RESEARCH TRIANGLE PARK, N.C. — July 22, 2024 — Every year, students from all over the world participate in AATCC’s Concept 2 Consumer (C2C) Student Design competition. This competition is a poster competition that allows students the opportunity to showcase their creative design and problem-solving skills in textile/apparel design. The 2024 theme, “Vibrant Vacation — Colorful Resort Wear,” asked students to design a colorful resort wear apparel line that includes the use of sustainable fibers, dyes, or printing technology. Students had to research color trends and define the target market, keeping in mind color, quality, and sustainability. As part of AATCC’s mission to empower a more innovative, informed, and sustainable future, students were also asked to include two to three AATCC Test Methods that would help verify their product sustainability claims.

RESEARCH TRIANGLE PARK, N.C. — July 22, 2024 — Every year, students from all over the world participate in AATCC’s Concept 2 Consumer (C2C) Student Design competition. This competition is a poster competition that allows students the opportunity to showcase their creative design and problem-solving skills in textile/apparel design. The 2024 theme, “Vibrant Vacation — Colorful Resort Wear,” asked students to design a colorful resort wear apparel line that includes the use of sustainable fibers, dyes, or printing technology. Students had to research color trends and define the target market, keeping in mind color, quality, and sustainability. As part of AATCC’s mission to empower a more innovative, informed, and sustainable future, students were also asked to include two to three AATCC Test Methods that would help verify their product sustainability claims.

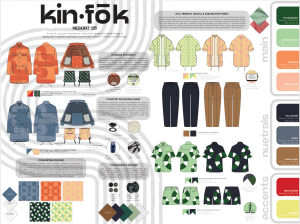

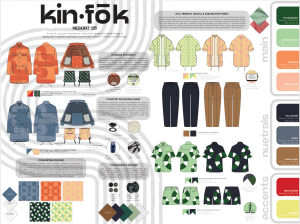

First Place

This year’s first-place winner is Jessica Singleton. She is pursuing a PhD in Textile Technology at North Carolina State University’s (NCSU) Wilson College of Textiles. Singleton’s winning entry, titled Kinfolk, is a resort capsule menswear collection driven by technology and designed to ignite inspiration and foster cultural interconnectedness. She focused on eco-friendly digital and sublimation printing for the collection, as well as comfort and convenience—tailoring the collection to fit diverse body shapes and sizes.

This year’s first-place winner is Jessica Singleton. She is pursuing a PhD in Textile Technology at North Carolina State University’s (NCSU) Wilson College of Textiles. Singleton’s winning entry, titled Kinfolk, is a resort capsule menswear collection driven by technology and designed to ignite inspiration and foster cultural interconnectedness. She focused on eco-friendly digital and sublimation printing for the collection, as well as comfort and convenience—tailoring the collection to fit diverse body shapes and sizes.

Singleton says that she “learned more about color standards and how to incorporate them into my own brand.” She used AATCC Test Methods TM111, Test Method for Weather Resistance of Textiles: Exposure to Daylight and Weather; TM106, AATCC TM106 Test Method for Colorfastness to Water: Sea; and TM125, Colorfastness to Perspiration and Light to validate her product line’s quality and sustainability.

Singleton says that she “learned more about color standards and how to incorporate them into my own brand.” She used AATCC Test Methods TM111, Test Method for Weather Resistance of Textiles: Exposure to Daylight and Weather; TM106, AATCC TM106 Test Method for Colorfastness to Water: Sea; and TM125, Colorfastness to Perspiration and Light to validate her product line’s quality and sustainability.

For winning first place, Singleton was awarded US$1,000 from AATCC, a US$500 Spoonflower Gift Certificate, a Datacolor ColorReader, and one year of free AATCC Student Membership.

Second Place

This year’s second-place winner is Lianna DeLuna, pursuing a degree in Apparel Design and Manufacturing at Texas Tech University. Her ski resort apparel line for young women, A Bright Chill, is inspired by the patterns and colors of the Arctic, from the shapes of ice crystals to the colors of the Aurora Borealis. The sustainability focus of this line focuses on the use of recycled polyester and faux fur.

This year’s second-place winner is Lianna DeLuna, pursuing a degree in Apparel Design and Manufacturing at Texas Tech University. Her ski resort apparel line for young women, A Bright Chill, is inspired by the patterns and colors of the Arctic, from the shapes of ice crystals to the colors of the Aurora Borealis. The sustainability focus of this line focuses on the use of recycled polyester and faux fur.

