FRANKFURT, Germany — October 14, 2024 — With 42 exhibiting member companies, ITMA ASIA + CITME 2024 is once again marked by a strong presence of VDMA companies. They cover nearly all different machinery chapters with a focus on spinning and man-made fibers, nonwovens, weaving, braiding, knitting & warp knitting, finishing & dyeing as well as technologies for textile recycling and processing of recycled material.

FRANKFURT, Germany — October 14, 2024 — With 42 exhibiting member companies, ITMA ASIA + CITME 2024 is once again marked by a strong presence of VDMA companies. They cover nearly all different machinery chapters with a focus on spinning and man-made fibers, nonwovens, weaving, braiding, knitting & warp knitting, finishing & dyeing as well as technologies for textile recycling and processing of recycled material.

In total, the German participation at the fair is the largest from outside China.

China is aiming at a green and low CO2 development of its textile industry. At a press conference on the first day of ITMA ASIA + CITME, Georg Stausberg, member of the board of VDMA Textile Machinery and CEO of the Oerlikon Polymer Processing Solutions Division said: “Topics, such as energy efficiency and the careful use of resources have become increasingly important for Asian customers in recent years, not least due to stricter legal framework conditions. VDMA members and their technologies are the right partners on the road to a greener and low CO2 textile production.”

Export performance

Already in 2023, the global textile machinery exports decreased by 18.6 percent compared to 2022. This was a challenge all major textile machinery producing countries had to face. However, the German exports remained relatively strong and only declined by 3.4 percent in 2023. 2024 did not see a change in the global textile industry and thus the German exports have now also dropped significantly. Between January and July 2024, German exports of textile machinery and accessories summed up to 1.2 billion euros (2023: 1.6 billion euros). The shipping to almost all major markets decreased between January and July: China: 242 million euros (2023: 384 million euros), Turkey: 140 million euros (2023: 180 million euros), USA: 118 million euros (2023: 152 million euros), India: 100 million euros (2023: 153 million euros).

Sales opportunities in Asia

An economic survey of VDMA in September, to which 20 textile machinery companies replied, reflects the global challenging situation. Around 36 percent assessed their current business situation as satisfactory, 54 percent said it was bad. Only very few companies expect the global situation to improve in the next six months.

However, looking at the sales opportunities by regions/countries in Asia, most of the responding companies expect a better business situation in the Asian markets except China in six months. The business situation is expected to be on a satisfactory level then. With regard to this, a presence at ITMA ASIA in Shanghai and next year in Singapore is important for VDMA members to continuously show their innovations and to keep contact with the customers in Asia.

The contribution of leading VDMA members and their technologies to a green textile production:

The presence of VDMA at this year’s ITMA ASIA + CITME is themed Smart technologies for green textile production.

Here are examples of exhibitors that stand for the entire industry:

Georg Stausberg, CEO of Oerlikon Polymer Processing Solutions Division stated:

“China continues to have enormous potential for us, even if it has not been able to match the previous times in terms of large new installations of manmade fiber plants and the associated expansion of production capacity for good two years. However, there is still a great need for renewal, especially in terms of sustainability. Shutting down old plants and replacing them with new and energy-efficient technologies is the path to a better and lower-emission future for us all. We have been contributing to sustainability with our technology solutions for decades. Be it by increasing energy efficiency with each new generation of machines or by processing new materials. Oerlikon is proud of the fact that we have been offering innovative solutions under the e-save sustainability label for 20 years and has saved over 15 million tons of CO2 thanks to the machines and systems developed and installed on the market during this time.”

Hailin Xu, CEO Saurer Group said: “Processing recycled and regenerated fibres is becoming increasingly important worldwide. Saurer is a key enabler of the transformation towards a more circular textile business. The product portfolio today includes energy efficient machinery for spinning and twisting yarns from recycled fibres. To enable customers to process extremely short fibres, we continue to develop special solutions, which are also available as retrofits for older machines. In addition, our machines have been developed to reduce energy consumption and maximise raw material utilisation. It’s all about saving resources”.

Dr. Axel Hannemann, head of business unit fiber and pellets, Gneuss Kunststofftechnik explained: “As sustainability becomes more important, fibre producers are shifting towards recycled PET materials, including post-consumer PET bottle flakes and manufacturing waste. However, the increasing demand for PET bottle flakes has led to a scarcity of affordable, high-quality flakes. One challenge in recycling polyester is moisture absorption, which can weaken the polymer during extrusion. Recycling PET fibres, particularly industrial waste, is also difficult due to low bulk density, residual moisture, and spin finish oils. Gneuss offers tailored solutions to address these challenges efficiently.”

On behalf of Karl Mayer Group, Christine Wolters, vice president corporate communications said: “At ITMA ASIA, we are showcasing solutions that support both sustainability and the profitability of our customers. A key focus is on energy consumption: In the warp knitting sector, we present an energy efficiency solution that reduces the power usage of our machines. In warp preparation, we have optimized drying processes for more efficient energy use. Energy, cost, and CO2 savings can be monitored live. Another highlight: Our digital products improve processes with positive impacts on both sustainability and costs”.

