Gore To EstablishOperations In ChinaIn an effort to expand the companys manufacturing capabilities,

W.L. GoreandAssociates Inc., Newark, Del., will establish a fabrics-manufacturing operation in

China.The new facility, located near Hong Kong, will begin production of Gore-Tex® fabrics for both

the regional and export markets in 2003. Thirty to 50 positions are expected to be filled by the

end of 2002.Asia has emerged as a formidable textile supply and innovation center, said Terri

Kelly, fabrics business leader. This region also presents significant market opportunities. We are

very excited about the global supply chain flexibility and international market potential that

operations on three continents will provide.The company has operations in Europe, North America and

the Asia Pacific region.

July 2002

Gore To Establish Operations In China

Tweave Offers New Stretch Woven Fabrics For Intimates

Tweave Offers NewStretch Woven Fabrics For IntimatesTweave Inc., Norton, Mass., has added two new styles, 528 and 529, to its Durastretch® line of stretch woven fabrics for intimate apparel. Tweave claims woven constructions allow spandex to move more freely, providing superior recovery and memory, as well as improved fit and contouring with less bulk, when compared with knit constructions.July 2002

DuPont Ink Jet Ichinose Offer Digital Printing System

DuPont Ink Jet, IchinoseOffer Digital Printing SystemWilmington, Del.-based DuPont Ink Jet and Japan-based Ichinose Toshin Kogyo Co. Ltd. presented a new digital textile printing system at the Japan International Apparel Machinery 2002 Trade Show. It is the first fully integrated, production-capable, digital textile printing solution for the apparel industry, according to the companies.DuPonts Artistri Color Control and Management System software allows designs of all types to be printed directly from the computer, while the Artistri 700 Ink Series is available in shades for reactive dye, acid dye, and disperse dye and pigment.The Ichinose 2020 roll-to-roll printing system is equipped with fabric transport technology that allows printing on wovens and knits, including stretch fabrics. The system will be commercially available in the fall.July 2002

It39 S In The Jeans

By Virginia S. Borland, New York Correspondent It’s In The JeansMeeting market demands and fashion needs, manufacturers are developing denim using new fiber blends, weights and finishes. From workwear to business attire, denim is the fabric of choice. Its in almost everything pants, skirts, dresses, jackets, accessories, even eveningwear and products for the home.The phenomenal growth of denim has been gradual and global, and does not appear to have reached its peak. What is new is the variety of denim fabrics in the marketplace. Just when you think nothing else can happen to denim, it turns up in new weights and fiber blends, with new finishes and application treatments.The French lay claim to inventing denim and believe the word is an English adaptation of “serge de Nimes,” a fabric woven in the French city of Nimes in the 16th century.Italy takes responsibility for the creation of jeans, a word derived from Genoese and referring to cotton twill trousers worn by sailors in Genoa. The popularity of denim jeans started in the l9th century in America with Levi Strauss.

Denim made from Irish linen and Lycra® offers stretch properties, easy care and a soft hand, according to Masters of Linen. Denim Is AuthenticKeith Hull, president, Marketing and Sales, Avondale Mills, Monroe, Ga., said, Denim is popular because it is comfortable, it looks good and it is versatile. Part of its current success is a reaction to 9/11 and a direction to back-to-basics. Denim is authentic.John Heldrich, president and CEO, Swift Denim, Columbus, Ga., agrees: Denim is a cradle-to-grave product. It is the best and most versatile global fabric. It can take on so many different looks through yarns, construction and laundering.Mike Moody, executive vice president and general product manager, cotton apparel, Burlington WorldWide Ltd., Greensboro, N.C., attributes denims popularity to casual dress in the workplace. Denim is both fashion- and performance-driven, he said.Universally, denim weavers agree that the core business is the five pocket jean, made in 10- to 12-ounce 100-percent cotton that is ring-spun and indigo-dyed. Approximately two-thirds of all denim apparel purchased in 2001 was jeanswear.Basic denim is always there, said Livingston, but today it has many different characteristics and different touches.Denim mills are sold up well into the third quarter of the year. Today, our biggest problem, said Hull, is meeting the demand.Avondale weaves between 80 and 100 different denim fabrics. Darker blue shades are popular; black has become a staple. There are softer finishes, shiny surfaces and flatter looks. Even rigid denim has a soft touch, said Hull.Avondale works in partnership with its customers to develop special looks. Currently, the direction is to lighter weights, softer finishes and casts of indigo. Some of the popular jeans cuts include cargos, low rises and carpenters. Other apparel categories include skirts and jackets. Other end-uses include curtains and slipcovers. Jack Mathews, vice president, fabric sales and marketing, American Cotton Growers (ACG), Littlefield, Texas, said, Denim is in a strong fashion cycle. The basics are selling, but fashion denims that have texture and character are what is in demand. Some of the new garment washes and finishes are also helping to drive this business.Other factors Mathews cited for the renewed popularity of denim are low retail inventories after Christmas and mill closings.

