WILMINGTON, Del., April 29, 2002 DuPont TextilesandInteriors (DTI) today announced actions that

will advance its progress toward becoming a more competitive integrated enterprise. As part of its

drive to capitalize on the strength of its newly combined businesses in response to rapidly

accelerating industry structural changes, DTI plans to reduce more than 2,000 employees worldwide,

or 10 percent of its global work force. More than two-thirds of the reductions are in manufacturing

facilities and offices in the United States, with most of the balance in Europe. In the U.S., DTI

plans to shut down its Terathane® PTMEG manufacturing unit at Niagara Falls, N.Y., and less

competitive portions of the spandex operation at Waynesboro, Va. “These are difficult but necessary

actions to position DTI for success in a highly competitive and rapidly consolidating industry,”

said Richard R. Goodmanson, DuPont executive vice president and chief operating officer, who is

leading DTI. “We must act quickly and decisively to match our resources with current market

realities. We are committed to doing what it takes to capture market opportunities while serving

our customers with speed and flexibility.” “We do not anticipate a negative impact to our revenue

streams as a result of these restructuring actions,” Goodmanson added. “We will support our current

revenue base from more competitive facilities. We are primed to grow revenues by capitalizing on

our strong global market access, key branded platforms and a robust innovation pipeline targeting

the global apparel, interior and textile markets.” DuPont expects to achieve annual pre-tax cost

savings of about $120 million as a result of these actions, realizing about 30% in 2002 and

substantially all in 2003. The company expects to take a one-time second quarter charge of 12-16

cents per share, with about two-thirds due to employee separation costs, and the balance for asset

shutdowns. Since plans are still being finalized, the actual one-time charge to earnings will not

be available until the end of the second quarter. DuPont announced in February that it planned to

create DTI as a new wholly owned subsidiary and separate it from DuPont by year-end 2003, market

conditions permitting. The company is evaluating a range of separation options, including an

Initial Public Offering. DTI includes the nylon fibers, polyester fibers, Lycra® brand fiber and

spandex businesses, plus their intermediates and joint ventures. “We recognize that this is a

difficult time for all employees,” Goodmanson said. “We appreciate the contributions of our

employees who will be leaving and we will treat everyone whether they are leaving or staying —

with dignity and respect.” Current plans call for more than half of the affected employees to leave

DuPont by July 31. They can take advantage of transition packages available in their country or

region. For example, U.S. employees leaving DuPont will receive a severance package providing them

with career transition payments based on length of service, as well as a range of health and dental

benefits and educational assistance. DuPont TextilesandInteriors is the largest integrated textile

fiber and interiors business in the world, with approximate annual revenue of $6.5 billion and

operating in 50 countries. Headquartered in Wilmington, Del., DTI is comprised of two units, each

with subgroups: Textiles and Interiors including apparel, home, industrial and flooring; and

Intermediates including nylon, Terathane® PTMEG and polyester intermediates, specialties and joint

ventures. DuPont TextilesandInteriors has a powerful portfolio of the best-known, worldwide brands

and trademarks of DuPont including: Lycra®, Stainmaster®, Coolmax®, Thermolite®, Supplex®, Antron®,

Cordura®, Tactel®, Dacron® and Micromattique.During 2002, DuPont is celebrating its 200th year of

scientific achievement and innovation providing products and services that improve the lives of

people everywhere. Based in Wilmington, Del., DuPont delivers science-based solutions for markets

that make a difference in peoples lives in food and nutrition; health care; apparel; home and

construction; electronics; and transportation.Forward-Looking Statements: This news release

contains forward-looking statements based on managements current expectations, estimates and

projections. All statements that address expectations or projections about the future, including

statements about the companys strategy for growth, product development, market position, expected

expenditures and financial results are forward-looking statements. Some of the forward-looking

statements may be identified by words like “expects,” “anticipates,” “plans,” “intends,”

“projects,” “indicates,” and similar expressions. These statements are not guarantees of future

performance and involve a number of risks, uncertainties and assumptions. Many factors, including

those discussed more fully elsewhere in this release and in documents filed with the Securities and

Exchange Commission by DuPont, particularly its latest annual report on Form 10-K and quarterly

report on Form 10-Q, as well as others, could cause results to differ materially from those stated.

These factors include, but are not limited to changes in the laws, regulations, policies and

economic conditions, including inflation, interest and foreign currency exchange rates, of

countries in which the company does business; competitive pressures; successful integration of

structural changes, including restructuring plans, acquisitions, divestitures and alliances; cost

of raw materials, research and development of new products, including regulatory approval and

market acceptance; and seasonality of sales of agricultural products.

