TEMPE, Ariz. — July 1, 2024 — Economic activity in the manufacturing sector contracted in June for the third consecutive month and the 19th time in the last 20 months, say the nation’s supply executives in the latest Manufacturing ISM® Report On Business®.

TEMPE, Ariz. — July 1, 2024 — Economic activity in the manufacturing sector contracted in June for the third consecutive month and the 19th time in the last 20 months, say the nation’s supply executives in the latest Manufacturing ISM® Report On Business®.

The report was issued today by Timothy R. Fiore, CPSM, C.P.M., Chair of the Institute for Supply Management® (ISM®) Manufacturing Business Survey Committee:

“The Manufacturing PMI® registered 48.5 percent in June, down 0.2 percentage point from the 48.7 percent recorded in May. The overall economy continued in expansion for the 50th month after one month of contraction in April 2020. (A Manufacturing PMI® above 42.5 percent, over a period of time, generally indicates an expansion of the overall economy.) The New Orders Index remained in contraction territory, registering 49.3 percent, 3.9 percentage points higher than the 45.4 percent recorded in May. The June reading of the Production Index (48.5 percent) is 1.7 percentage points lower than May’s figure of 50.2 percent. The Prices Index registered 52.1 percent, down 4.9 percentage points compared to the reading of 57 percent in May. The Backlog of Orders Index registered 41.7 percent, down 0.7 percentage point compared to the 42.4 percent recorded in May. The Employment Index registered 49.3 percent, down 1.8 percentage points from May’s figure of 51.1 percent.

“The Supplier Deliveries Index remained in ‘faster’ territory, registering 49.8 percent, 0.9 percentage point higher than the 48.9 percent recorded in May. (Supplier Deliveries is the only ISM® Report On Business® index that is inversed; a reading of above 50 percent indicates slower deliveries, which is typical as the economy improves and customer demand increases.) The Inventories Index registered 45.4 percent, down 2.5 percentage points compared to May’s reading of 47.9 percent.

“The New Export Orders Index reading of 48.8 percent is 1.8 percentage points lower than the 50.6 percent registered in May. The Imports Index dropped into contraction territory, registering 48.5 percent, 2.6 percentage point lower than the 51.1 percent reported in May.”

Fiore continues, “U.S. manufacturing activity continued in contraction at the close of the second quarter. Demand was weak again, output declined, and inputs stayed accommodative. Demand slowing was reflected by the (1) New Orders Index improving to marginal contraction, (2) New Export Orders Index returning to contraction, (3) Backlog of Orders Index dropping into stronger contraction territory, and (4) Customers’ Inventories Index moving into the low side of the ‘just right’ range, neutral for future production. Output(measured by the Production and Employment indexes) declined compared to May, with a combined 3.5-percentage point downward impact on the Manufacturing PMI® calculation. Panelists’ companies reduced production levels month over month as head count reductions continued in June. Inputs — defined as supplier deliveries, inventories, prices and imports — continued to accommodate future demand growth. The Prices Index eased but remained in expansion (or ‘increasing’) territory; the index registered its second month of cooling increases.

“Demand remains subdued, as companies demonstrate an unwillingness to invest in capital and inventory due to current monetary policy and other conditions. Production execution was down compared to the previous month, likely causing revenue declines, putting pressure on profitability. Suppliers continue to have capacity, with lead times improving and shortages not as severe. Sixty-two percent of manufacturing gross domestic product (GDP) contracted in June, up from 55 percent in May. More concerning is the share of sector GDP registering a composite PMI® calculation at or below 45 percent — a good barometer of overall manufacturing weakness — was 14 percent in June, 10 percentage points higher than the 4 percent reported in May,” says Fiore.

The eight manufacturing industries reporting growth in June — in order — are: Printing & Related Support Activities; Petroleum & Coal Products; Primary Metals; Furniture & Related Products; Paper Products; Chemical Products; Miscellaneous Manufacturing; and Nonmetallic Mineral Products. The nine industries reporting contraction in June — in the following order — are: Textile Mills; Machinery; Fabricated Metal Products; Wood Products; Transportation Equipment; Plastics & Rubber Products; Food, Beverage & Tobacco Products; Electrical Equipment, Appliances & Components; and Computer & Electronic Products.