“Groz-Beckert’s innovative textile tools enhance energy efficiency in textile manufacturing, driving down production costs. A key development is the introduction of a ‘pay-per-use’ pricing model for tools, which allows companies to align expenses with actual tool usage. This enables manufacturers to better handle demand fluctuations, reduce investment risks, and improve resource management. By focusing not only on product innovation but also on service offerings, Groz-Beckert is advancing both efficiency and sustainability in textile production” stated Eric Schöller, member of the executive board, Groz-Beckert.

Dennis Behnken, managing director of the company Herzog, the most innovative developer and manufacturer of braiding and winding machinery noted: “At Herzog GmbH, we rely on smart technologies to make textile production more sustainable. By using digital solutions, intelligent automation and high production quality, we reduce resource consumption and minimize waste. In this way, we make our contribution to a greener future without compromising on the quality of our products.“

“Customer requirements are rising and skilled staff is becoming scarce. Technologies like sensors and control systems are increasingly important for efficient operation and quality assurance”, Kathrin Pleva, member of management of Pleva GmbH said and continued: “Our process control system PLEVATEC smart is designed to meet exactly those needs. It improves operation at stenters and other drying processes with sensor modules. It enables our customers easy operation to produce faster, save resources and improve product quality and reproducibility. Similarly, our weft-straightener SL smart is easy to operate and maintain while delivering perfect straightening results.”

Tallen Yang, Sales Director Erhardt + Leimer China stated: “Currently, many textile companies are facing challenging times. The lack of turnover, however, is giving room for improvements. How much money can be saved by a proper fabric guiding, that avoids stoppages due to insufficient pinning? How many tons of fabric can be saved by an intelligent, AI-based edge cutting? How much energy can be saved by an optimized stenter management? The time for all these questions is now. And the place for answers is the booth of E+L, leading in process optimization for more than 100 years.”

According to Clemens Kaplan, product manager at Mahlo, a German manufacturer of measuring, control and automation systems for the textile and finishing industry, today’s increasing quality standards require intelligent, AI-supported process and quality management systems. Kaplan said: “As always, Mahlo is ahead of the curve and has reinvented the concept of weft straightening for the second time. The latest straightening technology, Orthopac RXVMC-20, with an AI-supported feed-forward algorithm, paired with a modular process control system, Optipac, revolutionizes straightening from the ground up. Residual distortions and fluctuations in key parameters such as residual moisture, exhaust air humidity, thread density, fabric weight, fixation dwell time, fabric width, liquor pick-up, etc., are now definitively a thing of the past thanks to this new technology.”

For the company SETEX, provider of MES production management software and control systems for textile machines, CEO Oliver Schermuly stated: “Manufacturers need a single source of truth for production data. By integrating all KPIs — from costs to carbon footprint — we provide clarity and enable optimization of production processes. Our SETEX controllers ensure seamless machine communication, capturing robust real-time KPIs. This interaction allows fine-tuning, maximizing machine potential beyond standard MES functions into advanced manufacturing excellence. AI-powered smart recipes reduce waste and boost efficiency. Unified data enhances productivity, supports digital product passports, and drives digitalisation for smarter, more sustainable production. Together, we’re creating a single source of truth to build a better, greener world.”

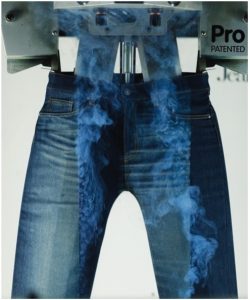

Tobias Schurr, member of the management board of Weitmann & Konrad explained: “Textile producers getting more and more pressure from brands and retailers to optimize CO2 footprint and water consumption on their products without increasing their price level. From technology standpoint it could be mostly achieved only by integrating cost intensive, completely new machines with new, sometimes unknown technology. The total investment and running costs have to lead to a price increase which is not accepted in the actual market conditions. What if there is a possibility to upgrade your existing continuous dyeing or finishing line to reduce strongly your CO2 footprint, your water consumption and raise your productivity with a much smaller invest?“

No shortage of chances in China and other Asian markets

The VDMA team in Shanghai is staffed again with colleagues from the VDMA headquarters in Germany as well as from VDMA China. With these joined forces, the team is well prepared to support the exhibiting member companies on site.

Dr. Harald Weber, Managing Director VDMA Textile Machinery Association, summarised: “Although facing a difficult market situation, this year’s ITMA ASIA is an essential showcase for the member companies of the VDMA Textile Machinery Association. There is definitely no shortage of chances and opportunities in China and other Asian markets. The exhibiting members will demonstrate their smart technologies that can pave the way to a green textile production and are looking forward to welcoming numerous visitors from various countries to their booths in Shanghai.”

Posted: October 14, 2024

Source: The German Textile Machinery Association (VDMA)

Q-Lab, a supplier of weathering and corrosion equipment and outdoor exposure testing, is pleased to announce the launch of its newly redesigned website at www.Q-Lab.com.

Q-Lab, a supplier of weathering and corrosion equipment and outdoor exposure testing, is pleased to announce the launch of its newly redesigned website at www.Q-Lab.com.