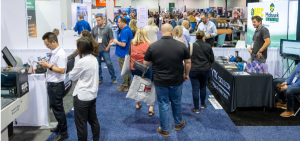

ANAHEIM, Calif. — October 17, 2024 — Advanced Textiles Expo® 2024, the largest event of Advanced Textiles Association® (ATA), concluded with resounding success September 24–26 at the Anaheim Convention Center. Once again held in conjunction with Sun Shading Expo North America — organized by Messe Stuttgart, founders of R + T and the world’s largest trade fair for roller shutters, doors/gates and sun shading systems–the combined events brought 4,295 attendees from across the globe.

ANAHEIM, Calif. — October 17, 2024 — Advanced Textiles Expo® 2024, the largest event of Advanced Textiles Association® (ATA), concluded with resounding success September 24–26 at the Anaheim Convention Center. Once again held in conjunction with Sun Shading Expo North America — organized by Messe Stuttgart, founders of R + T and the world’s largest trade fair for roller shutters, doors/gates and sun shading systems–the combined events brought 4,295 attendees from across the globe.

This year’s event served as a dynamic platform for innovation, collaboration and business opportunities in the textiles industry, with a bustling show floor of roughly 380 exhibitors between both expos. Exhibitors showcased the latest technological advancements and products, including space for exhibitors to hold meetings with colleagues and customers.

This year’s event served as a dynamic platform for innovation, collaboration and business opportunities in the textiles industry, with a bustling show floor of roughly 380 exhibitors between both expos. Exhibitors showcased the latest technological advancements and products, including space for exhibitors to hold meetings with colleagues and customers.

Steve Schiffman, president and CEO of ATA, expressed his excitement about the continued growth and impact of the expo. “Advanced Textiles Expo continues to evolve and this year set in motion a variety of changes designed to create greater engagement and continuous improvement while keeping people on the show floor,” he said. “Our community values networking opportunities that introduce them to new people and new ideas, and we’re delighted that expo is the platform where that happens. Whether that was at the Textiles Challenge, Industry Night or the Women’s Networking Walk, Advanced Textiles Expo keeps bringing the textiles industry together every year.”

The expo also included more than 25 educational “campfire” sessions, with education spanning 15 markets. Educational sessions included textiles in the new space age, how to be more environmentally conscious in fields such as medical textiles and fabrics, updates on the Awnings Safety Act and other federal law changes, and general topics such as climate change, succession planning and supply chain updates.

The final day featured a Marine Fabricators Association Roadshow, which presented a new topic every hour: From how to build a U-Zip with a built-in rain flap, to selecting the best project materials and general tips and tools in marine fabrication.

Exhibitor demonstrations included everything from welding technology to no-weld canopy system demonstrations, new generation cutting, piece cutting machines and more.

Attendees and exhibitors alike competed in the highly anticipated Textiles Challenge, a fun gameshow-like activity that put contestants to the test both in their knowledge and skill regarding all things textiles. Dan King of Davey Textile Solutions took home first place, while Felix Arwen from NASA Johnson Space Center came in second place, and Justin Wagner from Applied Research Associates Inc. (ARA) placed third.

A series of networking events brought together fabricators, manufacturers, suppliers and thought leaders. Attendees and exhibitors alike met to unwind after the closure of the show floor on day one at the opening reception. Later that night, the fun continued at Industry Night, hosted at the iconic House of Blues. Attendees enjoyed live music and a delicious catered barbecue dinner, making it a night of celebration and networking in a lively atmosphere.

Attendees took advantage of other educational sessions and networking opportunities, like a morning fun run/walk Sept. 25, Speed Networking, NextGen Networking and a live recording of the podcast, Talking Textiles.

Advanced Textiles Expo devoted its last day to women in the textiles industry, beginning the morning with a Women’s Networking Walk, and continuing with women’s leadership sessions that were both educational and empowering. Connie Huffa, CEO of Fabdesigns Inc., and Michelle Lea, chief marketing and sustainability officer at NILIT Ltd., shared both their experiences and the latest from their industries, and answered audience questions about being a woman in the textiles industry. A development session about setting boundaries and prioritizing a work-life balance followed the forum.

Camari Henderson-Zenon, a fabricator and owner of Camari’s Custom Canvas, agreed on the importance of coming together with others in textiles at her first expo.

“As a woman in textiles, attending Advanced Textiles Expo provides me the opportunity to stay current on all aspects of the textile market by networking with other men and women in the trade,” she said. “Along with a platform to share hands-on experiences, both good and bad, with vendor reps to positively shape the trajectory of the industry.”

Emerging Technologies Conference also returned this year September 23–24, following its successful debut last year. Exhibitors learned about topics such as technology transfer in textiles, smart clothing innovations and the use of AI in advanced fabrics. They also participated in the highly anticipated LEGO® networking session and a biomaterials workshop that explored sustainable textile innovations. The conference included its own opening reception, another opportunity for attendees to network.

David Fezer, an exhibitor from Alpha Tubular Motors, said being in his company’s “hometown” made Advanced Textiles Expo extra special this year.

“We had an incredible experience at Advanced Textiles Expo in Anaheim this September. We’re already looking forward to the next year in Indianapolis and can’t wait to see everyone again,” Fezer said. “Thank you to everyone who made this event such a success!”

As the premier event for the textiles industry, Advanced Textiles Expo 2024 continues to prove itself as the top-tier opportunity for professionals to discover new trends, forge partnerships and explore the future of textile technologies.

The next Advanced Textiles Expo will be held November 5–7, 2025, in Indianapolis. For more information, please visit AdvancedTextilesExpo.com.

Posted: October 17, 2024

Source: Advanced Textiles Association® (ATA)

![]() OBERTSHAUSEN, Germany — October 17, 2024 — With its exhibition at ITMA ASIA + CITME, KARL MAYER warp preparation focuses on sustainability and efficiency and hits the bull’s eye. The exhibits are among the top talking points at the KARL MAYER GROUP stand. On display here will be a latest-generation beam warping machine with a unique working speed of max. 1,200 m/min, the brand new CASCADE system for significantly reducing steam consumption, costs and environmental impact during sizing, and the equally new Smart Size Box – a sophisticated technology that makes a valuable contribution to the topic of predictive maintenance by monitoring the condition of wear components and thus aroused the curiosity of many visitors, including a delegation from Pinhua Garments Co.

OBERTSHAUSEN, Germany — October 17, 2024 — With its exhibition at ITMA ASIA + CITME, KARL MAYER warp preparation focuses on sustainability and efficiency and hits the bull’s eye. The exhibits are among the top talking points at the KARL MAYER GROUP stand. On display here will be a latest-generation beam warping machine with a unique working speed of max. 1,200 m/min, the brand new CASCADE system for significantly reducing steam consumption, costs and environmental impact during sizing, and the equally new Smart Size Box – a sophisticated technology that makes a valuable contribution to the topic of predictive maintenance by monitoring the condition of wear components and thus aroused the curiosity of many visitors, including a delegation from Pinhua Garments Co.