DuPont TextilesandInteriors Takes Actions To Increase Competitiveness

Pillowtex Fills Positions At Kannapolis Facilities

Pillowtex Fills PositionsAt Kannapolis FacilitiesPillowtex Corp. has begun to fill 200 positions at

its facilities in Kannapolis, N.C., as a result of the companys decision to relocate operations

from Columbus, Ga., and Phenix City, Ala., to Kannapolis. The consolidation is an attempt to

improve efficiencies throughout manufacturing operations.Pillowtex hopes to rehire workers laid off

in previous restructuring efforts affecting Plant One and Plant Four in Kannapolis.We are glad to

be able to rehire some of the people who were impacted by layoffs in Kannapolis. However, we

realize that while the news of 200 positions in Kannapolis is positive for our employee base in

this community, our employees in Phenix City and Columbus are facing the loss of jobs, which is

always a difficult time, said Allen Oakley, executive vice president of manufacturing

operations.Since filing for Chapter 11 reorganization in November 2000, Pillowtex has taken steps

to eliminate manufacturing overcapacity and maximize efficiency by consolidating and relocating

some of its operations.

April 2002

X-Rite Presents New Quality Assurance Solution

X-Rite Presents NewQuality Assurance SolutionX-Rite Inc., Grandville, Mich., has redesigned its

color formulation and quality assurance solutions in the new X-RiteColor® Master, an easy-to-use

Windows-based core software platform. The software is available in five configurations including

QA-Master I and II for color quality assurance; and Formulation-Master I, II and III for color

formulation and quality assurance. It is networkable and scalable, has an innovative database

structure and can span a variety of applications. Standard features include opacity adjustment and

waste reuse, which provide savings of time and resources, according to X-Rite.

April 2002

A Hybrid Industry

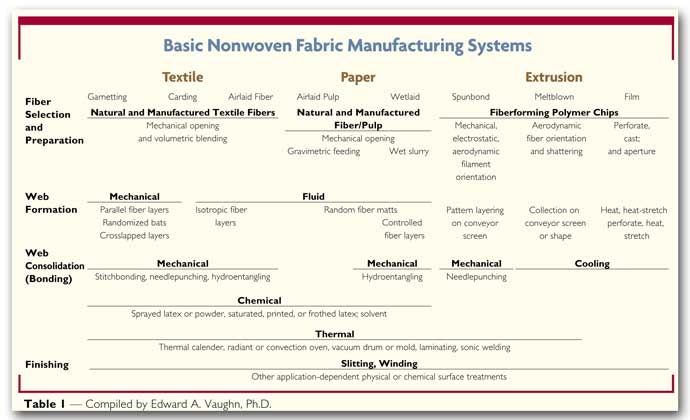

By Richard G. Mansfield, Technical Editor A Hybrid IndustryHybrid nonwovens breed innovative products and solutions. Accelerated growth in nonwoven technologies and the use of nonwovens may look revolutionary to people not familiar with the history of the industry, but this growth is actually based more on evolution than revolution. Edward A. Vaughn, Ph.D., professor of textiles at Clemson University, was very early in recognizing nonwovens as a hybrid technology and its long-term growth potential as a business. In addition to his teaching activities in nonwovens, Vaughn created the Clemson Nonwovens Fabric Forum, a week-long course that has helped train thousands of people in the industry over the last 32 years.Vaughn created a table, Basic Nonwoven Manufacturing Systems, which shows how nonwoven manufacturing has become a hybrid of textile, paper and extrusion technologies (See Table 1).

Early U.S. Activity In NonwovensOne of the earliest companies in the nonwovens business was Chicopee, then a division of the JohnsonandJohnson Co. In the mid-1940s, Chicopee developed its Masslinn nonwovens. Unlike many of the other early nonwoven producers, Chicopee was working with good-quality rayon staple fibers as well as cotton. Kendall Mills was another early entrant into the U.S. nonwovens business. Nonwovens product development activities continued to grow in the United States into the 1950s. Much of the early work with nonwovens was done by cotton mills, which were seeking to upgrade cotton waste into salable products such as furniture stuffing and wipes. Some of the mills then working with nonwoven technology were Avondale Mills, Callaway Mills, Dan River and WestPoint Manufacturing.The mid-1950s marked the successful development and marketing of Chicopees Handi-Wipes, one of the earliest identifiable nonwoven consumer products. During this time, Pellon Corp., owned by Freudenberg Nonwovens Group of Germany, became an important U.S. producer of nonwovens, specializing in inner linings and interfacings for the apparel trades. Up until the 1960s, the major technology for nonwovens was based on drylaid technology. The 1960s, however, saw the introduction of spunbonded technology and early activity on meltblown nonwovens. Needlepunch and wetlaid nonwoven technology and products also came into greater use. By the 1970s, the establishment of a trade association for nonwovens, the Association for the Nonwoven Fabrics Industry (INDA), provided a focal point for nonwovens as useful and distinct materials differentiated from conventional textile materials.The 1980s was a decade of increasing growth in nonwovens activity throughout the world, particularly in spunbonded and meltblown products. Factors influencing spunbonded and meltblown growth included the expiration of patents, which led to the development of turnkey plants from companies like Germany-based Reifenher, as well as lower-cost and higher-quality polyolefin and polyester resins.The 1990s marked the era of widespread acceptance of nonwovens as performance and problem-solving materials for industries as diverse as civil engineering and healthcare. Many of the products that came into use during this time were based on composites made by combining different types of nonwovens and/or nonwovens with other materials, such as films and foams. Some of these products and the companies that produce them are discussed in the ensuing pages. Composite Nonwovens In Geosynthetic ProductsIn the early 1970s, interest developed in using textile and related structures in construction and civil engineering applications, and the term geotextiles was coined for these products. Dr. Robert Koerner of the Drexel Institute of Technology describes geotextiles as products produced by assembling fibers into a flexible fabric by weaving, knitting or using nonwoven techniques to provide a porous water flow across and within their manufactured plane. Geotextiles always perform one of the following discrete functions: separation; reinforcement; filtration; drainage; or moisture barrier (when coated or impregnated).The term geotextiles is still used to describe these products, but a broader category of products is now encompassed by the term geosynthetics. One of the earliest fabrics used in civil engineering applications was woven from polypropylene monofilament yarns. Later, spunbonded and needlepunched polypropylene and polyester fabrics gained acceptance in geotextiles. The Geosynthetics Materials Association (GMA) represents all segments of the geosynthetic industry, including manufacturers as well as companies that test or supply materials and services to the industry. GMA is based in Roseville, Minn. As the use of geosynthetics grew, a number of composite fabrics were introduced to help solve problems in civil engineering and building construction. The Netherlands-based Enka, now a member of the Acordis group, which includes the Colbond Geosynthetics Group, introduced Enkadrain®, a foundation drainage system for vertical and horizontal use, in the mid-1970s. Enkadrain consists of a drainage core made up of highly compression-resistant, fused, entangled nylon monofilaments and a geotextile fabric bonded to one side or fully encapsulating the core.

