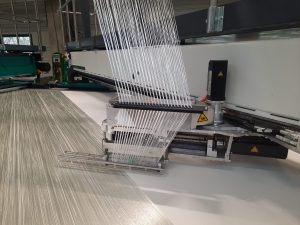

EMIGSVILLE, PA— November 18, 2024 — Herculite Products Inc., an innovator and manufacturer of high-performance and custom fabrics, proudly announces a significant safety milestone: two consecutive years with zero loss-time incidents (LTI). This achievement underscores our associates’ unwavering commitment to safety, operational excellence, and the well-being of their teammates.

EMIGSVILLE, PA— November 18, 2024 — Herculite Products Inc., an innovator and manufacturer of high-performance and custom fabrics, proudly announces a significant safety milestone: two consecutive years with zero loss-time incidents (LTI). This achievement underscores our associates’ unwavering commitment to safety, operational excellence, and the well-being of their teammates.

Safety is a core value at Herculite, and this milestone reflects the dedication and diligence of every associate in upholding the company’s high safety standards. Reaching two years without a single LTI is an excellent accomplishment, demonstrating Herculite associates’ commitment to following safety protocols, participating in regular training, and maintaining constant vigilance while on the job.

Herculite President and CEO Peter McKernan said: “At Herculite, our goal to be world-class starts with Safety. Our Associate-driven culture is empowered to work safely and ensure our fellow associates share the same level of commitment to safety. I am extremely proud of all our Associates for reaching this milestone.”

Herculite Vice President of Operations Gary Harrelson said: “We are all excited about the positive results we are seeing with our Safety Culture. All associates take ownership in our Safety Journey and remain vigilant in ensuring that we foster a work environment that is safe for everyone.”

Over the past two years, Herculite has invested in various safety initiatives, including:

- Enhanced Training Programs: Regular, comprehensive safety training for employees and management.

- Upgraded Safety Equipment: State-of-the-art tools and personal protective equipment to ensure maximum on-site safety.

- Robust Safety Protocols: Continuous review and improvement of standard operating procedures to prevent incidents before they happen.

- Employee Wellness Programs: Support programs that ensure all employees’ mental and physical health.

Herculite associates recognize that maintaining a safe workplace is an ongoing process, and they remain committed to upholding and exceeding industry safety standards. As Herculite celebrates this milestone, we seek ways to continue this track record of safety excellence. Our associate-led safety team, Safe-Pack, will continue to foster a proactive safety culture by empowering fellow teammates to prioritize health and safety to achieve our goal of setting new benchmarks in the industry and contributing positively to the communities in which Herculite operates.

Posted: November 18, 2024

Source: Herculite Products Inc.