Companies displayed cutting-edge technologies for 3D garment simulation at ITMA 2023

By Seonyoung Youn

Garment production encompasses three primary manufacturing methods: cut-and-sew, fully-fashioned and whole garment. While cut-and-sew is widely used for its speed, it involves labor-intensive tasks and generates significant waste from leftover fabric pieces during cutting. In contrast, fully-fashioned eliminates cutting by shaping the pieces with finished edges, although it requires assembly. On the other hand, whole garment is an innovative solution that knits the entire garment in one seamless piece, eliminating the need for cutting and sewing while reducing waste yarns. However, it is slower and more suitable for sampling, making it the most expensive option.1

The advent of 3D digital technology has revolutionized garment manufacturing processes. Virtual samples have remarkably reduced material waste and labor-intensive tasks throughout the supply chain, specifically during the preproduction stages, such as 2D pattern design, fabric arrangement, fabric cutting, garment sewing, and fitting.2 Traditionally, these tasks consumed a substantial lead time in garment manufacturing processes. However, virtual sampling allows easy modification and has significantly reduced the average lead time from 37 days to 27 hours.3 Additionally, the COVID-19 pandemic underlined the challenges of in-person communication between buyers, manufacturers, and outsourcing contractors during lockdowns. Consequently, digitalization has transitioned from optional to necessity, accelerating the demand for effective communication. This shift is particularly prominent among global brands, outsourcing agents, vendors and contractors.3

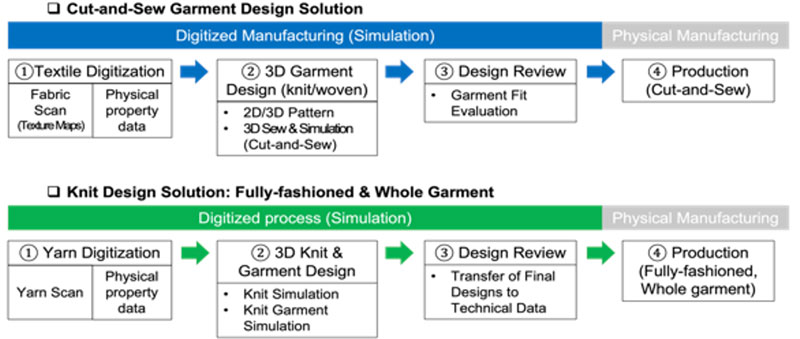

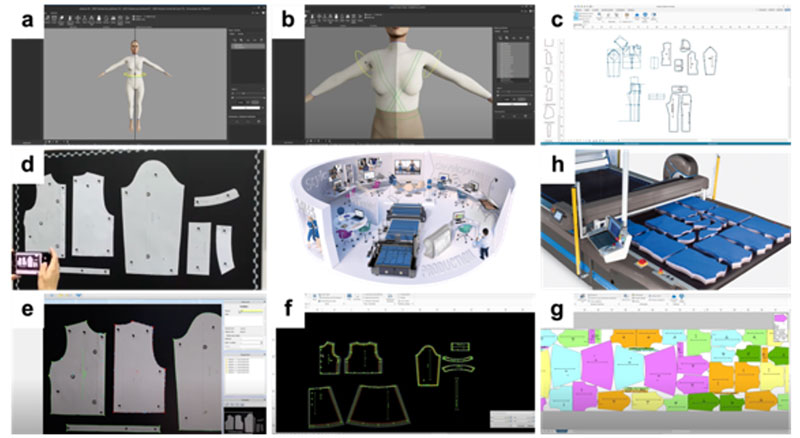

This paper investigates the revolutionization of textile and apparel manufacturing through digitization and advanced garment design solutions. Drawing on observations from ITMA 2023, the focus is on digital technology advancements within the cut-and-sew and knit designs including whole garment production. By examining these advancements, the paper provides valuable insights into the impact of digitization on the textile and apparel industry. Figure 1 illustrates an overview of manufacturing types and their phases using digital simulation technology.