At the Las Vegas Paris Hotel, Colbond Inc.’s Enkadrain® geosynthetic drainage system was installed in a plaza deck. Photograph courtesy of Colbond Inc. Enkadrain works by relieving hydrostatic pressure from backfills abutting below-grade structures. It provides a lightweight alternative to traditional drainage materials such as gravel or sand blankets. The geotextile fabric allows water to seep into the core, while it holds back the adjacent soil and helps develop a natural soil filter where geotextile and soil meet. Water that reaches the resilient polymer core is conveyed to a perforated pipe, weep hole, or other discharge system. Major applications for Enkadrain include foundation and retaining walls, plaza decks, bridge abutments and planters. Enkadrain is lightweight and includes such features as the following:high discharge capacity;protection of waterproof coatings from damage during backfilling;formulation of an insulating layer between wall and soil;prevention of silting up of the collector drain;installation ease with negligible waste;use under all weather conditions, even when freezing;ease of cutting with a sharp knife or scissors; andresistance to rot and soil chemicals. Geosynthetic Clay LinersA geomembrane is a material used as a containment device for landfills, or for forming holding ponds to retain solid and liquid hazardous materials and prevent them from migrating and contaminating groundwater and streams.

CETCO Lining Technologies manufactures geosynthetic clay liners, which protect geomembranes in landfills. Geomembranes are made from both reinforced and nonreinforced polymeric materials, including linear low-density polyethylene, high-density polyethylene, ethylene interpolymer alloys, chlorinated polyethylene, chlorosulfonated polyethylene, ethylene propylene diene monomer, polyvinyl chloride, polyurethane and elastomeric bitumen. The choice of the membrane material depends upon soil conditions and the properties of the materials that must be contained. The purpose of the geosynthetic clay liner (GCL) is to protect the geomembrane in case of damage to prevent leakage. The GCL is prefabricated and made by encapsulating bentonite clay between two or more layers of geotextiles, or by bonding the clay to one side of a geomembrane such as a sheet of high-density polyethylene. The geotextile-supported fabrics hold the clay in place by soluble adhesives or I-ties, by needlepunching that interlocks the fibers and locks in the clay, or by stitching thread to hold the clay between two fabric layers.The bentonite clay is a natural inorganic material with the ability to decrease hydraulic conductivity (it swells when it becomes wet and provides a sealing action). Bentonite is mined in Wyoming and other western states. It was formed through the reaction of volcanic ash and salt water over millions of years. Other major uses for bentonite are in cat litter and in drilling muds for the petroleum industry. A major supplier of the GCL product is CETCO Lining Technologies of Arlington Heights, Ill. Kimberly-Clark’s Composite Nonwoven ProductsKimberly-Clark, Dallas, is active in developing products using composite nonwoven technologies. One of the early composites the company produced was Kaycel, a scrim-reinforced tissue laminate for applications such as patient examination gowns, caps and disposable jackets and aprons.In the late 1960s, Kimberly-Clark licensed spunbond technology from Lurgi of Germany and started production of spunbond polypropylene products. Subsequently, the company refined the original process and developed a large body of technology in the field. Later, Kimberly-Clark added meltblown technology and products, and the company has developed and patented technology and products for making composite nonwovens.The spunbond/meltblown/spunbond (SMS) products provide a breathable barrier that holds back fluids and allows air to pass through. Kimberly-Clarks SMS products are used for a wide range of products from automobile car covers to hospital/medical products, including surgical wrap.Surgical sterilization wrap has been one of the companys most successful and profitable composite nonwoven products. The surgical wrap material is used to provide sterilized kits of components used in the surgical operating room. The multilayered SMS surgical wrap allows sterilizing agents such as steam, ethylene oxide, hydrogen peroxide, and gas plasma to penetrate the wrap, yet maintain sterility.Kimberly-Clarks Coform process enables its polypropylene meltblown process to make composites that are useful for soaking up liquids and body fluids in hospitals in applications such as incontinence pads and fenestration areas on surgical drapes. Optional layers of meltblown, spunbond or film also can be laminated to the structure. The products can be converted by die-cutting, slitting, sewing or heat-sealing. Xymid LLCXymid LLC, Newark, Del., was formed October 1, 1998, and is made up of growing businesses that had been started by the DuPont Co. The majority ownership and management of the company is by an individual who had been responsible for the businesses (and others) when with DuPont.Xymid® is based on proprietary technologies not found in traditional wovens, knits or nonwovens. Some of the products are based on