CHICAGO — June 7, 2024 — drupa 2024 exceeded all expectations. It received top marks from visitors from all over the world, who left the trade fair with new ideas and clear prospects for the future. Numerous contracts signed and technological innovations inspired the printing and packaging industry.

CHICAGO — June 7, 2024 — drupa 2024 exceeded all expectations. It received top marks from visitors from all over the world, who left the trade fair with new ideas and clear prospects for the future. Numerous contracts signed and technological innovations inspired the printing and packaging industry.

drupa 2024, the world’s trade fair for printing technologies, came to a successful close on June 7 after 11 days in Düsseldorf, Germany. It impressively demonstrated the progress of an entire sector and demonstrated the operational excellence of the industry. A total of 1,643 exhibitors from 52 nations presented an outstanding showcase of innovations in the Düsseldorf exhibition halls and inspired the trade visitors with unforgettable performances. The international share of the visitors was 80 percent, with attendees coming from 174 countries — a record figure. After Europe, Asia was the most strongly represented region with 22 percent, followed by America with 12 percent.

Asia as well as Latin America and the MENA region are markets with great growth potential, which was reflected in the significant increase in exhibitor participation and order books. Many key players, such as Bobst, Canon, Fujifilm, Heidelberger Druckmaschinen, HP, Horizon, Koenig & Bauer, Komori Konica Minolta, Kurz and Landa, reported having signed contracts that significantly exceeded expectations. In some cases, the sales targets set were already achieved in the first few days of the trade fair.

Erhard Wienkamp, Managing Director at Messe Düsseldorf, is highly satisfied with the course of the trade fair: “drupa has underpinned its position as the industry’s leading trade fair and its unique appeal in a remarkable way. The impressive international flair and, above all, the high decision-making competence of the visitors ensured in-depth and well-founded technical discussions at the trade fair stands on the one hand and many direct investment decisions on the other. Our exhibitors told us about large-volume purchase agreements.”

Dr. Andreas Pleßke, Chairman of the drupa Committee, emphasized the exceptional position and relevance of drupa: “drupa stands for new approaches and new technologies like no other trade fair. It is not only the largest, but also the most important global platform for our industry, because the entire printing and post-press industry meets at this the world-leading trade fair. It has been invaluable for generating leads. Nowhere else offers the opportunity to make so many new international contacts from all over the world in such a short space of time in one place.”

Industry decision-makers highly satisfied

Exhibitors praised the high level of decision-making authority of the visitors. They, in turn, gave top marks to the range of products and services on offer in the 18 exhibition halls. Around 96 percent of all visitors confirmed that they had fully achieved the objectives associated with their visit. More than 50 percent came from the printing industry, followed by the packaging industry, whose share has increased significantly and which was the focus of many exhibitors as a growth driver. Many well-known brand owners were welcomed at the trade fair stands. Overall, 170,000 trade visitors attended drupa 2024.

Digitalization as a determining factor

Automation took center stage at this year’s drupa, with a strong focus on AI and smart workflows, including software solutions. It became evident that digital and analogue technologies ideally complement and benefit from each other. Traditional industry leaders presented a wide range of digital solutions, while digital pioneers integrated conventional components into their offerings. Robotics played an important role in the exhibition halls and illustrated the path towards the smart factory.

Transformation and growth

drupa made it very clear that the industry has great potential for the future, even against the backdrop of many challenges and that the prospects are promising. In the last financial year, the global printing industry achieved a turnover of around 840 billion euros (source: Smithers) and continues to develop at varying pace worldwide.

“At drupa 2024, we experienced firsthand just how relevant and resilient this industry is,” summarizes Sabine Geldermann, director drupa, Portfolio Print Technologies. “The community is determined to set the course for the future together. Exchanging ideas with people from all continents and from all areas of the industry was extremely enriching and inspiring. We were able to welcome around 50 large delegations from various nations, and numerous globally active associations and organizations chose drupa as the ideal setting for their conferences and board meetings.”

Together we are stronger. Many new strategic alliances concluded at the trade fair reflected the opportunities that are only possible in such a concentrated form at drupa: meeting market players from other countries around the world in person, using core competences as synergy effects, forming networks and driving the market forward together

Sustainable technologies in focus

Technology is the key to achieving sustainability goals — exhibitors at drupa illustrated this with numerous practice-orientated developments and concrete solutions. Top priority is given to resource efficiency and the path to a functioning circular economy. In addition, Touchpoint Sustainability from the German Machinery and Equipment Manufacturers’ Association (VDMA) showcased current state of the art innovations, presented best-practice use cases and gave a far-reaching outlook into the future of a sustainable printing industry.

Valuable knowledge transfer

The extensive supporting program with its five high-caliber special forums drupa cube, drupa next age (dna) and the Touchpoints Packaging, Textile and Sustainability was very well received. In times of constant change and the resulting new business models, they ensured an intensive transfer of knowledge and provided important guidance. Together with its partners, drupa focused on impressive industry expertise and the future topics of its target groups. Guided tours on various key topics rounded off the trade fair experience.

The next staging of drupa will be in 2028 in Düsseldorf, Germany. For further information on visiting or exhibiting at drupa 2028, contact Messe Düsseldorf North America; E-mail: info@mdna.com; Visit www.drupa.com and www.mdna.com.

Posted: June 7, 2024

Source: Messe Düsseldorf North America

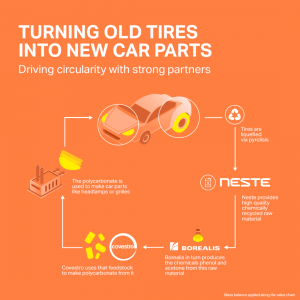

VIENNA, Austria — June 11, 2024 — Neste, Borealis and Covestro have signed a project agreement to enable the recycling of discarded tires into high-quality plastics for automotive applications. The collaboration aims at driving circularity in plastics value chains and the automotive industry. When no longer fit for use, tires are liquefied by means of chemical recycling and then processed into base chemicals and further into polycarbonates of high purity. These can then be used in various automotive applications, from parts of headlamps to radiator grills.

VIENNA, Austria — June 11, 2024 — Neste, Borealis and Covestro have signed a project agreement to enable the recycling of discarded tires into high-quality plastics for automotive applications. The collaboration aims at driving circularity in plastics value chains and the automotive industry. When no longer fit for use, tires are liquefied by means of chemical recycling and then processed into base chemicals and further into polycarbonates of high purity. These can then be used in various automotive applications, from parts of headlamps to radiator grills.