The third edition of the biennial exhibition ITMA Asia + CITME will welcome the global textile

industry June 12-16, 2012, to the Shanghai New International Expo Centre (SNIEC) in Shanghai’s

Pudong district. Recognized as the largest international textile machinery showcase in Asia, the

show combines two previously independently produced events — the International Textile Machinery

Exhibition (ITMA) Asia and the China International Textile Machinery Exhibition (CITME) — in an

effort to more effectively promote textile machinery and technology in Asia and strengthen

cooperation between international textile and textile machinery industries.

The event’s owners — the European Committee of Textile Machinery Manufacturers (CEMATEX); the

Sub-Council of Textile Industry, China Council for the Promotion of International Trade

(CCPIT-TEX); China Textile Machinery Association (CTMA); and China International Exhibition Center

Group Corp. (CIEC) — have once again selected the Beijing Textile Machinery International

Exhibition Co. Ltd. (BJITME) and co-organizer MP International Pte Ltd to organize the event. The

Japan Textile Machinery Association (JTMA) also is a partner organization involved in the event.

ITMA Asia + CITME 2010 welcomed 82,000 visitors to see the products and services of 1,171

exhibitors.

“Having held two successful presentations of the ITMA Asia + CITME combined show in 2008 and

2010, we are confident that the upcoming exhibition will create enhanced and new marketing and

networking opportunities for both Chinese and international textile and textile machinery

manufacturers, especially those offering eco-friendly solutions,” said Stephen Combes, president,

CEMATEX. “The combined show has been highly recognised by leading textile and textile machinery

industry players as it offers them a cost-effective showcase for their products and services in

Asia. With the recovery of the world economy and the beginning of China’s 12th Five-Year Plan, we

are confident that the combined show will score another success.”

Exhibitors And Visitors

ITMA Asia + CITME 2010 saw 1,171 exhibitors from 28 countries and regions — the greatest

number of which came from China, Germany, Italy, Taiwan and Japan; and 82,000 visitors from 99

countries and regions. The greatest number of overseas visitors came from India, Japan, Taiwan,

Thailand and Korea. More than 20 percent of visitors were from overseas.

Show organizers expect more than 1,300 companies from approximately 30 economies will exhibit

at the 2012 edition, filling approximately 130,000 square meters of floor space in 11 halls at

SNIEC. As of Textile World’s press time, more than 100 prospective exhibitors are on the wait list.

Chinese companies have reserved nearly 50 percent of the available exhibit space. Companies

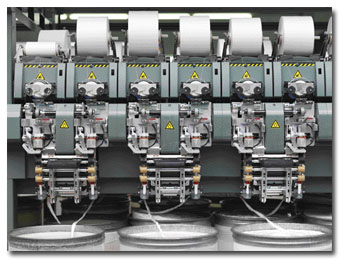

from Germany, Italy, Switzerland and Japan form the next-largest exhibitor group. Spinning will be

the most strongly represented sector at the show, followed by knitting, dyeing and finishing,

weaving, and winding.

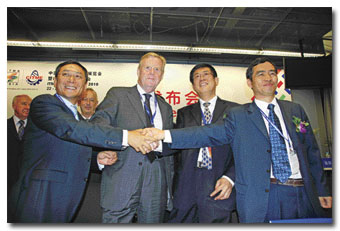

(left to right) ITMA Asia + CITME 2010 Supervisory Committee members Xu Yingxin, A.E.

Roberts, Wang Shutian and He Cailong

Show organizers expect nearly 100,000 visitors from all sectors of the global textile

industry to attend ITMA Asia + CITME 2012. To ensure high-quality visitors, guests will be required

to pay a small fee for an entry badge. Visitors may select a five-day pass for 100 renminbi or a

single-day pass for 50 renminbi. Both passes are available at a 40-percent discount if guests

register online prior to June 8. Visitors registering online also will be able to print a badge

prior to the show.

