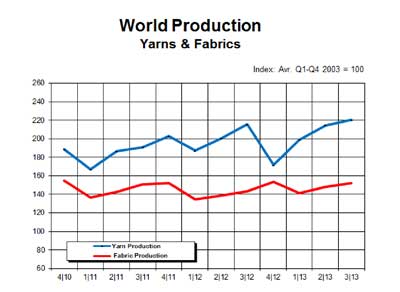

ZURICH — February 25, 2014 — Global yarn production increased in Q3/2013 in comparison to the previous one as a result of higher output in Asia, North and South America while production fell in Europe. Year-on-year global yarn production was up as well with all regions recording higher output levels. Worldwide yarn stocks were slightly lower due to lower inventories in South America, Asia and Europe. On an annual basis, global yarn stocks were up with all regions recording higher inventories. Yarn orders in Europe and Brazil rose in Q3/2013. Compared to last year’s quarter, yarn orders were higher in Europe, but lower in Brazil.

Global fabric output was up in Q3/2013 as a consequence of higher production in South America and Asia, and despite lower output in Europe. Year-on-year fabric production rose in Asia and Europe, but dropped in South America. Fabric stocks were slightly higher globally as a result of higher inventories in Europe and Asia, while stocks were reduced in South and North America. In comparison to last year’s quarter, worldwide stocks feel due to lower inventories in South and North America, with stock up in Europe and Asia. Fabric order in Europe rose in Q3/2013, but decreased in Asia. On an annual basis, fabric stocks were up in Brazil and Europe.

Estimates for yarn production for Q4/2013 are positive in Asia and Europe, and unchanged in North and South America. Estimates for fabric production for Q4/2013 are positive in Europe and North America and unchanged in Asia and South America. The outlook for yarn production for Q1/2014 is slightly positive in Asia and unchanged in Europe and South America. The outlook for fabric production for Q1/2014 is positive in Asia and South America, and unchanged in Europe.

In comparison to the previous quarter, world yarn output rose in Q3/2014 by 2.8 percent due to higher output in South America(+3 percent), Asia (+2.9 percent), as well as in North America (+2.3 percent) despite a reduction in Europe (-2.8 percent). In comparison to Q3/2012, global yarn production rose by 2.3 percent as a result of higher production levels in South America (+5 percent), North America (+4.7 percent), Europe (+3.1 percent) and Asia (+2.2 percent).

Compared with the previous quarter, global fabric production rose in Q3/2013 by 2.9 percent with South America and Asia recording the highest outputs of 4.3- and 3.7-percent respectively, while Europe’s production fell by 7.2 percent. Year-on-year global fabric production was up as well (6.6 percent) with Asia recording a production jump of 9.3 percent and Europe of 3.2 percent, while South America recorded a slump of 19.5 percent.

Global yarn inventories were slightly down (0.6 percent) in Q3/2013 due to lower stocks in South America (-3.3 percent), Europe (-0.3 percent) and Asia (-0.2 percent). On an annual basis, global yarn inventories rose by 9.4 percent with all regions reporting higher stocks (Asia 10.3 percent; Europe 0.6 percent; and South America 0.4 percent).

Global fabric stocks in Q3/2013 increased slightly by 0.3 percent resulting from higher inventories in Europe (+1.3 percent) and Asia (0.5 percent), and despite lower stocks in South America (-0.6 percent) and North America (-0.2 percent). Global fabric stocks were down year-on-year by 4.8 percent resulting from lower stocks in South America and North America (-22.3 percent and -2.1 percent respectively). Fabric stocks in Europe and Asia on the other hand rose by 1.5 percent and 1.1 percent respectively.

Yarn orders in Europe and Brazil were up in Q3/2013 by 36.9 percent and 2 percent respectively. Compared to last year’s quarter, yarn orders surged in Europe by 35.6 percent, but dropped in Brazil by 11.1 percent.

In Q3/2013, fabric orders rose in Europe by 1.2 percent, but were down in Brazil by 0.1 percent. On an annual basis they were up in Brazil by 8.8 percent and in Europe by 4.1 percent.

Posted February 25, 2014

Source: ITMF