processes and products that were developed by DuPonts fibers, nonwovens and composite groups. The versatility of the techniques enables the inclusion of many different fibers into one fabric.Xymid Wearforce fabrics combine bulkable yarns such as Lycra® with polyester for comfort and nylon for durability. Wearforce G fabrics are Wearforce fabrics combined with a high-performance laminate to provide good gripping surface and high wear resistance. The composite fabrics are resin-impregnated for high abrasion resistance and moldability.Xymid LLCs Composite Products include print sleeves, composite tubing and containment sleeves. Print sleeves are made from polymeric materials and used in the flexographic printing industry. Printing plates are mounted onto the polymeric sleeves, which are then mounted onto print cylinders. The sleeve tightly grips the cylinder because of an interference fit between the two components. The sleeves are extremely durable, according to Xymid, and are easily installed or removed from the cylinders via air pressure. Composite tubing is used in the converting industry for lightweight air shafts, anilox rolls and plate cylinders. This product can weigh as little as one-fifth the weight of steel, and the relative stiffness is two to five times that of steel, Xymid claims. This factor results in improved vibration dampening and higher critical speeds, thus allowing equipment to run faster. Xymids containment sleeves are designed to prevent magnet liftoff due to centrifugal forces generated in high-speed permanent magnet electrical motors and generators. The high strength and light weight of this product provides superior performance over conventional metallic materials, according to Xymid. LANX Fabric Systems produces chemical and biological protective fabrics and apparel for military and emergency response applications. LANX Fabric Systems features a family of products that are adsorbent, durable, air-permeable and user-comfortable; and can be fire-resistant as required. The base adsorption technology uses polymerically encapsulated activated carbon for chemical protection.Zyflex LLC Thermal Sportgear® consists of a line of garments using a composite technology that had originally been developed by DuPont. These products are being sold by catalog and on-line, and include thermal shirts, thermal shorts, headbands, neckgaiters and balaclavas.

LANX Fabric Systems produces chemical and biological protective fabrics for military and emergency response applications.April 2002

Glenro Names Three Executives To Upper Management

Paterson, NJ; 04 April 2002 – Glenro Inc. has promoted three of the company’s managers to new

executive management positions. Effective immediately, Thomas Van Denend has been named Vice

President; John Walsh has been promoted to Vice President Sales; and Jim Alimena is now Glenro’s

Vice President Marketing.In his 21-year career at Glenro, Thomas Van Denend has become recognized

as an authority on industrial heat processing technologies. Prior to his new assignment, Van Denend

ran Glenro’s Western sales office, where he was instrumental in new business development as well as

new product and technology launches. In his new role, Van Denend will concentrate on developing and

commercializing new product lines for Glenro, including flatbed laminating systems, advanced

infrared heaters and regenerative thermal oxidizers. Van Denend is also pursuing acquisitions and

developing strategic alliances with companies that serve the same customers as Glenro.John Walsh

has 25 years of manufacturing engineering, industrial engineering and business management

experience in the production of industrial equipment, electronics, outdoor equipment, automotive,

and structural steel components. He has been with Glenro since 1993, excepting a two-year

engagement with Garden Way Inc. as Director of Manufacturing Engineering. Walsh was previously

Plant Manager with Glenro, and he brings extensive experience in the needs of manufacturing to his

new role as Vice President Sales. He directs Glenro’s nationwide network of sales engineers, as

well as developing international sales opportunities.As Vice President Marketing, Jim Alimena is

responsible for creating sales opportunities, building brand awareness, managing Glenro’s marketing

information system, marketing research, advertising and public relations. Alimena is a 22-year

Glenro veteran, during which time he has built a marketing communications team and created an

integrated marketing communications program using electronic and print media. He developed Glenro’s

Internet strategy and web site, ww.glenro.com. Under Alimena’s direction, Glenro’s trade

publication ads have won several readership response and brand awareness awards.The new management

assignments are part of Glenro’s objective to develop an interrelated process among engineering,

marketing and sales to launch new products that meet the needs of customers.Headquartered in

Paterson, New Jersey, Glenro Inc. provides process heating engineering and equipment for industries

such as paper and film converting, nonwovens, technical textiles, insulated wire and tubing. Glenro

equipment includes infrared heaters and ovens, hot air dryers, fume oxidizers and flatbed

laminators.