Denim eveningwear designed by Christian David Kozaki for Les Belles Choses. Photograph courtesy of Cotton Incorporated. ACGs business is focused on jeanswear. Most of the line is 100-percent cotton, open-end, faux ring-spun and ring-spun denims. All fabrics are indigo-dyed. Mathews noted a new blue/black shade called Raven is popular. New styles containing Lycra® are in development. Mathews sees denim sales continuing strongly through the end of the year, with no slowdown in sight until the first quarter of 2003. The biggest challenge is to get the price up, he said. In bad times, prices fall in quarters; in good times, they go up by nickels. Service And Price Drive The BusinessService and price are what drive the business, said Monte Galbraith, vice president, sales and marketing, Denim North America (DNA), Columbus, Ga. We will never be the lowest price, but we do offer the best service. What the domestic market has going for it is proximity and speed to market. We can work with customers on a daily basis to develop new products.DNA came on-line May 1, taking over Marubenis state-of-the-art four-year-old plant (See News, TW, this issue). The bulk of its production is ring-spun cotton denim in the 10- to 12-ounce range. Fabrics can go as light as 7 ounces.With fashion silhouettes cleaning up and becoming sleeker, Galbraith said there is a lot of talk about color, but all casts of blue will always be available. A black shade called Asphalt is selling in every construction. In addition to all-cotton, DNA is weaving cotton/Lycra and cotton/polyester, and is developing a variety of stretch products.Ring-spuns, stretch and lighter weights are popular at Swift. Customers are still looking for denims with a vintage-look, flat and worn appearance, Heldrich said. Our basic Hard Core Blues continues to be a best seller.Along with apparel, Swift denims are in comforters, belts, hats, log carriers and dog beds. Denim will always be in fashion, Heldrich said. Sometimes the fashion cycle is stronger. As long as we focus on being innovative and provide good value around the world, we will continue to be successful.” S-t-r-e-t-c-hAlthough the majority of Burlingtons line is 100-percent cotton, stretch denim is one of the fastest-growing segments of its business. The company is weaving blends with both Lycra and DuPonts T-400. Polyester blends are there for strength. Moody also mentioned that black denim is having a resurgence.He also noted that most of Burlingtons customers are using more sophisticated wet processing such as sand-blasting. Sometimes a garment will go through several different treatments. Burlington is working on new technologies to give denim fabrics different looks when processed.At Cone Mills, Kara Nicholas, director, new product development, specialty stores, said, We have developed a lot of new blue shades. We are getting a good reaction to some of the clear blues and lighter colors.Were past the idea of basic denim, she continued. As long as we innovate and keep coming out with something new, we will find a fashion customer. Stretch is one area of innovation. Cone is developing lighter-weight, stretch denim fabrics with spandex and with polyester for comfort stretch. The company also is experimenting with new cotton yarns to give different looks to denim. Stretch denim has been popular in Europe for more than a decade. In the United States, it is selling strongly in juniors and is beginning to be accepted by other age, gender and ethnic groups. According to Livingston, stretch is adding another dimension: it provides comfort, shape and fit. Cotton Incorporated is working on development of 100-percent cotton stretch denim by using finishes and treatments.

