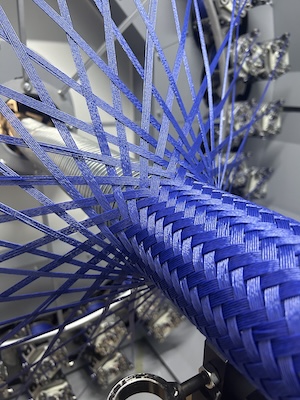

ALBSTADT, Germany — July 31, 2025 — At the end of July 2025, the Albstadt-based braiding machine manufacturer Mayer & Cie. delivered its first MR-15 braiding machine with 48 carriers. An MR-11 system, also equipped with 48 coil carriers, left the plant before Christmas 2024 and has since reached the customer. The business unit has been part of the headquarters in Albstadt since 2019. Ongoing development has enabled Mayer & Cie. braiding to solidify its market position while evolving from a “little brother” into a key pillar of the company.

ALBSTADT, Germany — July 31, 2025 — At the end of July 2025, the Albstadt-based braiding machine manufacturer Mayer & Cie. delivered its first MR-15 braiding machine with 48 carriers. An MR-11 system, also equipped with 48 coil carriers, left the plant before Christmas 2024 and has since reached the customer. The business unit has been part of the headquarters in Albstadt since 2019. Ongoing development has enabled Mayer & Cie. braiding to solidify its market position while evolving from a “little brother” into a key pillar of the company.

“We are pleased that we have now also completed an MR-15 with 48 carriers,” said Patrick Moser, head of the business unit about the braiding line with two decks. “This shows that we have fully achieved our goal of strengthening in-house development in the field of braiding machines.”

Mayer & Cie. Braiding – a “company within a company” with a clear course

The Mayer & Cie. Braiding division has been based in Albstadt since 2019. “We are a company within the company, an independent division within a larger construct,” Moser explained. In production, Mayer & Cie. works with the same process landscape, for circular knitting machines as well as for braiding machines. “The products have nothing in common with each other, but the process in the house is still the same. That’s highly efficient.”

Despite the structural similarities, the markets differ significantly: While Mayer & Cie. sells circular knitting machines in around 80 countries through local representatives, the braiding sector usually operates directly. The braiding division only works with local representative offices in selected markets – for example, if there is a certain market volume or cultural or linguistic aspects make direct sales difficult. In exceptional cases, such as in India, both divisions share a representation.

The largest market for braiding machines is China, where more than 50 percent of the hydraulic hoses manufactured worldwide are produced. The USA and Italy are also large markets. “In itself, our business is rather project-driven,” Moser added. “Where such a project is realized geographically is of secondary importance.”

Technological development with roots in Albstadt

Since moving from the United States to Albstadt, Mayer & Cie. has been consistently pushing ahead with the further development of its braiding technology. Even during the transfer, processes and components were re-evaluated, documented and optimized. “Every step and every part was put on the table,” recalls Moser, who set up a new production line together with his team in Albstadt.

One of the central innovations: the servo drive, which can be used to control each deck individually.

The soundproof booth was also redesigned — among other things, because new supply chains had to be established. At ITMA 2023, the company unveiled another innovation: the SpeedBooster — a solution designed to significantly enhance machine speed and overall productivity

For Moser, innovation is a central component of the corporate culture: “I really appreciate the short distances and quick decisions at Mayer & Cie.,” says the experienced technician, who has been responsible for the business unit since 2018. The Albstadt-based company also relies on modern processes in production: While induction hardening is used in the circular knitting area, dynamic simulation is used in the braiding area — a decisive basis for the successful implementation of the 48-carrier machines.

Larger hose diameters, longer running times

inches).

Braiding machines with 48 carriers are the latest of the braiding machine developments. This allows users to expand their range of hose inner diameters, which now range from 50 millimeters (2 inches) to 150 millimeters (6 inches).

The volume of spools with which the braiding machine is equipped remains the same — even if their absolute number increases to 48. For users, the combination means that they can process more material before a coil change is due.

Growth area with prospects

The positive development of the business unit makes the division manager optimistic: “We are seeing an increasing number of inquiries for interlinked systems and in-line processes in which further units are to be integrated into the braiding line,” says Moser. In addition, an expansion of the portfolio to include other machine types is conceivable.

Posted: August 1, 2025

Source: Mayer & Cie. (MCT)