ASTM Forms New Business Development Unit

ASTM Forms NewBusiness Development UnitWest Conshohocken, Pa.-based ASTM International has formed a

New Business Development Unit to benefit organizations and businesses by making available ASTMs

expertise in the development and distribution of technical information. The new unit facilitates

outsourcing and partnership agreements between ASTM International and its clients, and helps them

develop solutions that enable them to enhance and streamline their businesses.Capabilities of New

Business Development include: provision of a neutral forum to develop standards, guides or best

practices; electronic collaborative authoring, editing and publication; dissemination of global

information; audit-trail management; and multi-format product delivery.Clients are currently

evaluating future projects that involve the outsourcing of ASTMs Interactive Standards Development

Forums Internet-based collaborative standards development software and electronic balloting

systems.

April 2002

Winding Progress

Technology Advancements

TW Special Report Winding Progress

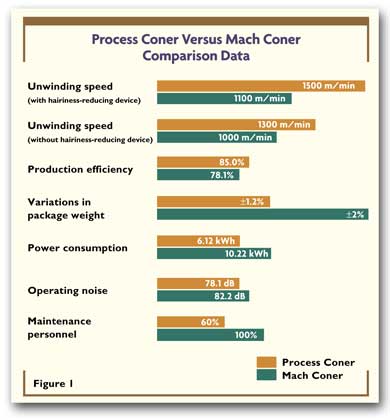

Murata’s new-generation Process Coner improves on features of earlier Mach Coner. It

is essential that the automatic winder, as the final stage of spun yarn production, be capable of

utilizing all of the recent developments in electronic yarn clearers. The automatic winder of the

future will need to continuously monitor and manage the operational status of the machine, as well

as provide on-line and on-time winding. Customers will require continual improvements in the

quality of the yarn. It is to this end that Muratas Muratec Mach Coner, introduced to the

international market in 1979, has recently undergone a full redesign.The new winder (#21C) offers

many innovations and shows significant improvements when compared with the Murata Mach Coner (See

Figure 1):A new winding drum with two distinct pitches on the same drum eliminates ribbon winding

and promotes high-speed unwinding at subsequent processes.A straight yarn path and electronic

tension manager enable high winding speeds with tight controls on package length.Perla-A and

Perla-D devices using compressed air and mechanics respectively reduce yarn hairiness and improve

warping, slashing and weaving operations. Coupled with compact spinning, these devices produce a

yarn having greater added value.An inverter-controlled blower and direct-drive winding drum reduce

power consumption. The blower also reduces operating noise.A kink preventer reduces hard waste,

which is automatically separated from soft waste on the #21C model.

In the event that an abnormal number of faults are detected in one spinning cop, the machine

will automatically remove an increased amount of yarn from the cop before splicing and restarting.

Should the yarn continue to fault, the process will be repeated for a number of attempts. All of

these steps occur without operator intervention. The operation of electronic yarn clearers is

enhanced by the layout of the straight yarn path splicer followed by waxing device in a fully

linear path. Murata has retained the concept of individual unit maintenance during operation and

has reduced the number of mechanical parts, allowing for a reduction in maintenance personnel.The

Process Coner #21C allows ready analysis of data from multiple machines using the Visual On-Demand

System (VOS) on the central control panel. Colored graphic displays are used, facilitating data

feedback and immediate decisions. The new Murata Process Coner offers cutting-edge technology

coupled with practical simplicity for new-generation winding needs.

April 2002

Warp Speed

Weaving PreparationBy Jim Phillips, Executive Editor Warp Speed

Drawing-in, warping and sizing programs save time, decrease cost. Weaving is an

ancient art, dating back more than 7,000 years to when the first baskets were woven from the reeds

that grew along the Nile River in Egypt.And for about as long as mankind has been inserting weft

into warp in some form or fashion, research has been underway to improve the speed of the process,

the quality of the finished product and the weavability of materials.Today, of course, weaving has

evolved into a high-speed, high-technology craft that stresses components and allows little margin

for error. The demands of a global marketplace have put increased pressure on weavers for quick

turnaround, so time to change from one style to another takes on added importance. Much has been

written about the modern weaving machines from such companies as Picanol, Sulzer, Promatech,

Dornier, Toyota, Tsudakoma and others. But an often neglected aspect of technology is the range of

machinery, between spinning and weaving, that enhances yarn properties and creates efficiencies

that allow for faster, better fabric formation. Drawing- And Tying-In

Among the most laborious of all textile processes is the drawing-in and tying-in of warp

yarns. Most plants throughout the world continue to do this process by hand. Stli Corp. of