Eddie Bauer Home is using denim for home furnishings.Photograph courtesy of Cotton Incorporated. Most of the stretch denim sold in the world today contains an elastomeric fiber. DuPont Textiles and Interiors (DTI) is promoting stretch denim containing Lycra at high-fashion and mass-market levels, from Armani to Levis. Recently, DuPont participated in New Yorks Fashion Week in a joint show featuring stretch denim apparel created by six designers/brands.Another DuPont product that can provide comfort stretch to denim is T-400. It is chlorine-resistant and can withstand a variety of bleaching and washing conditions such as sandblasting, whisker washing and antique finishes. For more tailored looks, T-400 will retain trouser creases after washing.In partnership with Velonorte Mills of Brazil, DuPont has created a knitted stretch denim called Veloflex®. Containing 96-percent cotton and 4-percent Lycra, Veloflex denim has been sampled by designers such as Theory, BCBG, DDC Lab, Hippie Jeans, Adriano Goldschmied and Melanie Apple. The fabric has a soft hand, is supple and enables designers to create slim-cut jeans that provide comfort and freedom of movement. Linen And BlendsAlso jumping onto the bandwagon, European linen weavers have developed denim fabrics in a variety of looks and weights. According to Pauline Delli-Carpini, U.S. representative, Masters of Linen, denim woven of linen can be clean, structured and elegant; or rustic and casual. She cites shades of dark cobalt blue and graphite as popular.There are rigid linen denims, cotton blends and stretch with Lycra. The trend is to lighter weights and faded, antique finishes that have an elegant look. All of the linen-content denims are easy-care, and many are pre-washed to give the fabrics a soft hand.In addition to apparel, Delli-Carpini noted that denims of linen are widely used in fabrics for the home. Because of its antistatic properties, linen doesnt attract dust or dirt, so it is especially popular for upholstery, slipcover and drapery fabrics.A lot of European mills are showing denim fabrics and the look of denim with application treatments and embellishments. There are flocked, embroidered and coated surfaces; reversibles; sheers that are printed to look like denim; indigo-dyed jacquards knitted or woven using linen and cotton; laser cut-outs on denim; puckers; matte/sheen patterns; and the ultimate denim-patterned sequins applied to lace (See Premiere Vision Predictions, TW, May 2002). Tencel®Another fiber that is widely used in denim is Tencel®. June Lauck, marketing communications manager, Tencel, said the Belgian firm UCO and Tejidos Royo of Spain are selling Tencel-content denim fabrics. UCO denims are woven using dyed Tencel in the warp, and they have a uniquely soft and silky touch.Lauck pointed out that two reasons for Tencels popularity in denim are its aesthetics and performance. Because of its strength, Tencel can withstand harsh bleaches, acid washes and finishing treatments, even in lightweight constructions.Denim fabrics containing Tencel have a clean, neat look and natural luster. High levels of stretch can be achieved without the use of elastomeric fibers because of Tencels unique fiber-swelling properties.Enrique Silla of the Spanish firm Jeanologia has created jeans, jackets, skirts and other apparel in Tencel-content denim. Some of the newest looks shown at his most recent presentation were whitened or tinted blue shades. Some had gray or yellow casts. Most of the apparel has movement and excellent stretch and recovery.Will the denim momentum continue Mills are sold up through the third quarter, and denim producers are continuing to come out with new and relevant products. As Galbraith said, At DNA, denim is in our genes.June 2002

Contech Presents New Slitter-Sheeter System

Contech PresentsNew Slitter/Sheeter SystemContech, Goddard, Kan., offers a new roll-fed slitter/sheeter system that uses a shaftless unwind to permit quick changes of rolls of material weighing up to 8,000 pounds.After slitting, the material is gathered through controlled gravity loops that restrict material stretch and cut using a gap shear cutter. The sheets are then grabbed and stacked using a gripper stacker. July 2002

