MONTGOMERY, Alabama — July 2, 2024 — Governor Kay Ivey praised Alabama’s robust manufacturing sector today in honor of ‘Made in the USA’ Day, highlighting its role in driving economic growth statewide through high-quality jobs and products in demand worldwide.

Governor Ivey emphasized Alabama’s status as a powerhouse in U.S. manufacturing, ranking in the top 5 states for manufacturing job concentration. The sector contributes approximately 17% of the state’s Gross Domestic Product, with an economic output exceeding $40 billion annually.

“Some of the best products found around the world are produced right here in Alabama,” said Governor Ivey. The ‘Made in Alabama’ badge has become a globally recognized symbol of unbeatable craftsmanship and unmatched quality.”

The Ivey Administration continues to prioritize initiatives that support and expand the manufacturing sector, including workforce development programs, investment in infrastructure and fostering a pro-business climate. These efforts have resulted in significant job creation and economic development across the state.

“Alabama’s manufacturers exemplify the best of American industry, and their contributions are vital contributors to our state’s economic resilience and national industries. ‘Made in the USA’ Day is celebrated every day here in Alabama because our state is a recognized leader when it comes to producing world-class products,” added Governor Ivey.

‘Made in the USA’ Day, celebrated on July 2, boosts sales of locally made products and honors the companies and individuals behind them.

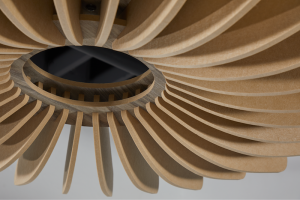

With over 275,000 people employed at more than 4,000 enterprises, Alabama’s manufacturing landscape is both diverse and dynamic. The state serves as a key automotive manufacturing hub, a leader in aerospace and a top U.S. producer of steel and advanced materials.

Alabama is home to many renowned manufacturing brands and successful homegrown companies, as well as smaller producers turning out first-class consumer items.

“Alabama’s manufacturing sector has witnessed remarkable growth across numerous industries, benefiting communities and families statewide,” said Ellen McNair, secretary of the Alabama Department of Commerce. “Manufacturers statewide are dedicated to excellence and innovative advancements that propel Alabama toward a more prosperous future.”

Moreover, manufactured goods represent a substantial portion of Alabama’s exports, totaling a record $27.4 billion in 2023, shipped to 190 countries. Last year, Alabama became the top auto-exporting state for the first time.

“Alabama is a hub for manufacturing. Thanks to Governor Ivey’s leadership and the hardworking men and women of this state, we continue breaking record after record,” said Manufacture Alabama President and CEO Jon Barganier. “Not only do our manufacturing industries positively impact Alabama through their $40 billion annual economic impact, but they provide great opportunities for our people. Through these good paying jobs, more Alabamians are able to live, work and raise a family here.”

According to the National Association of Manufacturers, average annual wages in Alabama’s manufacturing sector exceed $82,000 — significantly higher than the state average.

Posted: July 6, 2024

Source: The Office of Alabama Governor Kay Ivey