WHAT RESPONDENTS ARE SAYING

“High volume of customer orders.” [Chemical Products]

“Customers continue to cut orders with short notice, causing a ripple effect throughout lower-tier suppliers.” [Transportation Equipment]

“Consumer demand and inventories are no longer stable at retail and food service establishments.” [Food, Beverage & Tobacco Products]

“While orders are still steady, inventory from the previous month is enough to satisfy current- and near-term commitments.” [Computer & Electronic Products]

“Customers ordering more to create buffer stocks (in case of) future shortages.” [Electrical Equipment, Appliances & Components]

“Order levels in two of our main divisions are indicating weak demand, and now we must work to reduce inventory levels.” [Fabricated Metal Products]

“Sales backlog is decreasing. We have furloughed a portion of our workforce as a result.” [Machinery]

“The level of production is lower due to decreased demand for products.” [Miscellaneous Manufacturing]

“Elevated financing costs have dampened demand for residential investment. We have reduced inventories of production components.” [Wood Products]

“Orders have increased slightly due to seasonal restocking.” [Plastics & Rubber Products]

MANUFACTURING AT A GLANCE

June 2024 |

| Index |

Series

Index

Jun |

Series

Index

May |

Percentage

Point

Change |

Direction |

Rate of

Change |

Trend*

(Months) |

| Manufacturing PMI® |

48.5 |

48.7 |

-0.2 |

Contracting |

Faster |

3 |

| New Orders |

49.3 |

45.4 |

+3.9 |

Contracting |

Slower |

3 |

| Production |

48.5 |

50.2 |

-1.7 |

Contracting |

From Growing |

1 |

| Employment |

49.3 |

51.1 |

-1.8 |

Contracting |

From Growing |

1 |

| Supplier Deliveries |

49.8 |

48.9 |

+0.9 |

Faster |

Slower |

4 |

| Inventories |

45.4 |

47.9 |

-2.5 |

Contracting |

Faster |

17 |

| Customers’ Inventories |

47.4 |

48.3 |

-0.9 |

Too Low |

Faster |

7 |

| Prices |

52.1 |

57.0 |

-4.9 |

Increasing |

Slower |

6 |

| Backlog of Orders |

41.7 |

42.4 |

-0.7 |

Contracting |

Faster |

21 |

| New Export Orders |

48.8 |

50.6 |

-1.8 |

Contracting |

From Growing |

1 |

| Imports |

48.5 |

51.1 |

-2.6 |

Contracting |

From Growing |

1 |

| OVERALL ECONOMY |

Growing |

Slower |

50 |

| Manufacturing Sector |

Contracting |

Faster |

3 |

Manufacturing ISM® Report On Business® data is seasonally adjusted for the New Orders, Production, Employment and Inventories indexes.

*Number of months moving in current direction.

COMMODITIES REPORTED UP/DOWN IN PRICE AND IN SHORT SUPPLY

Commodities Up in Price

Aluminum (7); Aluminum Products; Copper (3); Electrical Components (2); Labor — Temporary (2); Ocean Freight (2); Plastic Resins (6); Rubber Compounds; and Titanium Dioxide.

Commodities Down in Price

Polypropylene; Solvents; Steel (2); Steel — Carbon (3); Steel — Hot Rolled (2); Steel — Scrap (2); and Steel Products.

Commodities in Short Supply

Electrical Components (45); Electronic Components (3); and Steel — Carbon.

Note: The number of consecutive months the commodity is listed is indicated after each item.

JUNE 2024 MANUFACTURING INDEX SUMMARIES

Manufacturing PMI®

The U.S. manufacturing sector contracted for the third consecutive month in June, as the Manufacturing PMI® registered 48.5 percent, down 0.2 percentage point compared to May’s reading of 48.7 percent. “After breaking a 16-month streak of contraction by expanding in March, the manufacturing sector has contracted the last three months, and at a faster rate in June. None of five subindexes that directly factor into the Manufacturing PMI® were in expansion territory, down from two in May. The New Orders Index remained in contraction but moved upward in June. Of the six biggest manufacturing industries, only one (Chemical Products) registered growth in June,” says Fiore. A reading above 50 percent indicates that the manufacturing sector is generally expanding; below 50 percent indicates that it is generally contracting.