Melco Introduces Amaya Embroidery System

Melco IntroducesAmaya Embroidery System

Melco Embroidery Systems, Denver, a wholly owned subsidiary of Saurer Ltd., Switzerland, reports its Amaya embroidery machines are the first to provide modular capabilities. Amaya offers flexible configuration of up to 30 heads, with the possibility of operating multiple units simultaneously from one PC computer.Other features include automatic Acti-Feed Thread Tensioning, consistently high speeds of up to 1,500 stitches per minute, 16 needles per head, laser tracking, a built-in tutorial system, adjustable pressure foot, new safety grabber and more.July 2002

I N C Materials Installs Struto Releases Deci-Tex

I.N.C. Materials InstallsStruto®, Releases Deci-TexAustralia-based I.N.C. Engineered Materials recently added Struto® vertical lapped nonwoven fiber technology to its existing lamination and adhesive backings equipment.Following research and development efforts using the new equipment, I.N.C. has introduced its new Deci-Tex 3D materials. Selected for use by three Australian car makers, Deci-Tex offers 50 percent higher sound absorption and is 75 percent lighter than traditional felts used by auto makers, according to I.N.C. The Struto technology was developed by a company in the Czech Republic and is available in the United States through Dalton, Ga.-based Georgia Textile Machinery.June 2002

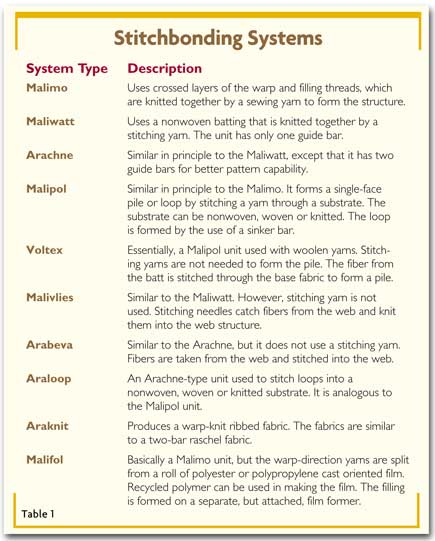

Textiles In Stitches

By Richard G. Mansfield, Technical Editor Textiles In StitchesStitchbonding is finding its niche after years of trial and error. Stitchbonding is a hybrid technology using elements of nonwoven, sewing and knitting processes to produce a wide range of fabrics that are used in home furnishings and industrial fabrics, including composite structural applications. The versatility of stitchbonding can best be understood by reviewing the types of stitchbonding processes (See Table 1).The initial work on stitchbonding took place in Czechoslovakia and East Germany during the 1960s using short-staple fibers to produce fabrics for industrial and utilitarian non-styled household uses. These fabrics were made using creel-fed, spun stitching yarns. As the use of stitchbonding spread to the United Kingdom and other countries, nylon and polyester filament yarns became the preferred materials for the stitching component. Malimo Stitchbonding SystemsThe Mali system of stitchbonding was initiated during the late 1940s by Heinrich Mauersberger of East Germany. His U.S. Patent #2,890,579 was issued on June 16, 1959. Mauersbergers first fabrics were based on joining warp and filling yarns with a stitching yarn to produce a woven-like fabric. The first product produced by the Malimo stitchbonding process was a toweling, made in 1952. To introduce the Malimo machine in the United States, the East German manufacturer appointed Klauss Bahlo to be its manufacturers representative in the United States. When CromptonandKnowles Co. took a license from the East German manufacturer of the Malimo around 1962, Bahlo became a vice president with the company. CromptonandKnowles imported a number of machines to the United States.