Spartanburg, a well-known manufacturer of dobbies and jacquard heads, however, has systems

available that automate this process and save significant time and labor.There are so many

advantages to this system, said Don Hunt, the companys manager of textile systems. By hand,

drawing-in is a struggle that requires a lot of labor and a lot of time. But with our systems, such

as the Delta 100 and 110, a single person can draw in up to four warps in eight hours. With two

draw-in trucks and two people, up to eight warps can be drawn-in in a day. The number of warps that

can be drawn-in depends upon the average number of warp threads per warp and the warp material.Adds

Ludovic Petrois, sales technical administrator: The speed of these systems is up to 100 threads per

minute. This adds a tremendous amount of flexibility for the weaver and allows a quick changeover

in order to respond to market demands.The Stli Delta 100 is designed for filament weaving mills

that draw warp threads into the heddles and reeds, but which use no drop wires. The Delta 110 draws

in the warp threads through the drop wires, heddles and reeds in a single operation.For tying-in,

the Stli Topmatic Tying System features reliable formation of up to 600 knots per minute, Petrois

said. Saving Sizing Costs

In an era in which every penny spent for raw materials and labor must be carefully

scrutinized, a number of proactive textile machinery manufacturers have looked for ways to save

their customers money in virtually every step of the manufacturing process. It is to this end that

West Point Foundry and Machine Co., West Point, Ga., has developed its SAS Pre-Wet (PW) Sizing

System. The SAS-PW system uses patented technology to apply atomized water to warp yarns before

they enter the size box. Sizing is, of course, the application of chemicals usually starch, acrylic

esters, polyvinyl alcohol, wax, carboxymethyl cellulose to warp yarns in order to lubricate them in

preparation for weaving, as well as to provide additional strength and smoothness.The West Point

SAS system, according to Scott Warren, general sales manager, is unique in that it precisely

controls the volume of water applied to the warp yarns in order to maintain consistent water wet

pick-up. Also, the system is designed to increase the dwell time between the pre-wet chamber and

size box to maximize water penetration. Warren said studies of pre-wet sizing have shown that size

chemical costs can be reduced by as much as 20 to 50 percent, depending upon yarn styles, without

affecting weaving efficiency. This reduction, he said, is the result of applying water to the warp

yarn before sizing. The water penetrates into the center of the yarn so the sizing material is only

applied to the outer surface of the yarn bundle, reducing the amount of sizing chemicals required

for efficient weaving.Sizing chemicals are the single largest daily cost in this process, Warren

said. The SAS-PW is the lowest-cost pre-wet system available. It has a self-contained control

system and a narrow footprint that will allow it to run on any slasher, regardless of space

limitations or equipment manufacturer. WarpingIn warping, West Points newly designed Model

UWP Warper is designed to accommodate section beam diameters up to 40 inches (1,000 millimeters).

Other features include a pneumatically operated press roll with table doffing, West Points patented

End-Uncrossing Device, and color touch-screen controls. The Model UWP Warper is also equipped with

the companys dust particle collector, which is designed to capture significant amounts of fine dust

particles into the plants air filtration system.Sucker-Muller-Hacoba, Germany, (Symtech,

Spartanburg), offers the Toptronic 2000 sectional warper, which provides fully electronic

determination of the warp table traverse and section positioning. The machine features warping

speeds up to 800 meters per minute (m/min) and beaming speeds up to 300 m/min. As well, the

Toptronic is able to automatically calculate feed from the first meter of the warp, using either

short sample sections or full-length beams.

Benninger Co. Ltd., Switzerland, also represented by Symtech, has the Ben-Direct direct

warper, introduced in 2000, which now has more than 100 installations worldwide. The warper,

according to the company, features exact cylindrical winding, high-precision uncrossed thread

laying, precise length and assured winding density.The Ben-Tronic sectional warper features

universal capability for all staple fiber yarns, as well as textile and technical filaments.

Benninger says the sectional warper guarantees uniform length of all ends, which are wound under

absolutely equal tension.

April 2002

Under Cover

Part 2: Intimate Apparel RoundupBy Virginia S. Borland, New York Correspondent Under Cover

Comfort and performance are hidden assets in some of today’s high-tech intimate apparel

fabrics.

Among the developments prevalent in the intimate apparel market are new yarns that enhance

both appearance and comfort. Greensboro, N.C.-based Unifi, for example, introduced 18 new specialty

yarns last year. Unifi is developing new yarns, modifying and combining existing yarns to provide

innovative products for specific end-uses, said Jay Hertwig, global product development manager.