Cut-and-Sew 3D Garment Design Solutions

Global providers of 3D garment design software catering to both woven and knit garment production include CLO3D from South Korea-based CLO Virtual Fashion Inc.; VStitcher from Singapore-based Browzwear; France-based Lectra’s Modaris and Gerber’s AccuMark; Optitex from the FOG Software Group, Rosemont, Ill.; Japan-based Shima Seiki Mfg. Ltd.’s APEXFiz; Style 3D from China-based Linctex; Audaces360 from Brazil-based Audaces; and Adobe Substance from Adobe Inc., San Jose, Calif.

This paper focuses explicitly on advancements showcased at ITMA 2023 for each manufacturing process facilitated by 3D garment software. The cut-and-sew garment design process using digital simulation can be subdivided into four detailed phases — textile digitization, 2D/3D pattern design, 3D sewing and simulation and design review, or fit evaluation, before physical manufacturing.

Advancements In Textile Digitization

Textile digitization plays a crucial role in the initial stage of 3D garment simulation by providing precise physical property data for virtual fabric representation. This process involves capturing the materials’ visual and mechanical properties for realistic simulation. Typically, textile digitization involves manual measurements of physical properties using standard testing equipment or fabric kits provided by the software. These measurements, such as weight, thickness, stretch, and bending properties, are input data for simulating textiles in a virtual environment. However, this manual process takes approximately 20 minutes to measure each data set for a single fabric sample. For example, software like CLO 3D requires 23 input parameters of physical properties for simulating virtual fabrics. In addition to weight and thickness, users are required to measure stretch properties by testing tensile strength at five constant extensions in different directions — warp/wale, weft/course and bias. Bending properties necessitates measuring the fabric’s contact and bending distances in each direction. Although investing in an accurate representation of virtual material ensures precision, the manual process may not be efficient enough to meet the demands of fast fashion.

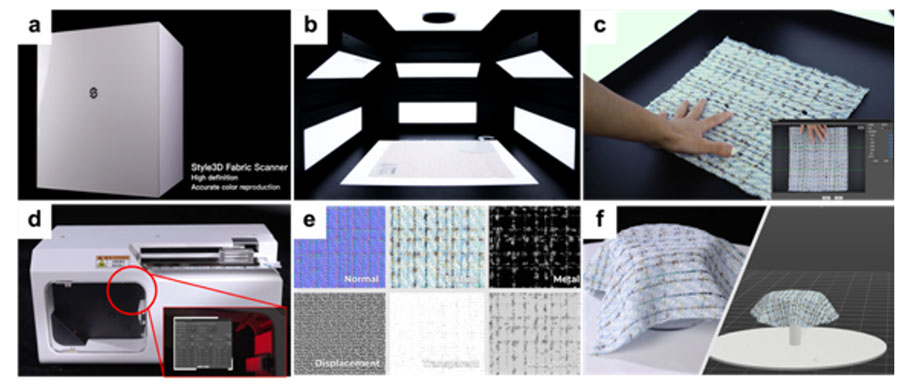

Automated textile digitization tools have emerged to address this challenge, focusing on ease of use, speed, reliability, and simplicity through computerized techniques. At ITMA 2023, Linctex, provider of Style 3D software, showcased three automated devices for textile digitization — the Style 3D fabric scanner, Style 3D bending tester and Style 3D tensile tester. These devices are fully integrated with the Style 3D software, enabling them to measure the required physical properties, as depicted in Figure 2.

First, users scan the fabric’s texture using the computerized fabric scanner. The fabric scanner incorporates a high-quality Nikon SLR camera equipped with 10 LEDs to digitally capture the fabric’s surface properties. The scanner has a lens that maintains a consistent-controlled light source to ensure accurate results and high-accuracy brightness balance. The fabric scanner eliminates manual data entry and ensures efficiency (See Figures 2a-c).

