BRISTOL, Va. — October 7, 2024 — Universal Fibers is excited to announce the launch of Forbo Flooring Systems’ New Tessera Topology, the first collection in their Evolve+ series, using Thrive® matter yarn from Universal Fibers®.

BRISTOL, Va. — October 7, 2024 — Universal Fibers is excited to announce the launch of Forbo Flooring Systems’ New Tessera Topology, the first collection in their Evolve+ series, using Thrive® matter yarn from Universal Fibers®.

Thrive matter is the lowest carbon footprint yarn in the industry, made from 100-percent solution-dyed nylon 6 with 90-percent recycled content. This innovative yarn, paired with Forbo’s lean production processes, results in carpet tiles with more than 75-percent recycled content and a very low embodied carbon (less than 1.5kg CO2 per square meter). The collection is manufactured in facilities using 100-percent renewable energy, including both electricity and biogas, reinforcing Forbo’s commitment to reducing environmental impact.

Thrive matter is the lowest carbon footprint yarn in the industry, made from 100-percent solution-dyed nylon 6 with 90-percent recycled content. This innovative yarn, paired with Forbo’s lean production processes, results in carpet tiles with more than 75-percent recycled content and a very low embodied carbon (less than 1.5kg CO2 per square meter). The collection is manufactured in facilities using 100-percent renewable energy, including both electricity and biogas, reinforcing Forbo’s commitment to reducing environmental impact.

Donna Hannaway, head of Marketing UK and Ireland at Forbo Flooring Systems, said: “As a manufacturer, sustainability is extremely important to us at Forbo. Our core values are Renewability, Transparency and Circularity, and as such we’re always looking for ways to adapt and evolve our product portfolios in line with this, as well as to meet modern sustainability requirements. This means we are constantly developing new ways for architects and specifiers to incorporate environmentally friendly finishes into their projects, as with this new collection.”

Donna Hannaway, head of Marketing UK and Ireland at Forbo Flooring Systems, said: “As a manufacturer, sustainability is extremely important to us at Forbo. Our core values are Renewability, Transparency and Circularity, and as such we’re always looking for ways to adapt and evolve our product portfolios in line with this, as well as to meet modern sustainability requirements. This means we are constantly developing new ways for architects and specifiers to incorporate environmentally friendly finishes into their projects, as with this new collection.”

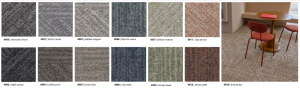

In addition to its environmental benefits, Tessera Topology offers a sophisticated, contemporary aesthetic. The collection features a geometric pattern that balances linear angles with organic textures, creating a unique and versatile design that brings warmth and character to any interior space. Designed and manufactured in the United Kingdom, Tessera Topology is available ex stock, making it ideal for office refurbishments and other fast-track projects. The collection also meets stringent indoor air quality standards, such as Indoor Air Comfort Gold and GUT certification, ensuring a healthier environment for end users.

Available in collection of beautiful neutral tones and muted accent, such as the subtle beige of Pebble Tangent and the earthy green of Willow Inverse, Tessera Topology provides an ideal solution for a wide range of projects. The tiles come in a standard 50x50cm format, so can be easily integrated with other products from Forbo’s existing Tessera range, offering endless design possibilities.

Available in collection of beautiful neutral tones and muted accent, such as the subtle beige of Pebble Tangent and the earthy green of Willow Inverse, Tessera Topology provides an ideal solution for a wide range of projects. The tiles come in a standard 50x50cm format, so can be easily integrated with other products from Forbo’s existing Tessera range, offering endless design possibilities.

Forbo’s Tessera carpet tiles can be installed adhesive free using IOBAC MagTabs™, allowing them to be easily removed and reused or recycled, supporting a circular economy. Forbo is also proud to have recently entered into partnership with the Salvation Army Trading Company, supporting it’s Take Back scheme and furniture shops with donations of reusable carpet tiles.

Universal Fibers are delighted that Tessera Topology marks a significant step forward in Forbo’s sustainability journey and is the first in the company’s Evolve+ series, a product line dedicated to enhanced sustainability and innovation in carpet tile manufacturing.

Universal Fibers are delighted that Tessera Topology marks a significant step forward in Forbo’s sustainability journey and is the first in the company’s Evolve+ series, a product line dedicated to enhanced sustainability and innovation in carpet tile manufacturing.

Phil Harmon, president of Universal Fibers, shared his thoughts on the collaboration: “Our work with Forbo has enabled the creation of an industry-leading product that aligns perfectly with the evolving demands of sustainability in the carpet tile industry. We are thrilled to see Thrive matter, our most sustainable fiber yet, contribute to Forbo’s sustainable vision.”

Posted: October 7, 2024

Source: Universal Fibers Inc. — A Bussiness Unit of Universal Fiber Systems LLC