Karl Mayer’s Malimo machine is used for the stitchbonding of multi-layer reinforcement fabrics for the composite industry. The first two Malimo units went to Guilford Woolen Mills in Guilford, Maine. Guilford was then run by King Cummings. The companys initial efforts with the Malimo machine were concerned with the use of woolen yarn. By mid-1963, Cummings decided to sell development time on the companys Malimo machines to other textile companies, rather than trying to develop fabrics for Guilford. Indian Head Co. became interested in the Malimo machine and ran extensive trials on the machinery at Guilford. Indian Heads decision to put the Malimo in a knitting plant was based on its experience gained from using the machines at Guilford.In March 1963, Indian Head ordered two Malimo units at a price of $45,000 per machine. Four months later, Indian Head set up the first Malimo machine at its Native Lace Co. plant in Glen Falls, N.Y. Dan Duhl, who later was to become president of the Polylok Corp., was appointed product development manager for the Malimo program in April 1964.Initial trials by Indian Head with the Malimo used a range of materials including mohair, worsted and cotton novelty yarns. A considerable number of mechanical problems were encountered with the early Malimo machines. Fabric problems included curling selvages, side-to-side nonuniformity and mending problems.As development work at Indian Head progressed with the Malimo fabrics, home furnishings fabrics were recognized as having good potential. The first production order by Indian Head was a drapery fabric using a preshrunk polyester stitching yarn combining a random warp of cotton and a filling of natural and yarn-dyed cotton and rayon. Another drapery fabric produced by Indian Head was a fabric known as Fiberglo. This fabric was made of modacrylic, rayon and polyester fibers and had excellent flame-resistant properties.A number of promising fabrics for casements, draperies, reinforced industrial fabrics and coating substrates were developed by Indian Head from the start of its program in 1963 until its termination in 1973. One of these fabrics was a cold-weather apparel fabric called Thermal-Dermal made by stitching yarn into polyurethane foam.Indian Head, as a $400-million conglomerate, did not want to absorb further losses on the Malimo program. The establishment of the Polylok Corp. by Duhl provided a good mechanism for Indian Head to terminate the project. The machinery was sold under very favorable terms to Polylok, which allowed Duhl to start a business with a relatively small initial capital outlay. Other Mills That Worked With The MalimoBurlington Industries, Greensboro, N.C., put a considerable amount of effort into the Malimo system over about a four-year period. It established a separate Nexus Division for the Malimo program, developing a number of casement and drapery fabrics. A line of tablecloths was developed and marketed through Sears and other chain stores. Burlington unsuccessfully tried to develop womens- and menswear fabrics with the Malimo. The womenswear fabrics were based on woolen spun yarns, and the menswear fabrics used worsted yarns. One of the major shortcomings of the Malimo fabrics for apparel use was their lack of recovery when deformed; garments would bag at the elbows and knees.In early 1969, Burlington announced the division was closing, and activities with the Malimo machines were terminated. Both J.P. Stevens and M. Lowenstein also were unsuccessful in their efforts to develop apparel fabrics using the Malimo machine. Reeves Brothers was interested in Malimo fabrics because of their high tear strength and dimensional stability. However, in comparing the Malimo substrates to woven fabrics for coatings, at that time it found that no cost savings were obtained with the Malimo fabrics.Libbey Manufacturing in Lewiston, Maine, under the direction of President Paul Libbey, entered the stitchbonding business in the late 1960s using Malimo and Maliwatt machines. Libbey produced Malimo casement fabrics for the home decorating trade, and industrial glove and shoe linings using Maliwatt equipment.