Additionally, the showcase includes a Style 3D bending and tensile tester that automates the evaluation of fabric’s physical properties, eliminating the need for manual measurement. The tensile tester accurately measures stretch strength up to 0.01 Newton with a precision of ± 0.5%. Meanwhile, the bending tester utilizes laser sensors to detect the fabric’s bending length in the weft, warp, and bias directions (See Figure 2d). The obtained physical properties and AI-generated fabric texture maps can be seamlessly uploaded into Style 3D’s design software (See Figure 2e). These 3D digital files incorporate texture maps and digitized physical properties, enabling comprehensive data for realistic fabric simulation (See Figure 2f). Furthermore, the finalized digital file format, .u3ma, is compatible with other 3D simulation software.

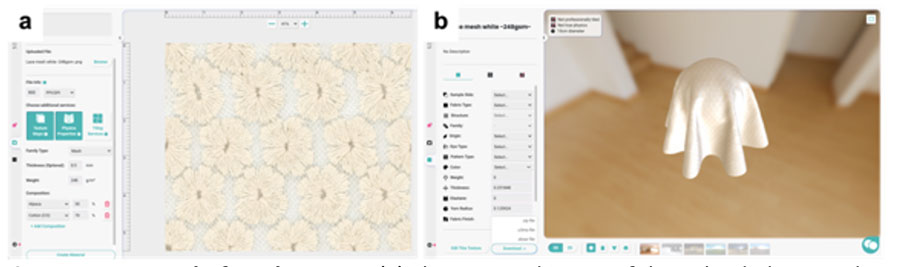

Another innovative solution showcased at the ITMA 2023 is SEDDI’s Textura™ platform. The platform employs artificial intelligence (AI) technology to revolutionize the process of textile digitization. In contrast to conventional approaches that necessitate expensive equipment, SEDDI’s Textura offers a streamlined solution. By simply scanning a fabric surface with any scanner and entering four essential fabric details — weight, thickness, fabric types, and fiber compositions — Textura automatically generates digitized physical properties resulting in a 3D digital file available for download in various formats such as .zip, .u3ma, and .sbsar files (See Figure 3). The entire process can be completed within approximately five minutes, from scanning an image to downloading the digitalized files.

The AI-powered platform incorporates cutting-edge technologies, including Artificial Neural Network (ANN) and Digital Image Analysis (DIA) algorithms commonly employed in image analysis and computer vision. These algorithms can estimate yarn and fabric properties parameters.4 SEDDI’s Textura is a cloud-based operation, eliminating users’ need to invest in expensive hardware for installation or regularly purchase updates. Instead, they can benefit from automatic updates, ensuring they stay updated with the latest improvements.

Advancements In 2D/3D Pattern Design

Traditionally, the 2D/3D pattern design process involved starting with 2D paper patterns or draping on a 3D mannequin and then transferring the markings from 3D to 2D patterns. However, with advanced 3D design software, designers can now seamlessly and simultaneously explore 2D to 3D and 3D to 2D design approaches using digital technologies.

One notable solution in this field showcased at ITMA 2023 is AUDACES 360® by Audaces. AUDACES 360 presents an all-in-one solution that integrates multiple productive phases of the design process. This comprehensive package includes various platforms designed to streamline different aspects of the workflow. Among the innovative approaches demonstrated by AUDACES 360, two stand out in the context of the 2D/3D pattern design process. The first approach utilizes the Fashion Studio® platform, which enables designers to flatten 2D patterns from a 3D mannequin by dissecting fitted garments (See Figures 4a-b). This 3D-to-2D flatten technology allows for adjustments in length, volume, color/pattern placements and materials (See Figure 4c). This technique is particularly beneficial for users without a background in pattern design, as it facilitates the creation of complicated garments like dresses by allowing them to experiment with individual panel pieces on the 3D mannequin.

The second approach involves the Digiflash® platform, which efficiently and precisely digitizes pattern paper. By capturing a photo of pattern templates stored by the company, the Digiflash effortlessly captures the 2D pattern details and transfers them into a digital format. Once digitized, the Pattern® platform enables precise modifications and automated size grading (See Figures 4d-f). The Marker® and Supera® platforms also optimize efficiency by automatically generating fabric markers and managing marking queues (See Figures 4g-h). With the comprehensive platform provided by AUDACES 360, designers can seamlessly transition between 2D and 3D design approaches, resulting in a streamlined pattern design process.