A Manufacturing PMI® above 42.5 percent, over a period of time, generally indicates an expansion of the overall economy. Therefore, the June Manufacturing PMI® indicates the overall economy grew for the 50th straight month after one month of contraction (April 2020). “The past relationship between the Manufacturing PMI® and the overall economy indicates that the June reading (48.5 percent) corresponds to a change of plus-1.7 percent in real gross domestic product (GDP) on an annualized basis,” says Fiore.

THE LAST 12 MONTHS

| Month |

Manufacturing

PMI® |

Month |

Manufacturing

PMI® |

| Jun 2024 |

48.5 |

Dec 2023 |

47.1 |

| May 2024 |

48.7 |

Nov 2023 |

46.6 |

| Apr 2024 |

49.2 |

Oct 2023 |

46.9 |

| Mar 2024 |

50.3 |

Sep 2023 |

48.6 |

| Feb 2024 |

47.8 |

Aug 2023 |

47.6 |

| Jan 2024 |

49.1 |

Jul 2023 |

46.5 |

| Average for 12 months – 48.1

High – 50.3

Low – 46.5 |

New Orders

ISM®’s New Orders Index contracted in June for the third month, registering 49.3 percent, an increase of 3.9 percentage points compared to May’s figure of 45.4 percent. The New Orders Index hasn’t indicated consistent growth since a 24-month streak of expansion ended in May 2022. “Of the six largest manufacturing sectors, two (Computer & Electronic Products; and Chemical Products) reported increased new orders. Panelists’ comments noted a continued level of uncertainty and cautiousness as new order levels and customer inventory accounts continue to underperform,” says Fiore. A New Orders Index above 52.3 percent, over time, is generally consistent with an increase in the Census Bureau’s series on manufacturing orders (in constant 2000 dollars).

The six manufacturing industries that reported growth in new orders in June, in order, are: Primary Metals; Petroleum & Coal Products; Furniture & Related Products; Computer & Electronic Products; Chemical Products; and Miscellaneous Manufacturing. The six industries reporting a decline in new orders in June — in the following order — are: Fabricated Metal Products; Textile Mills; Machinery; Transportation Equipment; Electrical Equipment, Appliances & Components; and Food, Beverage & Tobacco Products. Six industries reported no change in new orders in June as compared to May.

| New Orders |

%Higher |

%Same |

%Lower |

Net |

Index |

| Jun 2024 |

20.3 |

59.1 |

20.6 |

-0.3 |

49.3 |

| May 2024 |

19.0 |

57.4 |

23.6 |

-4.6 |

45.4 |

| Apr 2024 |

19.9 |

63.2 |

16.9 |

+3.0 |

49.1 |

| Mar 2024 |

26.1 |

57.7 |

16.2 |

+9.9 |

51.4 |

Production

The Production Index fell into contraction territory in June, registering 48.5 percent, 1.7 percentage points lower than the May reading of 50.2 percent. Of the six largest manufacturing sectors, only one (Chemical Products) reported increased production. “Panelists’ companies marginally reduced output levels compared to May. New order rates remain weak and backlog levels continue to decline, as production output enters contraction territory and companies are hesitant to invest in intermediate goods and finished goods inventory due to economic uncertainty,” says Fiore. An index above 52.2 percent, over time, is generally consistent with an increase in the Federal Reserve Board’s Industrial Production figures.

The eight industries reporting growth in production during the month of June, in order, are: Printing & Related Support Activities; Petroleum & Coal Products; Paper Products; Primary Metals; Furniture & Related Products; Plastics & Rubber Products; Chemical Products; and Miscellaneous Manufacturing. The six industries reporting a decrease in production in June, in order, are: Textile Mills; Fabricated Metal Products; Machinery; Transportation Equipment; Electrical Equipment, Appliances & Components; and Food, Beverage & Tobacco Products.