Why Did Malimo Have Only Limited Success In The U.S.Stitchbonded nonwovens gained acceptance in Europe, particularly in the Soviet-dominated Eastern-Bloc countries, where fabric aesthetics were not a major concern. Later, acceptance of stitchbonding grew gradually in Western Europe for specialty fabrics. By 1984, there were more than 1,000 machines producing more than a billion yards of fabric per year. Most of these machines were producing industrial fabrics.The Malimo achieved success in home furnishings and domestics in the United States, where the unique appearance of the fabrics was a virtue. Included were fabrics for casements, draperies and tablecloths. In industrial fabrics, the Malimo has been used successfully to make substrates for coated abrasives and in conveyor-belt applications in which extreme dimensional stability is important. Polylok, Tietex and Superior Fabrics were able to develop Malimo fabrics for vertical blind louvers.A major factor in the disenchantment with the Malimo was that it was oversold to the textile industry as a high-speed replacement for the loom. Raw materials for fabrics produced using the Malimo cost as much as or more than raw materials used for woven fabrics, because a three-yarn system is used and the quality of the stitching yarn is very important. Direct costs for the Malimo are higher than weaving because one worker can attend only about five machines, while a worker can attend more than 100 looms. The stitchbond machines produced in the Soviet-Bloc countries suffered from lack of quality control in their manufacture and required extensive maintenance work to keep them running Tietex Co.Tietex Co., Spartanburg, is the most successful stitchbonded nonwovens company in the United States and the worlds largest producer of stitchbonded fabrics. In addition to Malimo machines, Tietex has Liba stitchbonding machines. The company was started in 1972 by Arno Wildeman. Wildeman had been associated with Cosmopolitan Textiles of England, a producer of stitchbonded fabrics used for printed drapery and bedspreads. Wildeman developed techniques for modifying the machines he purchased to make them more reliable and versatile. One of his patented developments was a method of locking in the tricot stitching in a Maliwatt-type machine by tying in the stitching yarn to the fleece fibers.Tietex diversified its product line and soon added mattress ticking and flexographic printing. Tietex is believed to be the only major company using flexographic printing for textiles. Up to eight colors can be applied on this unit. One of the major advantages of flexographic printing is that it requires less dyestuff to produce a shade than it would to print the same pattern and shade using rotary screen printing or roller printing.The company has developed techniques for foam finishing and foam application of coatings to its stitchbonded fabrics. The foam application of finishes to prevent pilling has been an important factor in expanding the companys range of products. Tietex also has developed 44-gauge stitchbonding equipment.Tietex now has the most diversified range of products in the stitchbonding business. Home furnishings products include mattress ticking, bedspread and drapery fabrics. The development of the stitchbonded mattress ticking by Tietex virtually eliminated the osnaburg cotton ticking from the market. Expansion And Diversification By TietexAfter the sudden death of Arno Wildeman, his son Martin took over the reins of the company and continued to expand and diversify the company in accordance with his fathers long-range plans. The company has expanded its Thailand-based plant, Tietex Asia Ltd., which was built in 1997. Some of the output of the Thailand plant is sold in Asia for use in footwear, hunting and recreational products. The company now is considering building a plant in Poland in order to better serve the European market.Recently, the company has developed a line of stitchbonded upholstery fabrics. An affiliated U.S. company, Interflex Laser Engravers, Spartanburg, produces flexographic printing rollers for Tietex, as well as rollers for flexographic printing of film and other materials for the packaging industry. New Techniques For Stitchbonding

Karl Mayer’ latest machine, the Multiknit, produces fabric with a double-sided knit effect.Karl Mayer of Germany has modified the basic Malimo technology to produce three-dimensional fabrics. Using these techniques, fabrics can be produced that have low specific weight, good compressive elasticity and moldability, and possible use as polyurethane foam replacement in automotive and other seating uses.The Kunit three-dimensional fabrics made of staple fibers are comprised of one stitch side and one pile loop side that has an almost vertical fiber arrangement. The lengthwise-oriented fibrous web is folded and compacted into a pile fiber web at high speed and supported by a brush bar. The fibers are pressed into needle hooks by the brush bar to form a stitch. In the Multiknit system, a fleece fabric with plain stitches on one side that has been made by the Kunit process is used as the Multiknit base fabric. The double-sided knit effect of the Multiknit fabric is produced by forming the fibrous content of the pile folds into loops to produce the second knit surface. The Outlook For StitchbondingThe growth in stitchbonded fabrics will be relatively modest in home furnishings and more conventional types of industrial fabrics. The greatest potential will be in fabrics for composites and fiber-reinforced polymers (FRP), and in products to replace polyurethane cushioning in automotive and furniture seating. The availability of stitchbonding equipment from a high-quality and development-oriented company like Karl Mayer should also be a key factor in the growth of these newer applications.June 2002