Advancements In 3D Sewing And Simulation

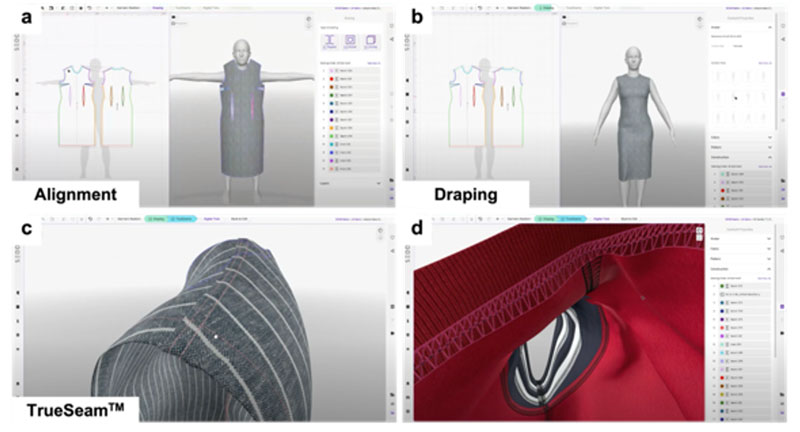

At ITMA 2023, SEDDI unveiled Author™, a cutting-edge innovation that introduced several vital advancements including its cloud-native capability. The cloud-native feature enables seamless collaboration among stakeholders such as designers, pattern makers, and buyers, facilitating real-time communication and streamlined workflows. SEDDI Author introduces two game-changing functions: True Seam™ and Digital Twin™. True Seam revolutionizes 3D garment prototyping by accurately simulating the impact of physical properties of seam construction on the garment, such as stitch types, seam types, and the number of folds. Unlike modern 3D design software that overlooks these crucial details, True Seam empowers designers to make informed decisions in real time, enhancing the reliability of 3D simulations for production. The overview of 3D prototyping using True Seam is depicted in Figure 5.

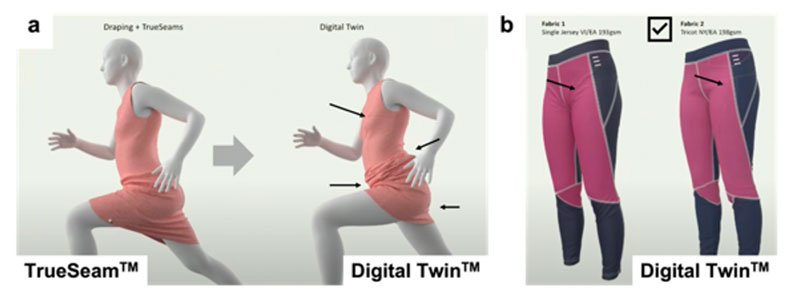

Following True Seam’s feature, the next level is Digital Twin, bringing the virtual garment even closer to realism. By simulating the dynamic postures of the avatar, Digital Twin represents the physical behavior of the garment construction and how the seams interact when the avatar moves. For example, Figure 6 highlights the difference between True Seam and Digital Twin modes in the real-time Author™ platform.

The Digital Twin technology accurately captures the realistic behavior of fabric, including its stretching over the avatar’s legs and natural bunching, resulting in an authentic representation. In Figure 6a, the technology accounts for intricate details, such as lifting bust darts due to the avatar’s motion, attributed to surface friction and mechanical interaction between the fabric and the skin. This simulation reproduces real-life body movements, enhancing the high-fidelity of the virtual representation. Moreover, as shown in Figure 6b, the Digital Twin enables designers to make subtle adjustments, such as optimizing creases in the crotch area, without modifying the entire 2D pattern, thereby reducing fabric waste. Designers can decide to choose the proper material from the previous single jersey fabric, composed of viscose and elastane at 193 grams per square meter (gsm), to Tricot fabric, composed of nylon and elastane at 198 gsm, based on the virtual simulation prior to physical production. This informed decision-making process is facilitated by the Digital Twin features, which assist designers in selecting the most suitable material throughout garment manufacturing.