Many are seeing success in intimate apparel, activewear and swimwear. Novva is a soft, textured

yarn that has the luster of a flat yarn. It is going into seamless, circular and warp knits.Mynx is

a super-soft nylon described as having the strength of a synthetic and the beauty of a natural

fiber. It provides knitted fabrics with a cool, smooth hand, soft drape and subdued luster.Sorbtek

is a breathable, lightweight, easy-care yarn with the ability to move moisture faster and further

than any other yarn on the market today, according to Unifi. It is going into seamless, circular

and warp knits and has had immediate success in activewear.A.M.Y. is a new high-performance

antimicrobial yarn with permanent odor-control properties engineered directly into the

yarn.Recently, Unifi formed a joint venture with Israeli nylon producer Nilit Ltd. Products

developed will come out under the UNF label. One recent introduction is Sensil Arafelle. Arafelle

the Hebrew word for fog is 100-percent nylon 6,6, which can be piece-dyed for tonal, heathered

effects. It has a cotton-like touch and is aimed at lingerie, activewear, swimwear and legwear

markets. Arafelle has been adapted by Sara Lee Hosiery.Kimberley Lewis, marketing manager, Unifi,

sees intimate apparel focused around sheer fabrics with subtle luster and control. There will be

emphasis on comfort achieved through stretch and engineered yarns, she said. FabricsOne of the

fastest-growing knitters catering to the intimate apparel market is McMurray Fabrics, a

family-owned firm with three factories in North Carolina. In 2001, the company purchased the

circular-knit business, as well as the warp-knit elastic fabrics plant in Jamesville, N.C., from

Sara Lees Liberty Division.Kim Williams, director of design and apparel merchandising, said there

will be an inventory correction. She sees a business pickup well before the end of the year.For

bras and panties, Williams reports that a lot of sheer, power-net fabrics are still turning up.

Reporting on the Interfili show in Paris, she said prints and embellishments were some of the

newest lingerie developments. Mesh with lace overlays, metallic and lacquered surfaces, laser-cut

edges, ruffles and jewelry-type applications were all there. A lot of stripes were shown, along

with small, random florals, geometrics that resemble computer printouts, and the look of

denim.Clean piqu#44; small box-patterned jacquards and matte/sheen surfaces are other looks

Williams mentioned. And its all about nylon and microdenier nylon, she said. Colors are brighter.

There are a lot of pinks and blues that look like gum-drop candy colors, and a lot of red and

white.Going forward, Williams mentioned antibacterial and anti-odor fabrics. She sees these going

into socks and activewear, as well as items such as the sports bra. Fabrics In Demand

Debra Cobb, merchandising director, Ge-Ray Fabrics, said, Lace, shimmer, silky and sexy

fabrics will always be there, but fashion is less important. Performance and comfort are what sells

today.Were looking at new fibers and yarns, Cobb continued. Last year, we came out with our Xen

Collection, which is a blend of Supima/Micromodal. The fabrics are soft, relaxed and comfortable.

They are taking off for yoga wear, a very hot activity.French knitter Billon Frs reports lacy knits

are its biggest seller for lingerie. Very fine Lycra®-content fabrics, tiny floral-patterned

jacquards, diagonal stripes, lightweight fabrics with slick finishes or softly sueded surfaces are

other popular items. Color-reverse double-faced fabrics are also of note. Growth In North

AmericaVirgil Simons, general manager, United States, Dogi International Fabrics, said that value,

product innovation, quality and service are contributors to Dogis success. He added that with the

North American Free Trade Agreement (NAFTA) and the Caribbean Basin Initiative (CBI), there will be

major growth in North America. Dogi is headquartered in Spain, with marketing offices around the

world. You need to be there with your customer, Simons said.Dogi produces a variety of knitted and

woven apparel fabrics, including circular, single and warp knits; and electronic jacquards.

Eighty-four percent of its fabrics are sold for intimate apparel. Last April, the company acquired

four Penn Elastic factories from the Sara Lee Corp., giving them manufacturing capacity in Europe,

the Asia/Pacific region and the Americas.Simons sees growth in activewear, with areas like

cheerleading and classical dance being exceptional. Danskin and Capezio are some of the companies

Dogi sells to in this area. The activewear line takes its direction from fashion and adds

performance. A sanded microdenier fabric for warm-ups is knitted using Meryl®/ Lycra.

Supplex®/Lycra in solid rib coordinates is going into juniors.A recent innovation for intimate

apparel and dancewear is stretch fabrics with engineered zones, providing more stretch in certain

portions of the fabric. Extra muscle support in key areas relieves fatigue; softer stretch in other

areas gives extra comfort.Narrow-width fabrics with selvages that provide clean, finished edges;

moldable fabrics for the bra market; and moisture-transport mesh are other recent Dogi

developments.For mens underwear, Dogi is selling a heather-shaded cotton/nylon/ Lycra opaque/sheer

stripe. A lot of the same fabrics are selling for underfashions for men and women. Victorias

Secret, Vanity Fair and Triumph are among the companys customers. New TechnologiesNew fabrics

introduced at Interfili by the British company Berne-Welbeck focus on new technology to provide

both fashion and performance. Airpak® two-sided fabrics with cushioned centers were shown at

Premiere Vision in October 2001. This range is now available embossed with a broad design

selection. Airpak fabrics are breathable, moldable and easy-care.A group of lux surface effects

includes transparent polyester meshes with embossed designs, wet-look sheers, moirffects and cir

There are iridescent fabrics that have a fluid appearance, and jacquards and coordinates with a

shimmering luster.Other Berne-Welbeck fabrics for intimate apparel are knitted with DuPonts Tactel®

Strata. These include monofilament stripes, metallics and two-colored jacquards. A range described

as Second Skin fabrics has a paper touch or silky hand. The Natural Collection incorporates viscose

with elastane and ProModal to impart a natural touch.There are moisture-management fabrics

containing Supplex and Coolmax® in a Berne-Welbeck collection called Sporty. These include ribs and

tubular jacquards for swimwear and activewear.X-Static®, the silver-coated textile fiber from Noble

Fiber Technologies is going into a broad range of new fabrics in both filament and spun varieties.

