Here is the next of the previews of exhibitors at ITMA 2011 in Barcelona, Spain. In this issue, the

Rupp Report is looking at Switzerland-based Jakob Müller AG, Frick, a leading supplier of narrow

weaving machinery. The Rupp Report contacted Eduard Strebel, manager, marketing communications,

posing the same questions as in the previous reports.

Global Activities And Markets

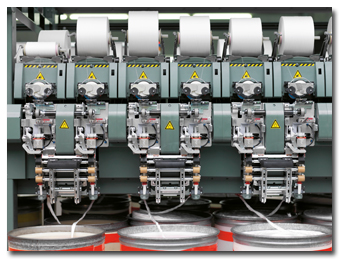

The family-owned company, founded in 1887, has evolved from a traditional company to a

globally active enterprise with production sites in Switzerland, Germany, the Czech Republic, China

and India. The production program includes machines for woven and warp-knitted ribbons, belts and

other narrow fabrics.

Jakob Müller also maintains offices for sales and services around the globe — in the United

States, Canada, Mexico, Brazil, Japan, China, Hong Kong, India and Germany. Almost 100 percent of

the machinery produced is exported — to be precise, it’s 99 percent. “Sales are quite even across

the whole portfolio. We have no top seller at the moment,” Strebel said. He claims that Jakob

Müller is the market leader in various segments of the narrow fabrics industry.

And how does Strebel judge the current market situation? “Well, we have mixed emotions, and

for the time being, we are carefully observing the situation. The circumstances in the global

economy are somewhat insecure and even more severe for us as a Swiss machinery manufacturer due to

the extremely strong Swiss franc,” he said.

ITMA Barcelona

Some 50 people comprise the team that will be at ITMA in Barcelona. “We expect about the same

number of visitors as in Munich four years ago — however, some will come from different markets

than in Germany,” Strebel said. “Furthermore, we expect some hesitation from the visitors as to

eagerness to invest in new machinery in view of the current market situation.”

Jakob Müller invited its global clientele using direct mail, among other means. Strebel

judges the cooperation with the organizers of the fair to be excellent. “And for once,” he said,

“the strong Swiss franc is an advantage for Swiss exhibitors; we pay our square meters in euros.”

The Future

What are Jakob Müller’s targets in the near future? “We want to extend our leadership as a

premium supplier for the ribbon and narrow fabrics industry,” Strebel said.

And how does he judge developments in the coming years? “There will be certainly an increased

price fight due to overcapacities in the markets,” Strebel said. “On top of that, and this is not a

secret, there is increased importance and awareness for technical textiles in Europe; and an

ongoing shift of apparel manufacturing to Turkey, India, Bangladesh, Vietnam and Latin America.”

September 6, 2011