QuikWater Heaters Provide Clean Efficient Operation

QuikWater Heaters ProvideClean, Efficient OperationRecent tests reveal the Ultra-low NOx direct contact water heater from the QuikWater Division of Tulsa, Okla.-based Webco Industries Inc. produces NOx emissions of 9 parts per million or less without using external controls, while maintaining 99-percent thermal efficiency.The heaters consume energy only when hot water is being used. A patented dry firing chamber permits complete combustion, and fuel savings of up to 50 percent are possible, according to the company.July 2002

Debate Begins On Textile Tariff Cuts

T

he opening salvos have been fired in what will be a months-long battle over whether and

how much to cut textile and apparel tariffs during the current round of global trade negotiations

by World Trade Organization (WTO) members.

U.S. Trade Representative Robert Zoellick asked the U.S. International Trade Commission to

conduct hearings to assess the probable economic impact of tariff reductions on U.S. industries.

On the basis of information gained, he will make recommendations to President George W. Bush

this month with respect to the U.S. negotiating position.

At the commission’s recent hearing, Charles V. Bremer, vice president for international

trade at the American Textile Manufacturers Institute (ATMI), said the textile industry “cannot

countenance or withstand” any further tariff cuts.

He added, “It simply is unthinkable for the United States to grant further tariff

concessions to countries which have not even lived up to their Uruguay round of tariff and trade

bargains.”

On the other hand, Brenda Jacobs of the U.S. Association of Importers of Textiles and

Apparel said high tariffs do not protect U.S. industries from competition, and they add to the cost

of consumer products.

Jacobs said the United States should not “unilaterally disarm,” but the trade talks should

result in reciprocal reductions of tariffs and other trade barriers.

Administration Hangs Tough On Strong-Dollar Policy

Treasury Secretary Paul H. O’Neil has made it crystal clear that the Bush administration has

no intention of altering its policies supporting a strong dollar, a position that U.S. textile

manufacturers contend is having a devastating impact on business.

While admitting that some industries are hurt by the strong dollar, O’Neil told senators at

a recent Banking Committee hearing that he is much more concerned about the impact a weaker dollar

would have on consumer prices.

He told the senators, “I don’t know anyone who wants to reduce imports. If we take steps to

reduce imports, we become more of an isolated country and consumers pay more for their products.”

The strong dollar, which industry economists say is overvalued by about 30 percent, makes

imports cheaper and exports more expensive. This situation is contributing to a major increase in

the U.S. trade deficit.

A spokesman for a coalition of some 50 labor, agriculture and business trade associations

told the senators the overvalued dollar has resulted in the loss of 750,000 jobs in manufacturing

and farming, including 175,000 jobs in the textile industry alone.

They contend that the overvalued dollar amounts to a “30-percent tax” on U.S.-manufactured

goods, which cuts them out of markets at home and abroad.

Farm Bill Continues Cotton Competitiveness Program

The Farm Bill approved by Congress continues the textile industry’s coveted three-step

cotton competitiveness program through July 2006. The competitiveness program is designed to make

adjustments when the price for domestic raw cotton —which U.S. mills are required by law to use —

is higher than the world price.

Under the competitiveness program, the secretary of agriculture calculates the world price

for raw cotton. When the domestic price exceeds the world price, textile mills and cotton shippers

are paid the difference between the two prices. If the difference persists, mills are allowed to

import raw cotton.

Under the program, mills were required to pay the first 1.25 cents per pound of the subsidy,

but under the new legislation, that requirement is waived. U.S. manufacturers say the 1.25-cent

threshold puts them at a competitive disadvantage with overseas manufacturers and could cost as

much as $50 million annually.

June 2002