For many months now, the Rupp Report has informed its readers about the volatile development in the

global cotton markets and cotton prices. As everybody in the trade knows, these prices are causing

a lot of problems for many countries that have a strong dependence on cotton.

At several exhibitions and meetings over the past few months, subscribers and readers from

all over the world have expressed their wish to be informed frequently about the development of the

cotton markets and its prices, especially in these critical times. So here are the developments of

the past few weeks since the last Rupp Report about cotton in May 2011 (See ”

The

Rupp Report: Rollercoaster Cotton,” www.

TextileWorld.com, May 10, 2011). As usual, these cotton reflections are based

on various sources, mainly from the British traders Plexus Cotton Ltd., but also from organizations

such as the International Cotton Advisory Committee (ICAC) in Washington and the Bremen Cotton

Exchange in Germany.

Two Different Markets

On May 26, Plexus reported: “NY futures closed again mixed this week, but this time it was

July that dropped 462 points to close at 151.03 cents, while December rallied 838 points to close

at 127.57 cents.

“After the July/Dec inversion grew from less than 21 cents to over 38 cents a week ago, it

has once again started to come in, closing today at less than 24 cents.”

As Plexus noted: “It seems as if we were dealing with two different markets at the moment! On

the one hand there is current crop …, with delays, cancellations and high-priced inventories ….

On the other hand there is new crop, which is getting a lot of support due to the uncertainty in

some key growing areas after a less than ideal start.

Furthermore, Plexus reported, US export cancellations of 62,300 running bales more than

offset new sales of 29,300 bales for current crop and 21,800 bales for next marketing year,

providing an impression that the markets are calming down. In addition, there was a slowdown in the

shipments of 285,700 running bales. So the question became apparent: “How many of the outstanding

3.1 million bales in commitments will ultimately be exported by the end of July [from the United

States]?”

Up Again And Export Problems

Then, on June 2 came this report: “NY futures moved sharply higher this week, with July

rallying 1321 points to close at 164.24 cents, while December gained 1266 points to close at 139.23

cents.” And in West Texas the weather was still very dry. Plexus reported: “It is difficult to

estimate where exactly the US crop stands today, because there is still time to rectify some of the

problems, but unless we see an immediate improvement we are afraid that the US crop won’t yield

much more than 16.5 million bales.”

This projection of a smaller US crop would certainly cause some export problems, Plexus

noted. “The US has already committed around 5.8 million statistical bales for export next season,

which compares to just 1.4 million bales of forward sales of the previous year. Combined with the

3.8 million bales in domestic mill use, the total number of bales owed is therefore approaching the

ten million mark or roughly 60% of potential production. This means that shippers will be forced to

step on the breaks in regards to additional sales ….

“However, judging from past experience, other cotton-growing countries are not quite able to

jump on the bandwagon in a very short time. They simply don’t have the same logistics capabilities

as the United States, which is able to export some 400,000 to 500,000 bales weekly. Therefore,

Plexus warned, buyers who still have to fill third and fourth quarter commitments should not wait

too long to place orders.

Food Is The Major Competitor

Based on the June 2 numbers, Plexus noted that many cotton traders still believe prices will

fall back to a longer-term average. This could be, but food crops offer strong competition: Growers

get US$7 for a bushel of corn and US$14 for soybeans. It seems to be a tough job for cotton to

remain competitive. As Plexus noted: “As long as food prices remain high, cotton will have to be

attractively priced as well. A growing world population and rising protein consumption combined

with the fact that more food is being used to produce energy and to feed livestock should all but

guarantee that corn and soybean prices will remain at elevated levels for years to come.”

The Change

But over the next two weeks, there was a sharp drop in New York futures, with July falling a

total of 1,828 points by June 16 to close at 145.96 cents, and December falling a total of 1,905

points to close at 120.18 cents. There are a few reasons outside the cotton trade that are

influencing this development: for example, the uncertainty with the euro, including the Greek debt

crisis. Probably other countries will follow, as has been mentioned in all important financial

newspapers.

However, according to Plexus, “demand in the physical [cotton] market has basically been

non-existent lately. Mills are still trying to digest high-priced inventories of cotton, yarn and

fabrics and with the huge price swings we have seen in recent months, there is a lot of confusion

as to where a sustainable price level for cotton really is.

“The latest US export sales report was actually a pleasant surprise after 11 consecutive

weeks of negative numbers in current crop. Net sales of Upland and Pima cotton amounted to 10,300

running bales for this season and 39,200 running bales for next marketing year. Shipments of

227,100 running bales reduced the outstanding balance for the current marketing year to just 2.2

million running bales (last year 3.4 million bales) and … at the current pace of shipment all the

inventory would be gone by September.”

Rebound Of Global Stocks Reported

Also, on June 1, ICAC was reporting a rebound of global cotton stocks in 2011/12, noting that

“This season started with a firm demand from spinning mills, which were looking to rebuild their

stocks depleted in 2009/10, but is ending with weaker demand, mainly due to high cotton prices.”

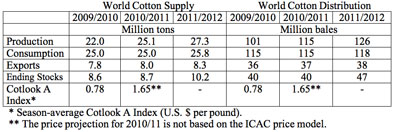

The following table showing world cotton supply and distribution, provided by ICAC, is

self-explanatory:

ICAC reported: “Global mill use is expected to resume increasing in 2011/12, driven by a

projected robust global economic growth and boosted by increased production, but moderated by

relatively high cotton prices and competition from chemical fibers. … The world ending

stocks-to-use ratio could rebound to 40% in 2011/12.

“The Secretariat believes that the season-average Cotlook A Index will decline significantly

in 2011/12, although it will probably remain above the ten-year average of $0.60 per pound.”

Tight Supplies

However, as Plexus noted on June 16, “remaining supplies in the US are very tight and may not

be enough to meet existing export commitments until October, plus the coming US crop is in trouble

and may yield several million bales less than what was expected just a month or two ago ….”

And what exactly is the annual demand: 119 million or 114 million bales? Again, the heat is

on.

June 21, 2011