Advancements In Garment Fitting Evaluation

Fitting evaluation is the final phase before creating physical samples. Virtual fitting involves objective measurements to assess the garment fit and the wearer’s pressure comfort.5 In this context, simulated stress and strain are essential mechanical properties to evaluate garment fit. Garment stress refers to the internal forces and pressure exerted on the fabric and seams when worn or subjected to movement, measured in kilopascals (kPa). Garment strain, on the other hand, refers to the fabric’s deformation or elongation in response to applied stress, measured as a percentage.6

During ITMA 2023, Style3D design software showcased an advanced feature that introduces further enhancements to fitting evaluation. The new feature lets designers modify the avatar’s body proportions while evaluating the fit through stress and strain. Unlike the traditional approach, where designers work with a fixed avatar shape, cutting-edge technology allows for changes in body sizes — leg, shoulder, neck, height, bust, thigh and arm length — and facial expressions, poses, and animations. By incorporating dynamic body modifications, designers can better understand how garments will fit various body types and sizes, ultimately enhancing the accuracy and effectiveness of fitting evaluations. Figure 7 illustrates how the software can simulate the wearer’s fit with the garment by changing the circumference of her belly to simulate pregnancy.

Knit Design Solutions: Whole Garment; Advancement In 3D Knit Garment Design

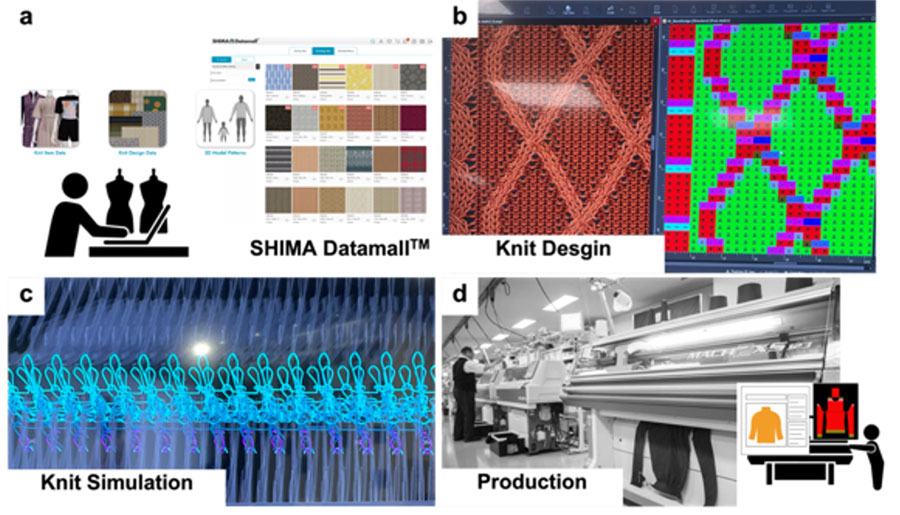

Digital technology has transformed garment production, surpassing traditional cut-and-sew methods. An innovative approach is fully-fashioned or whole garment production, pioneered by Shima Seiki. Using advanced computerized knitting machines, Shima Seiki enables seamless construction of complete garments, including sleeves, body and neckline. This eliminates the need for separate fabric panels, reducing materials consumption and manual labor. At ITMA 2023, Shima Seiki unveiled APEXFiz™, its updated software featuring a comprehensive suite of design tools. Tailored to meet diverse user needs, the software includes Design-Knit for flat and circular knit designers, and Design-Weave for weave and towel designers. A centralized data bank called Shima Datamall™ provides efficient storage and search functionality for yarn, knit, design, and 3D pattern data. This integrated approach streamlines knit garment production planning, allowing designers to efficiently locate and utilize necessary resources (See Figure 8a).

