From humble beginnings since the reunification of its northern and southern regions, Vietnam has

become a strong player in the global textile market. The textile and apparel industry plays a major

role in increasing the country’s prosperity. The Vietnamese textile industry, with more than 3,800

companies, is the leading export sector.

State-owned enterprises make up just 0.5 percent of Vietnam’s businesses; however, 75

percent are joint stock or limited companies. The country ranks fifth worldwide in textile and

apparel exports and has a labor force in that sector of more than 2 million people, of whom 1.3

million are working directly in the industry.

VINATEX

The Vietnam National Textile and Garment Group (VINATEX) is one of Asia’s leading textile

and apparel groups, and has a relationship with more than 400 organizations from 65 countries. It

was established in 1995 as a result of merging textile and apparel state-owned enterprises. Of its

120 members, 95 percent already have been equitized. VINATEX member companies account for 9 percent

of the Vietnamese textile and apparel industry’s total labor force and 18 percent of total exports.

Economy

Vietnam’s gross domestic product (GDP) grew by 5.9 percent in 2011, down from 6.8 percent in

2010. However, 2011 GDP growth was relatively high considering the country’s efforts to control

inflation.

Vietnam’s textile and apparel exports in 2011 totaled US$15.8 billion, up 24.4 percent

compared to 2010. Its main export markets were the United States, which accounted for $6.9 billion

of those exports; the European Union, $2.5 billion; and Japan, $1.7 billion. Of the total textile

and apparel exports, yarn exports accounted for $1.79 billion — up 27.8 percent from the previous

year. China accounted for 30.5 percent of yarn exports; Korea, 16.1 percent; and Turkey, 15.4

percent. Vietnam’s fabric exports totaled $831.7 million.

Vietnamese textile and apparel exports continued to record growth in the first six months of

2012, growing by $7.7 billion — an 8.2-percent increase over the same period in 2011.

In 2011, textile imports, not including accessories, netted $9.3 billion — a 28.8-percent

increase over 2010 imports worth $7.2 billion. Cotton imports totaled 332,600 metric tons (mt)

valued at $1.05 billion. Imports of other fibers and yarns totaled 614,100 mt and were worth $1.53

billion. Fabric imports totaled approximately $6.7 billion.

Structure

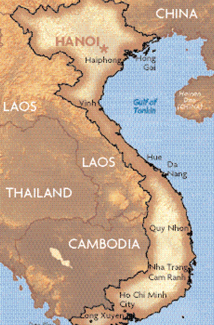

There are 70 spinning companies in Vietnam, 31 of which are located in northern Vietnam, six

in the middle region and 33 in the south.

At the end of 2011, the textile sector employed some 840,000 people — 11.2-percent more than in

2010. The average hourly wage for textile workers that year was 60 cents in U.S. currency terms.

Important Retail Business

The cornerstone of the Vietnamese textile industry is basically the retail business. The

country has 71 textile/apparel supermarkets, with locations in 25 cities and provinces. Plans call

for increasing that number to 200 supermarket and trade centers nationwide by 2015, and to

establish textile and apparel material and accessories centers in northern and southern Vietnam.

Plans are also in place to promote and enhance fashion brands to increase competitive strengths,

and to create an online textile/apparel trade website.

The Vietnamese textile and apparel industry’s customers include the top labels worldwide. To

name a few from the top three markets, U.S. brands and retailers include, among others, JCPenney,

Nike Inc., Gap Inc., PVH Corp., Liz Claiborne, Target Brands Inc. and Perry Ellis; European brands

and retailers include Marks & Spencer, C&A, The Otto Group, Camel, Seidensticker, Pierre

Cardin and Jacques Britt; and Japanese brands and retailers include Itochu Corp., Sojitz Corp.,

Marubeni Corp., Mitsui & Co. Ltd., Seikyo, Mitsukoshi Ltd. and Katakura Industries.

Capacities

Vietnam consumes some 400,000 mt of cotton annually — with 35 percent of that total imported

from the United States, 32 percent from India and 19 percent from South Africa.

