VALENCIA, Spain — March 20, 2024 — Coinciding with World Water Day celebrations and under the slogan “Water, a shared responsibility,” the eco-efficient textile technology company, Jeanologia, calls on this productive sector, appealing for a real change, away from greenwashing and towards concrete and collective action.

VALENCIA, Spain — March 20, 2024 — Coinciding with World Water Day celebrations and under the slogan “Water, a shared responsibility,” the eco-efficient textile technology company, Jeanologia, calls on this productive sector, appealing for a real change, away from greenwashing and towards concrete and collective action.

Three decades ago, Jeanologia began its journey swimming against the current in an ocean of skepticism within one of the world’s most polluting productive sectors: the textile industry. It became a pioneer and revolutionized the industry by demonstrating that fashion could be produced by significantly reducing its environmental impact and without compromising quality or profitability, relying on technology to achieve this.

Since its foundation, Jeanologia has led sustainable change in the textile industry, thanks to its innovative technologies, which have drastically reduced water consumption and returned the minimal amount of water used to nature in perfect condition, as well as minimizing the use of chemicals and energy and eliminating harmful emissions and discharges.

New environmental record

In 2023, Jeanologia set a record in its environmental P&L statement, measuring in cubic meters the contaminated water that is no longer discharged into rivers and seas, as well as the reduction of toxic emissions, thanks to its technological advances and services.

The technologies developed by Jeanologia have saved the planet 20,265,581 cubic meters of contaminated water in 2003, equivalent to the consumption of a city the size of Brussels or more than 1,200,000 Olympic pools. Additionally, 97,895,304 kilograms of CO2 emissions were reduced, equivalent to the carbon absorbed by a forest of 9,800,000 trees.

The key to success lies in the integration of eco-efficient technologies in all stages of production, from fabric to garment finishing. In this way, water consumption in the garment finishing process has been drastically reduced, from 70 liters to just 1 liter per garment. These technologies have also significantly reduced the use of chemicals and energy, as well as emissions and harmful discharges derived from textile production. All this without compromising quality or design.

Furthermore, Jeanologia’s eco-efficient technologies include the H2 ZERO effluent recycling plant, a key component of their Mission Zero initiative. This innovative system is able to recover 95% of water used in the production process. It plays a vital role in creating a closed-loop system, ensuring minimal water wastage and contributing to a sustainable ecosystem for brands and their suppliers. Thanks to H2 ZERO, water is treated without chemicals, maintaining optimal conditions for reuse, aligning with Jeanologia’s commitment to environmental responsibility and resource conservation.

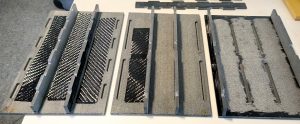

Additionally, Jeanologia’s Air Fiber Washer project focuses on removing microfibers from the garment finishing process, thereby contributing to the preservation of the seas and preventing these microfibers from contaminating marine ecosystems.

Jeanologia also recognizes the importance of measurement and transparency in environmental impact. For this reason, over 10 years ago, it made available to the industry the Environmental Impact Measurement (EIM) software, which today more than 100 brands and 400 laundries worldwide use to measure and improve their collections, avoiding greenwashing and being completely transparent.

An invitation towards a more sustainable water management

On World Water Day, Jeanologia reiterates its commitment to continue leading its Mission Zero: achieving total dehydration and detoxification of the textile industry. A challenge turned into an urgency following UNESCO’s warning that we face an imminent global water crisis, with between 2,000 and 3,000 million people suffering from water scarcity worldwide, water demand far exceeding supply capacity in many parts of the world, and the environmental impacts of its overexploitation becoming increasingly evident.

In this context, the Spanish technology company urges adopting a collective commitment. As Jeanologia’s CEO and founder Enrique Silla states, “we are an impact company focusing on water.” Thus, its goal is to reduce the consumption of this resource throughout the textile process to the bare minimum, eliminate 100% of the waste generated in the manufacturing and finishing of garments, and preserve the seas, eliminating any possible microfiber from the production process to prevent it from ending up in the oceans.

Jeanologia has managed to transform the global textile industry, and today its involvement goes further. Although acknowledging that the world has awakened to the urgency of sustainability, Jeanologia claims that there is still a long way to go. Individual awareness and isolated actions are not enough. Water scarcity is a global challenge that requires comprehensive and collaborative solutions involving governments, institutions, companies, and individuals. “The global context urges us to unite and accelerate action, and on a date as significant as World Water Day, we want to offer our example as inspiration and invite other companies to join our Mission Zero,” claims Enrique Silla.

Jeanologia: over 25 years transofming the textile industry

Since 1994, Jeanologia’s mission has been to create an ethical, sustainable, and eco-efficient textile industry. The company collaborates closely with brands, retailers, and their suppliers on their transformative journey, offering disruptive technologies, innovative software, and a new operating model.

In 2024, Jeanologia celebrates the 25th anniversary of its pioneering laser technology, launched in 1999, which revolutionized denim finishing, replacing harmful practices and eliminating the use of hazardous substances. With the same purpose, Jeanologia now faces the challenge of reducing the environmental impact of the garment dyeing process—one of the most polluting in the industry—through its revolutionary ColorBox technology.

Posted: March 21, 2024

Source: Jeanologia

NEW YORK CITY — March 21, 2024 — UNTUCKit, creator of Shirts Designed to be Worn Untucked, is excited to announce the opening of at least 14 new retail stores by the end of 2024. The first seven locations will open by this May across California, Georgia, Florida, New Jersey, and New York. Another seven locations are in advanced lease negotiations. Each new location will offer the UNTUCKit men’s collection and show the brand’s continued commitment to expanding its retail portfolio. When completed, these additions will put UNTUCKit’s store count just shy of 100 globally.

NEW YORK CITY — March 21, 2024 — UNTUCKit, creator of Shirts Designed to be Worn Untucked, is excited to announce the opening of at least 14 new retail stores by the end of 2024. The first seven locations will open by this May across California, Georgia, Florida, New Jersey, and New York. Another seven locations are in advanced lease negotiations. Each new location will offer the UNTUCKit men’s collection and show the brand’s continued commitment to expanding its retail portfolio. When completed, these additions will put UNTUCKit’s store count just shy of 100 globally.