Designers can seamlessly incorporate the downloaded yarn, knit design, or pattern data into their chosen design program. The APEXFiz software empowers designers to create technical lines that accurately represent their desired knit structure. By designing these lines alongside the knit structures, users can assign specific stitch types and patterns to each line, thus determining the construction of the knit product (See Figure 8b). Once the knit sample is completed, they can simulate the knitting process in the virtual V-bed flat machine. This step allows them to assess their design’s feasibility and visualize their knit product’s outcome (See Figure 8c). Upon finalizing the design of the knit structure, the software generates output files that contain essential information, including stitch data, technical specifications, and color details. These files are crucial for the technical production process. A notable advantage is a seamless integration between Shima Seiki’s design software and their physical V-bed knitting machines, enabling a straightforward transfer of the knit data files. This streamlined process greatly facilitates physical production (See Figure 8d).

Breaking Barriers: Advancements In Seamless Communication Between Yarn And 3D Garment Simulation

There are distinctions between yarn-level simulation software, such as Shima Seiki’s knitting software, and cut-and-sew 3D garment simulation software, like Style 3D, CLO 3D, for example. Yarn simulation takes a bottom-up approach, simulating yarn properties, including yarn types, denier, density, thickness, weight, stitch density, and knit structures.7 In contrast, cut-and-sew 3D garment simulation software employs a top-down approach, relying on fabric-level physical properties representation, employing techniques like discretization and a mass-spring model.8 When it comes to visual representation of knit construction in 3D garment simulation, scanned fabric images are utilized to generate texture maps, distinguishing it from yarn-level simulation. Because of these fundamental modeling differences, seamless compatibility between yarn and 3D garment simulation software is not attainable. Figure 9 visually illustrates typical issues that arise when knitting files are transferred to external 3D software, resulting in unrealistic stitch transitions, misalignment between rib and body structure stitches, and the absence of stitch decreases and fully fashioned marks.

The lack of integration between virtual sampling and technical production can lead to impractical outcomes that are difficult to knit. To bridge the gap between yarn and 3D garment simulation, Karl Mayer Group has introduced k.innovation CREATE DESIGN and k.innovation CREATE PLUS (KM.ON). This comprehensive digital solution, showcased at ITMA 2023, revolutionizes the textile industry workflow by digitizing every step and addressing the challenges of accurately representing visual knit construction with any 3D external garment design software, as illustrated in Figure 10.