At Premiere Vision, Berne-Welbeck featured X-Static in a fabric collection for bras and sportswear.

Fabrics have thermodynamic properties, and are anti-static and anti-odor.The Star Groups Lance T.

Whitaker, vice president, sales and marketing, said that in narrow fabrics, as a secondary

supplier, we have less control. With full-package manufacturing now coming out of the CBI, sources

can become hidden. Because were not the main part of the garment, it is difficult to mandate that

they use our product.The Star Groups answer is to become more innovative. Some of its recent

developments are microdenier channeling for glue bras; sonic seaming for nylon taffeta; and

micro-brushed products providing added comfort for bras. Our narrow fabrics and trimmings give

intimate apparel both visual and tactile appeal, said Whitaker. FashionThe number-one selling

bra in America today is Vanity Fairs (VF) Illumination, a lightly lined seamless bra knitted with

Tactel Strata. In panties, the best-sellers are low-rise seamless styles knitted in

microfibers.Vanity Fairs Ellen Rohde, president, VF Intimates, reports there will be a return to

shine and femininity for Spring/Summer 03. Lace is cyclical and on the upswing. Underwire bras are

also in an up-cycle. Seamless, molded and racer-back bras are other popular items, she said. There

is a resurgence of cotton and cotton-touch fabrics. Cotton connotes comfort, she added. Alice

Papazian, who handles color development and print design for VF Intimates, said colors of inner

fashion closely follow outerwear. Bras and camis have been designed to show.For Spring, Papazian

shows three color ranges: washed-out and whitened pales; vintage shades; and fun, young brights.

And there will be a lot of white. She sees a continuation of sheers, embroidery and lace.By the end

of the year, all VF apparel production in the United States will cease. Garments will come from

Mexico, the Caribbean Basin and the Far East.

At Jockey International, Anne Ewing, senior designer, Intimates, Jockey Brand, said, Intimate

apparel is a comfort-driven product and not a high-ticket item. Our business is healthy.A year ago,

Jockey introduced a line called No Panty Line Promise. It was an instant success. This year, it has

added a mesh collection knitted in a blend of 80-percent Tactel and 20-percent Lycra. There are

thong, brief and bikini styles with coordinating bras.

The Jockey Spring 03 collection is all about comfort. There are cotton/Lycra fabrics knitted

using Santoni seamless machines, as well as nylon/Lycra- and microdenier-content fabrics. Ewing

shows a lot of lace. Some is cross-dyed in fashion colors. Most is shown in coordinating sets. New

prints are floral and leaf designs and all-over metallic to give a shimmer to garments. Bra styles

are underwires, padded with seamless cups, and softer, under-constructed styles. Many use bonded

fabrics and are almost stitch-free, made with ultrasonic and seamless equipment. Seam-free

underwire bras using a flat wire are new.Colors are more sophisticated with outerwear influences. A

small, outlined floral is shown in a combination of black on gray. For Spring 03, Ewing said colors

will be soft and feminine. Along with bras and panties, there are coordinating camis. Some are

ruffled and lace-trimmed, others are padded. Plus sizes are available in a lot of styles. At

Liz Claiborne Intimates, a full-fit collection was recently introduced that is fashionable,

lightweight and sexy. One popular bra is the seamless minimizer, available in soft, stretch lace

with mesh details that reduce the cup by one entire size.

Editor’s Note: In March, Textile World published the first of a two-part feature about the

hottest trends in the intimate apparel industry. In this issue, New York Correspondent Virginia S.

Borland continues her look at the products and processes that are turning heads in this dynamic

market segment.

April 2002

Singapore Trade Agreement May Include Strict Rule Of Origin For Textiles

By James A. Morrissey, Washington CorrespondentU.S. government trade officials are supporting a

“yarn forward” rule of origin in a proposed U.S.-Singapore Free Trade agreement, a move that

pleases U.S. textile manufacturers but gives importers and overseas exporters heartburn. The rule

of origin would be similar to that of the North American Free Trade Agreement (NAFTA), which

requires products benefiting from the free trade pact to be made with yarn and fabric in the

participating nations. It is designed to help the U.S. textile industry and guard against

transshipments of apparel where the yarn or fabric may be made in another country. The U.S.

Association of Importers of Textiles and Apparel has told the U.S. Trade representative that a

NAFTA-like rule of origin for Singapore would be “inappropriate” and said, instead, a “substantial

transformation standard” with a 35-percent value-added requirement would make more sense. The

Singapore Free Trade Agreement is particularly significant, since the U.S. Trade Representative has

announced plans to expand it to include Indonesia.