HALIFAX, England — July 12, 2021 — James Heal, part of the PPT Group of companies, announced today the launch of its new microsite located at performance.james-heal.co.uk. The new website has been created as a dedicated resource on performance testing, which the test equipment manufacturer describes as, “testing technical textiles and fabrics, which have technical and functional benefits such as comfort and safety, across a wide spectrum of applications — from PPE, to bedding, outerwear to sports wear”.

HALIFAX, England — July 12, 2021 — James Heal, part of the PPT Group of companies, announced today the launch of its new microsite located at performance.james-heal.co.uk. The new website has been created as a dedicated resource on performance testing, which the test equipment manufacturer describes as, “testing technical textiles and fabrics, which have technical and functional benefits such as comfort and safety, across a wide spectrum of applications — from PPE, to bedding, outerwear to sports wear”.

James Heal, has developed the new microsite to showcase its range of Performance Testing instruments, whilst also providing useful resources — such as articles, videos and guides — on how to test performance textiles.

The microsite was developed separately to the main company website because, says PPT Group Marketing Manager Jenny Montgomery: “As a design and innovation leader in textile testing, it’s important for us to make information regarding our instruments and information resources easily accessible for our current and prospective customers. We decided to develop something outside of our primary website, to focus on this niche area of textile testing, and add value through an intuitive interface and personalized content, providing an easier way to learn about performance testing; why it’s needed, and to browse information based on specific applications.”

The testing equipment manufacturer says the new microsite will provide the most accurate, up-to-date information and share knowledge and expertise in the field of performance testing, across a wide spectrum of applications, including:

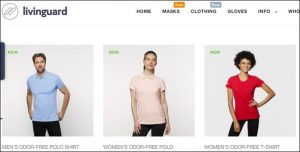

- Sportswear and Activewear: clothing and footwear worn for sport or exercise, such as tracksuits, shorts, t-shirts and polo shirts.

- Outdoor wear: includes garments that require a comfort/safety benefit such as snowsuits, ski clothing, and hiking/trekking clothing.

- Nonwovens: from disposable consumer products such as wipes and sanitary products, to medical gowns, face masks, home decor, clothing and construction supplies.

- Military apparel: textiles for military uniforms face a complex set of challenges when it comes to performance: they must offer maximum endurance, comfort, and protection.

- Bedding and mattresses: include materials and products that are normally used on top of a mattress, such as mattress covers, sheets, blankets, quilts and pillows.

- PPE: includes garments and face/body coverings used in a range of sectors; from medical, to construction, military to workwear.

- Medical textiles: encompasses medical and hygiene applications, including those for surgical, orthopaedic, and dental uses; from personal protective equipment (PPE), bandage and dressing materials through to implantable prosthetics.

- Tents & awnings: used for a variety of purposes – from domestic camping trips, to marquees for events, and even military-grade tents and temporary shelters.

Why performance testing is important

Continuous innovation and consumer demand in the sectors mentioned above, is driving the need for textile testing more than ever, and testing during development enables manufacturers and brands to better understand the capabilities of the fabric to inform their R&D and design decisions.

Compared with mainstream fashion garments, performance fabrics have technical or functional benefits, for comfort and/or safety. The rise in performance fabrics means there is a need for new and improved technology for testing, because the functionality of performance wear and technical textiles must be qualified by evidence.

For example, in sports performance clothing, the term ‘protection’ has expanded to embrace:

- fit and comfort;

- abrasion resistance;

- insulation;

- tear strength;

- sweat wicking;

- waterproofing; and

- antibacterial and anti-UV properties.

“Therefore, it’s crucial for sportswear brands to validate and substantiate claims on performance and functionality — for example, moisture control and breathability”, explained Montgomery.

The James Heal Performance Testing range has been built for a range of applications including moisture management, dry rate testing, water repellency and wet abrasion. James Heal emphasises that their textiles performance testing instruments are designed to give confidence in their results, whether you are a manufacturer, retailer, or brand.

Posted July 13, 2021

Source: James Heal