“This competition pushed me to expand my knowledge about sustainable practices and has inspired me to implement them in my future design projects,” says DeLuna. “In the future, I hope to start my own brand that challenges me to think sustainably with the textiles and patterns I use.”

The AATCC test methods she used included TM111, Weather Resistance of Textiles: Exposure to Daylight and Weather; TM16.1, Colorfastness to Light: Outdoor; and TM22, Water Repellency: Spray Test—validating the kinds of performance these products will have to embody as ski resort apparel.

The AATCC test methods she used included TM111, Weather Resistance of Textiles: Exposure to Daylight and Weather; TM16.1, Colorfastness to Light: Outdoor; and TM22, Water Repellency: Spray Test—validating the kinds of performance these products will have to embody as ski resort apparel.

For second place, DeLuna was awarded US$750 from AATCC, a US$250 Spoonflower Gift Certificate, a Datacolor ColorReader, and one year of free AATCC Student Membership.

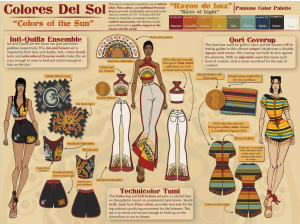

Third Place

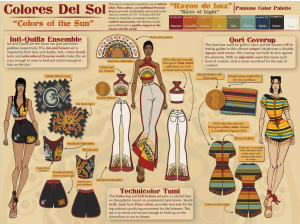

This year’s third-place winner is Samantha “Sammie” Neno. She is pursuing a degree in Apparel Design at Auburn University. Her young women’s resort wear collection, entitled Colores Del Sol, is centered around ethical labor, Pima cotton, and traditional natural Peruvian dyes.

This year’s third-place winner is Samantha “Sammie” Neno. She is pursuing a degree in Apparel Design at Auburn University. Her young women’s resort wear collection, entitled Colores Del Sol, is centered around ethical labor, Pima cotton, and traditional natural Peruvian dyes.

Neno says that the competition “was a wonderful experience that not only helped me learn digital design, but also gave me the opportunity to research topics from chemistry to ethical labor. This allowed me to grow confident in my skills as a designer, which will help me as I continue my time at Auburn and discern my career goals.”

She used AATCC TM16.1, Colorfastness to Light: Outdoor; TM106 Colorfastness to Water: Sea; and TM162 Colorfastness to Water: Chlorinated Pool to test the fastness of the natural dyes on her resort wear line.

She used AATCC TM16.1, Colorfastness to Light: Outdoor; TM106 Colorfastness to Water: Sea; and TM162 Colorfastness to Water: Chlorinated Pool to test the fastness of the natural dyes on her resort wear line.

Neno’s third-place prizes include US$200 from AATCC, a US$125 Spoonflower Gift Certificate, a Datacolor ColorReader, and one year of free AATCC Student Membership.

Developers, Judges, and Sponsors

AATCC would like to extend thanks and appreciation to the following developers, judges, and sponsors. Without their expertise and assistance, the competition would not have been possible.

Developers

- Sandra Johnson, Color Solutions International

- Kerry King, North Carolina State University

- Muditha Senanayake, California State Polytechnic University, Pomona

Judges

- Lisa Beck, Datacolor

- Craig Crawford, CrawfordIT and Differently Enabled

- Connie Huffa, Fabdesigns Inc.

- Julie Katzenberger, QA Management

- Lauren Koury, Carolina Hosiery

- Kristie Rhodes, Cotton Incorporated

- Anita Whitlow, Jeffries Socks

- Carrie Yates, Cotton Incorporated

Sponsors

Posted: July 22, 2024

Source: AATCC

![]() LOS ANGELES — July 22, 2024 — SHEIN, a global fashion and lifestyle online retailer, hosted its second annual Campus Retreat in Los Angeles on Friday, July 19 and Saturday, July 20. The event commenced with a Friday evening reception at the Mondrian Hotel in Los Angeles, welcoming more than 150 of the nation’s top SHEIN campus ambassadors.

LOS ANGELES — July 22, 2024 — SHEIN, a global fashion and lifestyle online retailer, hosted its second annual Campus Retreat in Los Angeles on Friday, July 19 and Saturday, July 20. The event commenced with a Friday evening reception at the Mondrian Hotel in Los Angeles, welcoming more than 150 of the nation’s top SHEIN campus ambassadors.