| Production |

%Higher |

%Same |

%Lower |

Net |

Index |

| Jun 2024 |

22.8 |

56.9 |

20.3 |

+2.5 |

48.5 |

| May 2024 |

19.8 |

62.6 |

17.6 |

+2.2 |

50.2 |

| Apr 2024 |

22.1 |

62.6 |

15.3 |

+6.8 |

51.3 |

| Mar 2024 |

25.3 |

61.7 |

13.0 |

+12.3 |

54.6 |

Employment

ISM®’s Employment Index registered 49.3 percent in June, 1.8 percentage points lower than the May reading of 51.1 percent. “The index indicated employment contracted after an expansion in May which broke a seven-month streak of contraction. Of the six big manufacturing sectors, only one (Fabricated Metal Products) expanded employment in June. Many Business Survey Committee respondents’ companies are continuing to reduce head counts through layoffs, attrition and hiring freezes. Panelists’ comments in June indicated a marginal decline in staff reductions compared to May, supported by the approximately 1.3-to-1 ratio of hiring versus head-count reduction comments,” says Fiore. An Employment Index above 50.3 percent, over time, is generally consistent with an increase in the Bureau of Labor Statistics (BLS) data on manufacturing employment.

Of 18 manufacturing industries, the five industries reporting employment growth in June are: Printing & Related Support Activities; Nonmetallic Mineral Products; Wood Products; Fabricated Metal Products; and Miscellaneous Manufacturing. The six industries reporting a decrease in employment in June, in the following order, are: Textile Mills; Chemical Products; Primary Metals; Plastics & Rubber Products; Electrical Equipment, Appliances & Components; and Machinery. Seven industries reported no change in employment in June as compared to May.

| Employment |

%Higher |

%Same |

%Lower |

Net |

Index |

| Jun 2024 |

16.8 |

66.1 |

17.1 |

-0.3 |

49.3 |

| May 2024 |

17.1 |

69.0 |

13.9 |

+3.2 |

51.1 |

| Apr 2024 |

16.3 |

67.9 |

15.8 |

+0.5 |

48.6 |

| Mar 2024 |

14.1 |

67.8 |

18.1 |

-4.0 |

47.4 |

Supplier Deliveries†

Delivery performance of suppliers to manufacturing organizations was faster in June, with the Supplier Deliveries Index registering 49.8 percent, a 0.9-percentage point gain compared to the reading of 48.9 percent reported in May. This is the fourth consecutive month of faster deliveries after one month of slower performance preceded by 16 straight months in “faster” territory. After a reading of 52.4 percent in September 2022, the index went into contraction territory in October and remained there until February. Of the six big industries, two (Chemical Products; and Machinery) reported slower supplier deliveries in June. “On a consistent basis in 2024, suppliers have supported customers adequately by delivering faster, making more reliable promises and slowly reducing lead times. Panelists continue to predict faster supplier deliveries for the rest of the year,” says Fiore. A reading below 50 percent indicates faster deliveries, while a reading above 50 percent indicates slower deliveries.

The four manufacturing industries reporting slower supplier deliveries in June are: Petroleum & Coal Products; Miscellaneous Manufacturing; Chemical Products; and Machinery. The eight industries reporting faster supplier deliveries in June — in the following order — are: Wood Products; Paper Products; Electrical Equipment, Appliances & Components; Fabricated Metal Products; Primary Metals; Plastics & Rubber Products; Computer & Electronic Products; and Transportation Equipment. Six industries reported no change in supplier deliveries in June as compared to May.

| Supplier Deliveries |

%Slower |

%Same |

%Faster |

Net |

Index |

| Jun 2024 |

8.8 |

82.0 |

9.2 |

-0.4 |

49.8 |

| May 2024 |

6.2 |

85.3 |

8.5 |

-2.3 |

48.9 |

| Apr 2024 |

8.1 |

81.6 |

10.3 |

-2.2 |

48.9 |

| Mar 2024 |

9.0 |

81.7 |

9.3 |

-0.3 |

49.9 |

Inventories

The Inventories Index registered 45.4 percent in June, down 2.5 percentage points compared to the reading of 47.9 percent reported in May. “Manufacturing inventories contracted at a faster rate compared to the previous month. None of the six big industries reported increased manufacturing inventories in June. Demand uncertainty is causing panelists’ companies to reduce investment in inventory and remain reliant on suppliers to carry ‘on-demand’ inventory,” says Fiore. An Inventories Index greater than 44.4 percent, over time, is generally consistent with expansion in the Bureau of Economic Analysis (BEA) figures on overall manufacturing inventories (in chained 2000 dollars).

