BOBINGEN, Germany — July 6, 2021 — After a challenging 2020 for Trevira CS®, a year in which the coronavirus crisis put pressure on the contract market, in particular on the hotel and event sector, and also on the cruise shipping industry, the market is starting to show some signs of improvement. Numerous new developments, in particular by Trevira CS Club members, are showing the way forward in the “post-Covid” era and are seizing upon the trends that have emerged since the crisis began.

Trevira CS Club members 2021

In 2021, Trevira continues with the successful Trevira CS Club concept. The 2020 Gold and Silver members saw their status carried over to 2021. Accordingly, the Trevira CS Club 2021 consists of the following members:

Trevira CS Gold members

Yarn Producers: Fil Man Made Group S.r.l., Ilcat by Lei Tsu s.r.l., Selvafil S.A., Spinnerei Lampertsmühle GmbH, Torcitura Fibre Sintetiche S.p.A., Torcitura Padana S.p.A.

Fabric Manufacturers: Dina Vanelli Tekstil San. Ve Tic. A.S., Engelbert E. Stieger AG, FIDIVI Tessitura Vergnano S.p.A., Gabriel A/S, Gaudium B.V., Gebrüder Munzert GmbH & Co. KG, Lodetex S.p.A., P.I.F. S.A., PUGI R.G. S.R.L., Schmitz Textiles GmbH + Co. KG, SVENSSON, Tessitura Mario Ghioldi & C. s.r.l, Verotex AG, Vescom Textiles GmbH

Textile Editors / Wholesalers: Artimo Textiles B.V., Création Baumann AG, Coulisse B.V., Gerriets GmbH, JAB Josef Anstoetz KG, Kvadrat A/S, Panaz Ltd, Rubelli S.p.A.

Trevira CS Silver members

Yarn Producers: Hoftex GmbH, Tintoria Sala s.r.l., Vlnap a.s.

Fabric Manufacturers: Alois Tessitura Serica s.r.l., Ambience Home Textiles, Benaud Créations S.A., Chamatex SAS, Delius GmbH, DHJ Weisters Ltd, E. Boselli & C. S.p.A., G-TEX S.r.l., Gebrüder Colsman GmbH & Co. KG, Gustavo de Negri & ZA. MA. s.r.l., Hohmann GmbH & Co. KG, Mario Sirtori S.p.A., Mattes & Ammann GmbH & Co. KG, Morton Young and Borland Ltd, Pongs Technical Textiles GmbH, Regina Baumann GmbH, Rothböck Textiles GmbH, Spandauer Velours GmbH & Co. KG, Stotz & Co. AG, Swisstulle AG, TF Création S.A.S., van Clewe Sun Protection GmbH, Velener Textil GmbH, Wintex S.r.l., Yanar Tekstil

Textile Editors / Wholesaler: 4Spaces Textiles, Créations Métaphores, Kinnasand GmbH, Lelièvre S.A.S., Mottura S.p.A., Sahco GmbH, Skopos Fabrics Ltd., SoFarSoNear S.n.c., Tapicerías Gancedo S.A., Zimmer + Rohde GmbH

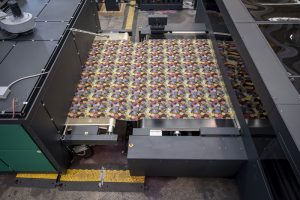

New Trevira CS collections: innovative, functional, sustainable … and flame retardant

Although the coronavirus pandemic had a negative effect on individual business sectors, it also has the potential to open up new market opportunities for flame retardant Trevira CS fabrics in the long run. The increase in people working from home and the longer and more frequent stay within one’s own home have led to a change in perspective in terms of the relevance of interior design. The design of the living space has undergone a revaluation so that end users now possibly attach more importance to a nicer decor.

Sustainability, durability, high quality, and the desire for safe products that contain little to no harmful substances are often the defining criteria for selecting a new textile interior. The colour range of the new Trevira CS developments is directed specifically towards this trend and often comes across as discreet and close to nature. After Trevira CS products have found their way more and more into private homes, the new Trevira CS collections include numerous attractive textiles not only for the contract sector but also for the residential sector.

Posted September 8, 2021

Source: Trevira GmbH