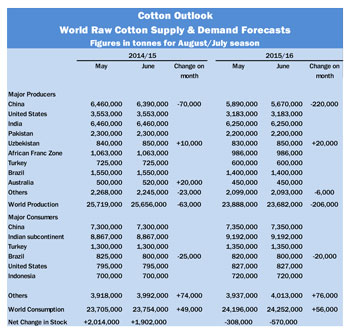

WASHINGTON — July 1, 2015 — In 2014-15, the Secretariat predicts a midpoint of 71 cents/lb for the Cotlook A Index with a narrow range of 70 to 73 cents/lb. In 2015-16, international cotton prices may remain stable, though this will depend in part on changes in world cotton stocks. In 2014-15, world ending stocks are forecast up 9 percent to 21.9 million tons, reflecting a stock-to-use ratio of 90 percent. Starting in 2010-11, the world has accumulated 13.4 million tons of stock due to production volumes exceeding consumption volumes. In 2015-16, stocks are projected to decrease 5 percent to 20.9 million tons, reducing the excess volume by 1 million tons. Stocks held outside of China are expected to decrease by 3 percent, to just under 9 million tons, by the end of 2015-16. However, much of this will depend on how the Chinese government handles its reserves. Last month the Chinese government announced that it planned to start selling its stockpiles, estimated at around 11.3 million tons, at a price close to the current market price in the hopes of keeping the market stable. However, no further details have been announced so far, and it’s uncertain how successfully China will be able to sell off its excess cotton stock without destabilizing the market.

World cotton area in 2015-16 is projected down 6 percent to 31.3 million hectares, due largely to lower prices in 2014-15. Assuming a world average yield of 764 kg/ha, production could reach 23.9 million tons, down 9 percent from 2014-15. China’s cotton area is forecast to decrease by 12 percent to 3.8 million hectares, and production down by 16 percent to 5.4 million tons in 2015-16. While low cotton prices during 2014-15 in India are expected to cause cotton area to decrease by 5 percent to 11.6 million hectares in 2015-16, falling prices for competing crops and a modest increase in the minimum support price may forestall a greater decline. The Indian monsoon arrived earlier this year compared to 2014-15, and yields may improve 3 percent to 547 kg/ha, limiting the decrease in production to 6.4 million tons. Low international cotton prices have limited farmer enthusiasm to plant cotton, and area in the United States may contract 15 percent to 3.3 million hectares.

Production is forecast to decline by 12 percent to 3.1 million tons. Area in Pakistan is projected to contract 6 percent to 2.7 million hectares due to low domestic prices in 2014-15, and production is expected to decrease 11 percent to 2.1 million tons.

In 2015-16, world cotton consumption is forecast up 2 percent to 24.9 million tons. China’s consumption is expected to remain stable at 7.7 million tons, though its share of total world consumption will likely decline to 31 percent, which is the sixth consecutive season of reduction since 2009-10 when it accounted for 40 percent of world consumption. India’s mill use is projected up 3 percent to 5.4 million tons in 2015-16, accounting for 22 percent of world consumption. Strong demand from countries that rely on imports to support their spinning sector is expected to boost world trade in 2015-16 to 7.7 million tons. Imports outside of China are projected up 4 percent to 6.1 million tons, partially offsetting the 9 percent decline in Chinese imports to 1.6 million tons.

World Cotton Supply And Distribution

| 2013-14 | 2014-15 | 2015-16 | 2013-14 | 2014-15 | 2015-16 | |

| Changes from previous month |

||||||

| Million Tons | Million Tons | |||||

| Production | 26.28 | 26.20 | 23.92 | -0.01 | 0.03 | 0.02 |

| Consumption | 23.75 | 24.36 | 24.91 | -0.01 | 0.00 | -0.02 |

| Imports | 8.65 | 7.64 | 7.74 | -0.02 | 0.12 | 0.06 |

| Exports | 8.87 | 7.64 | 7.74 | -0.01 | 0.12 | 0.06 |

| Ending Stocks | 20.04 | 21.89 | 20.90 | 0.04 | 0.07 | 0.11 |

| Cotlook A Index | 91 | 71* | 72** |

*The price projection for 2014-15 is based on the ending stocks/mill use ratio in the world-less-China in 2012-13 (estimate), in 2013-14 (estimate) and 2014-15 (projection), on the ratio of Chinese net imports to world imports in 2013-14 (estimate) and 2014-15 (projection). The price projection is the midpoint of the 95 percent confidence interval: 70 cts/lb to 73 cts/lb.

**The price projection for 2015-16 is based on the ending stocks to mill use ratio in the world-less-China in 2013-14 (estimate), 2014-15 (projection) and 2015-16 (projection), on the ratio of Chinese net imports to world imports in 2015-16 (projection), and on the price projection for 2014-15. The price forecast for 2015-16 is the mid-point of the 95 percent confidence interval: 57 cts/lb. to 87 cts/lb.

Posted July 7, 2015

Source: ICAC