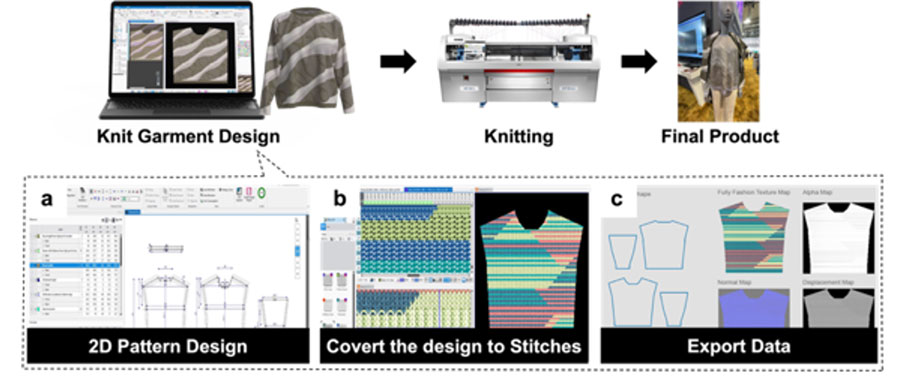

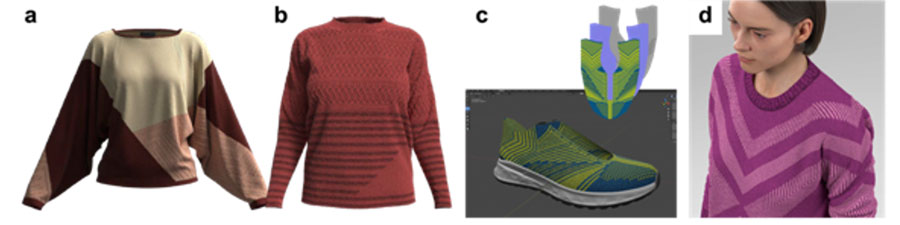

The workflow with KM.ON consists of three main steps. To proceed with knit design, designers can construct a 3D shape based on the 2D pattern design. They can utilize pre-set templates or import a DXF file for added flexibility (See Figure 10a). Then, the 3D shape is converted into knit stitches using features such as stitch libraries, jacquard/intarsia patterns, color reduction, and technical checks. This seamless transition from 3D design to technical data ensures a smooth integration (See Figure 10b). The finalized design can be exported as knit texture maps for external 3D garment design software utilization. The knit data includes a DXF file, Fully Fashioned Texture Map, Alpha Map, Normal Map, and Displacement Map (See Figure 10c). These data elements are crucial for achieving a highly realistic representation of fabric texture in the 3D garment design program. Finally, Figure 11 displays successful examples of knit apparel prototypes, demonstrating their compatibility with various external 3D software tools.

Conclusion

ITMA 2023 served as a platform to showcase remarkable technological innovations in digitized garment manufacturing. Companies presented advancements in software, highlighting the importance of digitalization, automation, reliability, versatility, and sustainability on all-in-one platforms. While the industry embraces digital solutions, ensuring reliability and accuracy in virtualized textiles remains a significant challenge due to the absence of standardized testing methods. Thoroughly examining the mechanical and visual representations is essential to instill confidence in the virtualized textile and ensure seamless physical production. The user’s perception of virtual fabric and garments also plays a vital role. Establishing practical correlations between numerical evaluations of garment fit and the wearer’s comfort or perception is imperative. By addressing these challenges, the full potential of digitization and advanced garment design can be realized, enhancing reliability and acceptance within the textile and apparel industry.

References

- Larsson, J., Mouwitz, P., & Peterson, J. (2013). Knit on Demand—Mass customisation of knitted fashion products. Textile Journal.

- Weinswig, D. (2017). Deep Dive: An Overview of the Digitalization of the Apparel Supply Chain.

- Hwang Shin, S.-J., & Lee, H. (2020). The use of 3D virtual fitting technology: Comparison between sourcing agents contractors and domestic suppliers in the apparel industry. International Journal of Fashion Design, Technology and Education, 13(3), 300–307.

- Carvalho, V., Cardoso, P., Belsley, M., Vasconcelos, R. M., & Soares, F. O. (2006). Development of a Yarn Evenness Measurement and Hairiness Analysis System. IECON 2006 – 32nd Annual Conference on IEEE Industrial Electronics, 3621–3626.

- Youn, S., Mathur, K., Knowles, C., Ju, B., Sennik, B., & Jur, J. (2023). Simulation-based Prediction Model to Optimize Contact Pressure of Knitted Fabrics for Wearable Garments. 9th International Conference on Human Interaction and Emerging Technologies – Artificial Intelligence and Future Applications.

- Fabric Kit Manual. (2020, July 17). How Can We Help You? https://support.clo3d.com/hc/en-us/articles/360041074334-Fabric-Kit-Manual

- Sperl, G., Sánchez-Banderas, R. M., Li, M., Wojtan, C., & Otaduy, M. A. (2022). Estimation of yarn-level simulation models for production fabrics. ACM Transactions on Graphics, 41(4), 1–15.

- Baraff, D., & Witkin, A. (1998). Large steps in cloth simulation. Proceedings of the 25th Annual Conference on Computer Graphics and Interactive Techniques – SIGGRAPH ’98, 43–54.

Editor’s Note: Seonyoung Youn is a Ph.D. student at NC State’s Wilson College of Textiles. Her major is Fiber and Polymer Science and her area of study is e-textile and wearable garment design using digital technology. She expects to graduate this July.

April 21, 2024