Of 18 manufacturing industries, four reported higher inventories in June: Petroleum & Coal Products; Textile Mills; Electrical Equipment, Appliances & Components; and Primary Metals. The 10 industries reporting lower inventories in June — in the following order — are: Wood Products; Plastics & Rubber Products; Machinery; Miscellaneous Manufacturing; Nonmetallic Mineral Products; Furniture & Related Products; Computer & Electronic Products; Transportation Equipment; Food, Beverage & Tobacco Products; and Chemical Products.

| Inventories |

%Higher |

%Same |

%Lower |

Net |

Index |

| Jun 2024 |

11.3 |

67.9 |

20.8 |

-9.5 |

45.4 |

| May 2024 |

14.4 |

66.4 |

19.2 |

-4.8 |

47.9 |

| Apr 2024 |

13.1 |

67.7 |

19.2 |

-6.1 |

48.2 |

| Mar 2024 |

16.0 |

66.2 |

17.8 |

-1.8 |

48.2 |

Customers’ Inventories†

ISM®’s Customers’ Inventories Index registered 47.4 percent in June, down 0.9 percentage point compared to the 48.3 percent reported in May. “Customers’ inventory levels decreased at a faster rate in June, with the index moving downward in ‘about right’ territory. Panelists report their companies’ customers have decreased amounts of their products in inventory compared to the previous month, which is considered neutral for future new orders and production,” says Fiore.

The seven industries reporting customers’ inventories as too high in June, in order, are: Apparel, Leather & Allied Products; Textile Mills; Plastics & Rubber Products; Wood Products; Fabricated Metal Products; Transportation Equipment; and Computer & Electronic Products. The seven industries reporting customers’ inventories as too low in June, in order, are: Nonmetallic Mineral Products; Paper Products; Furniture & Related Products; Food, Beverage & Tobacco Products; Chemical Products; Primary Metals; and Machinery.

Customers’

Inventories |

%

Reporting |

%Too

High |

%About

Right |

%Too

Low |

Net |

Index |

| Jun 2024 |

78 |

13.6 |

67.5 |

18.9 |

-5.3 |

47.4 |

| May 2024 |

75 |

14.8 |

66.9 |

18.3 |

-3.5 |

48.3 |

| Apr 2024 |

76 |

15.6 |

64.3 |

20.1 |

-4.5 |

47.8 |

| Mar 2024 |

75 |

8.9 |

70.2 |

20.9 |

-12.0 |

44.0 |

Prices†

The ISM® Prices Index registered 52.1 percent, 4.9 percentage points lower compared to the May reading of 57 percent, indicating raw materials prices increased in June for the sixth month after eight consecutive months of decreases. Of the six largest manufacturing industries, three — Computer & Electronic Products; Food, Beverage & Tobacco Products; and Chemical Products — reported price increases in June. “The Prices Index indicated expansion in June, but at slower rate compared to the previous month. Commodity prices continue to be volatile, especially fuel, natural gas, aluminum and plastics. Steel prices are approaching long-term historical lows. Twenty percent of companies reported higher prices in June, compared to 26 percent in May, a clear improvement,” says Fiore. A Prices Index above 52.8 percent, over time, is generally consistent with an increase in the Bureau of Labor Statistics (BLS) Producer Price Index for Intermediate Materials.

In June, the eight industries that reported paying increased prices for raw materials, in order, are: Wood Products; Electrical Equipment, Appliances & Components; Textile Mills; Paper Products; Computer & Electronic Products; Food, Beverage & Tobacco Products; Miscellaneous Manufacturing; and Chemical Products. The three industries reporting paying decreased prices for raw materials in June are: Petroleum & Coal Products; Fabricated Metal Products; and Transportation Equipment. Seven industries reported no change in prices in June as compared to May.

| Prices |

%Higher |

%Same |

%Lower |

Net |

Index |

| Jun 2024 |

20.2 |

63.8 |

16.0 |

+4.2 |

52.1 |

| May 2024 |

25.5 |

63.0 |

11.5 |

+14.0 |

57.0 |

| Apr 2024 |

30.8 |

60.1 |

9.1 |

+21.7 |

60.9 |

| Mar 2024 |

23.6 |

64.4 |

12.0 |

+11.6 |

55.8 |

Backlog of Orders†

ISM®’s Backlog of Orders Index registered 41.7 percent, down 0.7 percentage point from the 42.4 percent reported in May, indicating order backlogs contracted for the 21st consecutive month after a 27-month period of expansion. The index recorded its lowest rate since November 2023, when it registered 39.3 percent. None of the six largest manufacturing industries reported expanded order backlogs in June. “The index remained in contraction in June, as new order rates were insufficient to allow backlogs to grow,” says Fiore.