“The combined show is now well entrenched in the textile machinery exhibition calendar,” said

Maria Avery, secretary general, CEMATEX. “It draws leading textile machinery manufacturers and is a

must-attend showcase for the Asian market, offering plenty of business and networking

opportunities.”

Product Categories

Products will be arranged into 17 chapters as follows:

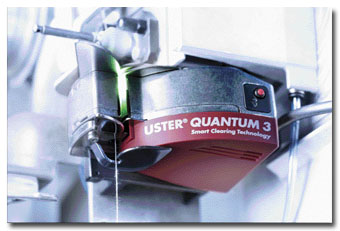

- Chapter 1 – Machinery for spinning preparation, man-made fiber production and spinning; and

auxiliary machinery and accessories; - Chapter 2 – Machinery for winding, texturing and twisting; and auxiliary machinery and

accessories; - Chapter 3 – Machinery for web formation, bonding and finishing of nonwovens and felting; and

auxiliary machinery and accessories; - Chapter 4 – Machinery for weaving preparation, weaving and tufting machinery; and auxiliary

machinery and accessories; - Chapter 5 – Knitting and hosiery machinery, auxiliary machinery and accessories;

- Chapter 6 – Embroidery machinery, auxiliary machinery and accessories;

- Chapter 7 – Braiding machinery and accessories;

- Chapter 8 – Machinery for washing, bleaching, dyeing, printing, drying, finishing, cutting,

rolling and folding; and auxiliary machinery and accessories; - Chapter 9 – Garment-making machinery, other textile processing machinery, auxiliary machinery

and accessories; - Chapter 10 – Laboratory testing and measuring equipment and accessories;

- Chapter 11 – Transport, handling, logistics, storing and packing equipment and

accessories; - Chapter 12 – Equipment for recycling, waste reduction, and pollution prevention; and

accessories; - Chapter 13 – Software for design, data monitoring, processing and integrated production;

- Chapter 14 – Dyestuffs and chemical products for the textile industry;

- Chapter 15 – Equipment and products to ensure machinery and plant operations;

- Chapter 16 – Services for the textile industry; and

- Chapter 17 – Research and educational institutions.

ITMA Asia + CITME 2012 organizers affirm that intellectual property (IPR) infringements will

not be tolerated, and stringent regulations will be enforced. An active IPR office again will be

available onsite to assist exhibitors who have suspected patent issues. Exhibitors may photograph

and film their own stands but are prohibited from photographing and filming other exhibitor’s

stands.

Blaise Godet, Switzerland’s ambassador to China (center), and Christian Kuoni, CEO, Jakob

Müller AG, and president, SWISSMEM Textile Machinery Division (right), at Jakob Müller’s booth at

ITMA Asia + CITME 2010

Growing Machinery Market

According to San Jose, Calif.-based market research firm Global Industry Analysts Inc., the

global textile machinery market is predicted to reach US$20.75 billion by 2015, with the Asia

Pacific region comprising the largest market.

The 2010 International Textile Machinery Shipment Statistics from The International Textile

Manufacturers Federation (ITMF), Switzerland, indicate that global machinery demand is on the

upswing, and that significant investments have been made in short-staple spindles, open-end rotors,

texturing spindles, shuttleless looms, circular knitting machines and electronic flat knitting

machines.

“Currently, the textile machinery industry report card is looking much better compared to the

previous two years,” said CEMATEX Board Member Fritz Mayer. “[ITMF’s statistics] show that

investments, which were reduced during the 2008 crisis, have picked up significantly. In fact, I’ve

been told that a number of machinery manufacturers have full order books, with delivery times, in

some cases, of up to two years.

“As the global economy continues to show strong signs of recovery, we expect our 2012 edition

to be even bigger than the previous showcase in 2010,” he added.

For more information about ITMA Asia + CITME 2012, visit

itmaasia.com.

March/April 2012