to

Sultex.

This new rapier weaving machine already is producing successfully under industrial conditions in

several weaving mills around the world. The machine is offered with several options; its main

characteristics are sturdiness and flexibility.Sultex also offers the G6500 B220 N8/4 SP, a machine

of very high production speed and low vibration levels.The company’s newest machine is the L5500

air-jet weaving machine, which it introduced at ITMEX Americas 2005

(See “Sultex Debuts L5500 Air-Jet Machine At ITMEX,”

www.TextileWorld.com, this

issue).

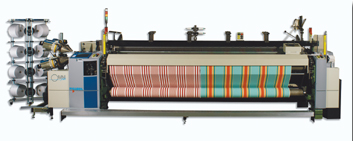

The Sulzer Textil G6500 features compact dimensions, and gentle handling of warp and weft

materials, according to Sultex Ltd.

Toyota

The JAT710 air-jet weaving machine manufactured by Toyota Industries Corp., Japan, was designed

along the same lines as its predecessor, the JAT610, to produce high-quality fabrics at the lowest

possible cost. The machine features such characteristics as a higher speed, reduced vibration and

low energy consumption.

The machine comes equipped with the latest in electronic technology, including a new panel for

the control of colors, and has the capability to be connected to the Internet.The main features of

the JAT710 are: reduced air consumption by up to 20 percent; maximum speed of up to 1,250 rpm due

to a new weft insertion system and new frame structure; and a central processing unit.

The JAT710 air-jet weaving machine from Toyota Industries may be connected to the

Internet.

Tsudakoma

Tsudakoma Corp., Japan, offers its ZAX-e air-jet machine equipped with an iT control panel. This

panel automatically adjusts several machine functions. The easy-to-use iT panel has a touch-screen

feature with color display interface that automatically adjusts data and diagnoses problems.

New, built-in electromagnetic valves stabilize the air jet and the pressure pulse. New

sub-nozzles contribute to significant savings in energy, even at high operating speeds.

Van de Wiele

NV Michel Van de Wiele, Belgium, a manufacturer of weaving machines for carpets and other

applications, offers new machine models such as the Shaggy Rug eXplorer SRX82; the Carpet and Rug

eXplorer with eight color frames; and a machine for the manufacture of sisal-look carpet with

visible fillings of different colors and cut pile.

March 2005

Contending

Contending