Of the 18 manufacturing industries, the only one that reported growth in order backlogs in June is Primary Metals. The 14 industries reporting lower backlogs in June — in the following order — are: Electrical Equipment, Appliances & Components; Wood Products; Machinery; Nonmetallic Mineral Products; Textile Mills; Petroleum & Coal Products; Fabricated Metal Products; Paper Products; Food, Beverage & Tobacco Products; Computer & Electronic Products; Plastics & Rubber Products; Transportation Equipment; Chemical Products; and Miscellaneous Manufacturing.

Backlog of

Orders |

%

Reporting |

%Higher |

%Same |

%Lower |

Net |

Index |

| Jun 2024 |

90 |

10.7 |

61.9 |

27.4 |

-16.7 |

41.7 |

| May 2024 |

91 |

12.3 |

60.1 |

27.6 |

-15.3 |

42.4 |

| Apr 2024 |

90 |

12.2 |

66.4 |

21.4 |

-9.2 |

45.4 |

| Mar 2024 |

92 |

14.8 |

62.9 |

22.3 |

-7.5 |

46.3 |

New Export Orders†

ISM®’s New Export Orders Index registered 48.8 percent in June, down 1.8 percentage points from May’s reading of 50.6 percent. “The New Export Orders Index reading indicates that export orders contracted in June after expanding in May and contracting in April, with two straight months of expansion before that. New export levels remain sluggish as international trading partners continue to struggle with slow moving economies,” says Fiore.

The four industries reporting growth in new export orders in June are: Nonmetallic Mineral Products; Paper Products; Chemical Products; and Miscellaneous Manufacturing. The eight industries reporting a decrease in new export orders in June — in the following order — are: Fabricated Metal Products; Transportation Equipment; Primary Metals; Plastics & Rubber Products; Machinery; Food, Beverage & Tobacco Products; Electrical Equipment, Appliances & Components; and Computer & Electronic Products.

New Export

Orders |

%

Reporting |

%Higher |

%Same |

%Lower |

Net |

Index |

| Jun 2024 |

73 |

10.3 |

76.9 |

12.8 |

-2.5 |

48.8 |

| May 2024 |

72 |

10.0 |

81.1 |

8.9 |

+1.1 |

50.6 |

| Apr 2024 |

74 |

9.7 |

78.0 |

12.3 |

-2.6 |

48.7 |

| Mar 2024 |

76 |

12.2 |

78.8 |

9.0 |

+3.2 |

51.6 |

Imports†

ISM®’s Imports Index cooled in June with a reading of 48.5 percent, a decrease of 2.6 percentage points compared to May’s figure of 51.1 percent. “Imports contracted after five consecutive months of expansion preceded by 14 consecutive months of contraction. Respondents’ companies continue to limit investment in inventory, as future growth prospects remain cloudy. Ocean freight costs continue to rise and access to equipment remains restricted as a result of extended transit times, reducing available container and ship availability,” says Fiore.

The five industries reporting an increase in import volumes in June are: Primary Metals; Plastics & Rubber Products; Food, Beverage & Tobacco Products; Miscellaneous Manufacturing; and Chemical Products. The six industries that reported lower volumes of imports in June, in order, are: Wood Products; Nonmetallic Mineral Products; Transportation Equipment; Machinery; Computer & Electronic Products; and Fabricated Metal Products. Seven industries reported no change in imports in June as compared to May.

| Imports |

%

Reporting |

%Higher |

%Same |

%Lower |

Net |

Index |

| Jun 2024 |

83 |

8.7 |

79.6 |

11.7 |

-3.0 |

48.5 |

| May 2024 |

85 |

14.8 |

72.6 |

12.6 |

+2.2 |

51.1 |

| Apr 2024 |

85 |

11.6 |

80.6 |

7.8 |

+3.8 |

51.9 |

| Mar 2024 |

84 |

12.5 |

80.9 |

6.6 |

+5.9 |

53.0 |

†The Supplier Deliveries, Customers’ Inventories, Prices, Backlog of Orders, New Export Orders, and Imports indexes do not meet the accepted criteria for seasonal adjustments.

