CHICAGO — June 9, 2025 — The 35th annual Best of NeoCon Awards kicked off NeoCon 2025 this morning with a high-energy ceremony at THE MART, spotlighting the most forward-thinking products transforming the future of commercial interiors. A cornerstone of NeoCon since 1990, the iconic program celebrates exceptional solutions spanning workplace, healthcare, education, retail, and hospitality. This year, 96 awards were given to exhibitors for products across more than 40 categories, with honors awarded for Gold, Silver, Innovation, Sustainability, and Business Impact. The program’s top distinction, Best of Competition, was awarded to HALCON for its ASTORIA collection of conference and mobile communal tables.

CHICAGO — June 9, 2025 — The 35th annual Best of NeoCon Awards kicked off NeoCon 2025 this morning with a high-energy ceremony at THE MART, spotlighting the most forward-thinking products transforming the future of commercial interiors. A cornerstone of NeoCon since 1990, the iconic program celebrates exceptional solutions spanning workplace, healthcare, education, retail, and hospitality. This year, 96 awards were given to exhibitors for products across more than 40 categories, with honors awarded for Gold, Silver, Innovation, Sustainability, and Business Impact. The program’s top distinction, Best of Competition, was awarded to HALCON for its ASTORIA collection of conference and mobile communal tables.

A multidisciplinary jury of 42 architects, designers, specifiers, enterprise clients, and facility managers—including leaders from Gensler, Corgan, CannonDesign, Marmon Mok, Shepley Bulfinch, Aflac, and Walgreens—convened on-site at THE MART to evaluate submissions throughout the NeoCon show floors. An additional panel of eight business media professionals and two facility managers determined the Business Impact Awards. See the full jury list here: https://neocon.com/awards/best-of-neocon#jury

“The jurors were incredibly thoughtful and rigorous in their evaluations this year,” says Eileen McMorrow, Director of Best of NeoCon. “The winning products aren’t just keeping pace with industry trends—they’re actively driving critical design movements, from circularity and neuro-inclusive thinking to the integration of AI and advanced material innovation. We saw manufacturers embrace empathy, rethink flexibility, and experiment with form and function, addressing the evolving ways people live, work, heal, learn, and connect now.”

The Best of Competition-winning ASTORIA collection by HALCON is tailored for the modern workplace and crafted to create elevated spaces for connection, conversation, and community. Jurors praised the well-appointed assortment for its exceptional design and everyday usability, highlighting its sculptural bases, refined materials, and thoughtfully concealed rolling casters. With flexible configurations, integrated technology options, and meticulous attention to detail, ASTORIA offers a compelling solution for today’s dynamic environments.

“Elegance is the key word when it comes to ASTORIA. It makes the capabilities seem too good to be true. Here, you will not be sacrificing design for functionality,” notes the jury. The line was also recognized for Gold Awards in the Collections for Collaboration, Tables: Café, and Tables: Conference categories. Best of Competition finalists included Davis Furniture’s JeLa Guest, Extremis’s Panigiri, Isomi’s Knit One, and Keilhauer’s Unifi.

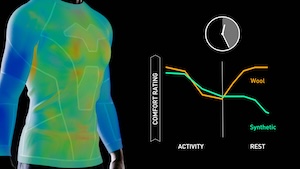

Other manufacturers, such as Arktura, DARRAN, Extremis, Formica Corporation, Keilhauer, Mizetto, Momentum Textiles & Wallcovering, Safco, and Shaw Contract earned Innovation Awards for products bringing bold new ideas to market through breakthrough technologies, novel features, or reimagined approaches to familiar challenges.

Products from Andreu World, HÅG, Haworth, Isomi, KFI Studios, Momentum Textiles & Wallcovering, Nienkämper, Patcraft, and The Good Plastic Company were recognized with Sustainability Awards, reflecting a strong commitment to environmental responsibility through the use of recyclable or biodegradable components, eco-conscious manufacturing practices, and alignment with industry certifications and standards.

Returning for the fourth year, the Business Impact Awards recognized design solutions driving organizational performance through smarter workflows, cost savings, space optimization, and other strategic outcomes. Judged by a panel of business journalists from Bloomberg, Newsweek, Vogue Business, Forbes and Morning Brew, among other notable publications—alongside seasoned facility managers from Northwestern Mutual and Aflac—the awards were based on first-hand product evaluations conducted on-site at THE MART. Each product was thoroughly vetted on criteria including adaptability, sustainability alignment, technology integration, productivity, wellness and user experience, and contribution to the bottom line.

This year, 26 Business Impact Award finalists were selected, with 10 award recipients ultimately honored across categories ranging from furnishings and materials to architectural systems and integrated technologies. The Business Impact Winners for 2025 were Clarus’ Lynk, CMS Electracom’s Freedom FR210 Series, Framery’s One Lounge, Haworth’s Closed-Loop Manufactured Fern, Keilhauer’s Unifi, Kwalu’s Ellie Recliner + Sleeper Sofa Collection, Momentum Textiles & Wallcovering’s Renaturation, Safco/Onsemble’s Modix System, Schiavello’s Focus Quiet Room Plus, and Visplay’s Omnio Office.

Competition-wide, the most awarded companies were Andreu World (9), Keilhauer (6), Davis Furniture (4), Patcraft (4), and Schiavello (5)—each earning accolades across multiple product categories.

New for the 35th edition, Best of NeoCon has introduced the People’s Choice Awards, allowing the design community at large to weigh in on its favorite Best of NeoCon–winning products on-site and online. People’s Choice voting is open now through Tuesday, June 10, at 5:00 p.m. CDT, with the top five winners to be announced on Wednesday, June 11. Show attendees can vote by scanning QR codes on award-winning products throughout the building; others can vote online via the Winners Gallery: https://bestofneocon.secure-platform.com/a/gallery?roundId=17

The Best of NeoCon Awards remain a powerful snapshot of an industry in motion—where materials, systems, and furnishings are recognized in service of both people and the planet. View the full list of 2025 winners here: https://neocon.com/awards/best-of-neocon

Posted: June 9, 2025

Source: Merchandise Mart Properties Inc. – Novità Communications