In 2010, 3,656,756 ring spindles and 104,348 rotors were installed in Vietnam. Total yarn

production capacity was 514,000 mt per year, primarily for 100-percent cotton yarn. Domestic

consumption accounted for 34.7 percent of the yarn produced. Woven fabric capacity in 2010 was 680

million square meters (m2). The available production capacities and imports of these and other

textile products are shown in Table 2.

Investment Opportunities

Investment projects, along with government incentives for foreign investment, are deemed to

be central to the improvement of the Vietnamese textile and apparel industry as Vietnam seeks to

strengthen its competitive position in global apparel markets. Other contributing factors include

low labor costs and a stable political environment.

The Vietnamese textile industry today comprises mainly apparel cut-and-sew enterprises.

VINATEX has the following investments in the works to build manufacturing capacity for upstream

textile production:

- viscose fiber plant (phase one): 30,000 mt/year capacity;

- compact spinning mill with 60,000 spindles: 4,500 mt/year capacity;

- greige fabrics plant: 30 million running meters/year capacity; and

- dyeing plant: 30 million running meters/year capacity.

Human Resources

VINATEX is focusing on R&D and training to foster competitiveness. There are plans for

the long-term development of vocational schools and colleges. In this context, 20,000 workers

should receive training to reach intermediate, college, or higher skill levels. There also is a

plan to add some 60,000 educated and skilled workers every year. And, finally, the textile industry

wants to cooperate with international partners to provide high-quality training.

Future Plans

The Vietnamese textile and apparel industry has an ambitious target plan, with investment

capital estimated to total approximately $25 billion in 2020 (See Table 3). A complete

infrastructure is planned for the industrial areas, including traffic systems, power and water

supply, drainage and wastewater treatment centers.

The current textile and garment industrial total area of 510 hectares (ha) is based in two

regions: in the north, in Pho Noi B comprising 121 ha and Bao Minh comprising 165 ha; and in the

south, in Binh An comprising 76 ha and VINATEX Tan Tao comprising 148 ha. There is an ambitious

plan to further extend the industrial area for textiles and garment production by 1,080 ha.

Bright Future

The future of the Vietnamese textile industry looks bright because of continuous efforts

made by textile companies to upgrade their equipment to enhance their competitiveness. Over the

last three years, there has been a fundamental change in the industry’s structure, especially in

the spinning subsector.

Vietnamese Textile Industry Self Evaluation

In collaboration with VINATEX, the Vietnamese textile industry evaluated its own strengths

and weaknesses in a SWOT analysis. A SWOT analysis is a strategic planning method to evaluate the

strengths, weaknesses/limitations, opportunities and threats involved in a business or project.

Here is the outcome of the analysis:

Strengths

- Dominant exporting capability and highly potential domestic market;

- Low costs, skillful labor force;

- Renovated and modernized equipment;

- Stable political environment; and

- Incentive policies.

Weaknesses

- Most enterprises are medium and small size;

- 50 percent of raw materials are imported;

- Production management is still weak and inefficient; and

- Marketing strategy is not paid serious attention.

Opportunities

- Shifting trend from China to Association of Southeast Asian Nations (ASEAN) countries,

including Vietnam;

- Attracting investors from potential markets such as Russia and Korea;

- Expanding market share in United States, European Union and Japan market; and

- Large population: 86 million people.

Threats

- Strong competition from rivals including China, India and Indonesia; and

- Bargains of technology, hygiene, social responsibilities.

Competitive Advantages

However, VINATEX has defined some important competitive advantages over its neighboring

states, such as:

- Abundant source of skillful, fast-learning and wage-competitive labor;

- Modern facilities backed with high-quality water treatment systems;

- Cost-competitive locations for manufacturing and exporting;

- Good and strong relationships with big international buyers/importers;

- Recognition of credibility for high-quality products; and

- Support from free trade agreements with major exporting markets.

Source: VINATEX

September/October 2012