Buying Policy

The average commitment lead time for Capital Expenditures in June was 179 days, an increase of seven days compared to May. Average lead time in June for Production Materials was 80 days, the same as in May. Average lead time for Maintenance, Repair and Operating (MRO) Supplies was 43 days, a decrease of one day compared to May.

| Percent Reporting |

Capital

Expenditures |

Hand-to-

Mouth |

30 Days |

60 Days |

90 Days |

6 Months |

1 Year+ |

Average

Days |

| Jun 2024 |

14 |

3 |

11 |

14 |

28 |

30 |

179 |

| May 2024 |

15 |

3 |

9 |

15 |

32 |

26 |

172 |

| Apr 2024 |

17 |

4 |

8 |

13 |

32 |

26 |

170 |

| Mar 2024 |

14 |

5 |

9 |

13 |

31 |

28 |

176 |

|

| Percent Reporting |

Production

Materials |

Hand-to-

Mouth |

30 Days |

60 Days |

90 Days |

6 Months |

1 Year+ |

Average

Days |

| Jun 2024 |

8 |

24 |

27 |

28 |

9 |

4 |

80 |

| May 2024 |

6 |

26 |

31 |

23 |

10 |

4 |

80 |

| Apr 2024 |

7 |

23 |

29 |

30 |

7 |

4 |

79 |

| Mar 2024 |

8 |

22 |

31 |

28 |

7 |

4 |

78 |

|

| Percent Reporting |

| MRO Supplies |

Hand-to-

Mouth |

30 Days |

60 Days |

90 Days |

6 Months |

1 Year+ |

Average

Days |

| Jun 2024 |

29 |

36 |

16 |

14 |

5 |

0 |

43 |

| May 2024 |

29 |

38 |

15 |

13 |

4 |

1 |

44 |

| Apr 2024 |

29 |

37 |

17 |

12 |

4 |

1 |

44 |

| Mar 2024 |

25 |

40 |

18 |

12 |

5 |

0 |

44 |

Posted: July 1, 2024

Source: Institute for Supply Management

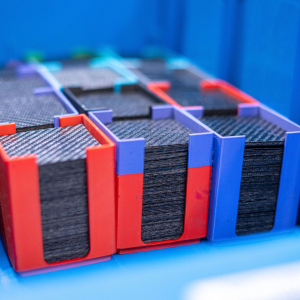

LENZING, Austria — July 3, 2024 — Lenzing Group, a leading global producer of wood-based specialty fibers, announces the launch of its latest Black Towel Collection made with LENZING™ ECOVERO™ branded black viscose fibers and TENCEL™ branded black modal fibers. The collection features six essential everyday washable and reusable face and body care items, from makeup removal pads, makeup removal towels, gym towels, bath towels, hand towels, hair bonnets, to beach towels, designed to cater to the ever-changing consumers’ needs for quality, responsible personal care items for every aspect of daily life. Made with ingredients that are responsibly produced1, the Black Towel Collection presents an alternative choice for a societal norm where conventional makeup removal products are mostly single-use disposable items, and reusable towels often get stained or discoloration due to repeated usage. The collection will bring about a refined experience to consumers through its exceptional durability, softness and color vibrancy.

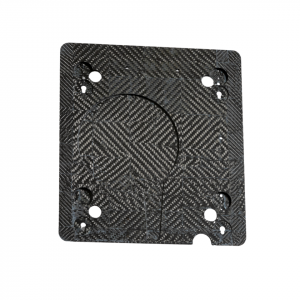

LENZING, Austria — July 3, 2024 — Lenzing Group, a leading global producer of wood-based specialty fibers, announces the launch of its latest Black Towel Collection made with LENZING™ ECOVERO™ branded black viscose fibers and TENCEL™ branded black modal fibers. The collection features six essential everyday washable and reusable face and body care items, from makeup removal pads, makeup removal towels, gym towels, bath towels, hand towels, hair bonnets, to beach towels, designed to cater to the ever-changing consumers’ needs for quality, responsible personal care items for every aspect of daily life. Made with ingredients that are responsibly produced1, the Black Towel Collection presents an alternative choice for a societal norm where conventional makeup removal products are mostly single-use disposable items, and reusable towels often get stained or discoloration due to repeated usage. The collection will bring about a refined experience to consumers through its exceptional durability, softness and color vibrancy. The Black Towel Collection is woven with a blend of cotton and TENCEL™ Modal black fibers or LENZING™ ECOVERO™ Viscose black fibers with a unique fabric composition to enhance durability. Even after multiple washes, these products retain their softness and gentle feel on the skin, making them ideal for repeated use. Derived from controlled or certified wood sources, these specialty fibers are made from resource-saving processes, using at least 50% less carbon emissions and water consumption1. Additionally, the LENZING™ ECOVERO™ Viscose black fibers are certified biodegradable and compostable at the end of their lifecycle2. Both reusable and responsibly produced, this towel collection is an excellent solution for individuals looking to minimize the carbon footprint1 of their everyday care practices.

The Black Towel Collection is woven with a blend of cotton and TENCEL™ Modal black fibers or LENZING™ ECOVERO™ Viscose black fibers with a unique fabric composition to enhance durability. Even after multiple washes, these products retain their softness and gentle feel on the skin, making them ideal for repeated use. Derived from controlled or certified wood sources, these specialty fibers are made from resource-saving processes, using at least 50% less carbon emissions and water consumption1. Additionally, the LENZING™ ECOVERO™ Viscose black fibers are certified biodegradable and compostable at the end of their lifecycle2. Both reusable and responsibly produced, this towel collection is an excellent solution for individuals looking to minimize the carbon footprint1 of their everyday care practices. Featuring a rich black color, the towels are dyed in the fiber stage using the spin-dyeing technique, where black color pigments are directly incorporated into the fibers. The unique process uses 50% less energy and water3 and does not require post-dye rinses, substantially enabling a 60% decrease in carbon footprint compared to conventional dyeing methods3. The process also helps preserve color intensity even after multiple washes4 and can mitigate the formation of cream spots caused by contact with substances like acne cream. With high colour fastness, consumers also do not have to worry about the black colour staining other garments in the washing process. Specifically, the gym towels and beach towels in this collection feature chlorine-resistant properties that minimize discoloration and fabric damage caused by exposure to chlorine in household water and swimming pools. This helps towels retain colour and quality longer, reducing the need for frequent replacement.

Featuring a rich black color, the towels are dyed in the fiber stage using the spin-dyeing technique, where black color pigments are directly incorporated into the fibers. The unique process uses 50% less energy and water3 and does not require post-dye rinses, substantially enabling a 60% decrease in carbon footprint compared to conventional dyeing methods3. The process also helps preserve color intensity even after multiple washes4 and can mitigate the formation of cream spots caused by contact with substances like acne cream. With high colour fastness, consumers also do not have to worry about the black colour staining other garments in the washing process. Specifically, the gym towels and beach towels in this collection feature chlorine-resistant properties that minimize discoloration and fabric damage caused by exposure to chlorine in household water and swimming pools. This helps towels retain colour and quality longer, reducing the need for frequent replacement.

“We are proud to work with Lenzing to develop our first Black Towel Collection. We have always loved experimenting with different fiber blends and fabric compositions to develop practical products that address the everyday needs of consumers. With this new offering, we hope that more brands and consumers will come to realize that they can be kinder to the world with small changes in their everyday habits,” said Mustafa Soylu, Research and Development Coordinator at Veritas Tekstil.

“We are proud to work with Lenzing to develop our first Black Towel Collection. We have always loved experimenting with different fiber blends and fabric compositions to develop practical products that address the everyday needs of consumers. With this new offering, we hope that more brands and consumers will come to realize that they can be kinder to the world with small changes in their everyday habits,” said Mustafa Soylu, Research and Development Coordinator at Veritas Tekstil.