TEMPE, Ariz. — January 3, 2025 — Economic activity in the manufacturing sector contracted in December for the ninth consecutive month and the 25th time in the last 26 months, say the nation’s supply executives in the latest Manufacturing ISM® Report On Business®.

TEMPE, Ariz. — January 3, 2025 — Economic activity in the manufacturing sector contracted in December for the ninth consecutive month and the 25th time in the last 26 months, say the nation’s supply executives in the latest Manufacturing ISM® Report On Business®.

The report was issued today by Timothy R. Fiore, CPSM, C.P.M., Chair of the Institute for Supply Management® (ISM) Manufacturing Business Survey Committee:

“The Manufacturing PMI® registered 49.3 percent in December, 0.9 percentage point higher compared to the 48.4 percent recorded in November. The overall economy continued in expansion for the 56th month after one month of contraction in April 2020. (A Manufacturing PMI above 42.5 percent, over a period of time, generally indicates an expansion of the overall economy.) The New Orders Index continued in expansion territory for the second month after seven months of contraction, strengthening to 52.5 percent, 2.1 percentage points higher than the 50.4 percent recorded in November. The December reading of the Production Index (50.3 percent) is 3.5 percentage points higher than November’s figure of 46.8 percent. The index returned to expansion after six months in contraction. The Prices Index continued in expansion (or ‘increasing’) territory, registering 52.5 percent, up 2.2 percentage points compared to the reading of 50.3 percent in November. The Backlog of Orders Index registered 45.9 percent, up 4.1 percentage points compared to the 41.8 percent recorded in November. The Employment Index registered 45.3 percent, down 2.8 percentage points from November’s figure of 48.1 percent.

“The Supplier Deliveries Index indicated marginally slower deliveries, registering 50.1 percent, 1.4 percentage points higher than the 48.7 percent recorded in November. (Supplier Deliveries is the only ISM® Report On Business® index that is inversed; a reading of above 50 percent indicates slower deliveries, which is typical as the economy improves and customer demand increases.) The Inventories Index registered 48.4 percent, up 0.3 percentage point compared to November’s reading of 48.1 percent.

“The New Export Orders Index’s ‘unchanged’ reading of 50 percent is 1.3 percentage points higher than the 48.7 percent registered in November. The Imports Index remained in contraction territory in December, registering 49.7 percent, 2.1 percentage points higher than November’s reading of 47.6 percent.”

Fiore continues, “U.S. manufacturing activity contracted again in December, but at a slower rate compared to November. Demand showed signs of improving, while output stabilized and inputs stayed accommodative. Demand analysis includes: the (1) New Orders Index remaining in expansion territory, (2) New Export Orders Index increasing (up 1.3 percentage points and now ‘unchanged’), (3) Backlog of Orders Index slowing its rate of decline but continuing in contraction territory, and (4) Customers’ Inventories Index dropping into ‘too low’ territory. Output (measured by the Production and Employment indexes) was positive; factory output stabilized compared to November, indicating that panelists’ companies are executing to plan. Employment contracted as final head-count adjustments were likely taken to prepare for 2025. Inputs — defined as supplier deliveries, inventories, prices and imports — generally continued to accommodate future demand growth, with inventories and imports improving marginally (though remaining in contraction), prices increasing and supplier deliveries marginally slowing.

“Demand improved, production execution met November’s performance (and companies’ plans), de-staffing continued (but should end soon), and price growth was marginal. Fifty-two percent of manufacturing gross domestic product (GDP) contracted in December, down from 66 percent in November. The share of manufacturing sector GDP registering a composite PMI® calculation at or below 45 percent (a good barometer of overall manufacturing weakness) was 49 percent in December, a 1-percentage point increase compared to the 48 percent reported in November. None of the six largest manufacturing industries expanded in December, down from two in November,” said Fiore.

The seven manufacturing industries reporting growth in December — listed in order — are: Primary Metals; Electrical Equipment, Appliances & Components; Wood Products; Furniture & Related Products; Paper Products; Miscellaneous Manufacturing; and Plastics & Rubber Products. The seven industries reporting contraction in December — in the following order — are: Textile Mills; Fabricated Metal Products; Printing & Related Support Activities; Machinery; Chemical Products; Transportation Equipment; and Nonmetallic Mineral Products.

What Respondents Are Saying

“Slightly lower due to seasonality and end-of-year destocking.” [Chemical Products]

“Automotive and powersport volume decreases.” [Transportation Equipment]

“We are seeing a softening in sales. This is concerning as it’s our peak season.” [Food, Beverage & Tobacco Products]

“We are constrained by technical labor, despite higher-than-normal backlog.” [Computer & Electronic Products]

“Significant slowdown in production requirements in the last two months of the year.” [Machinery]

“Order levels well below forecast projections.” [Fabricated Metal Products]

“The increase in new orders has our plant at full capacity.” [Electrical Equipment, Appliances & Components]

“Combo of seasonal factors plus increased demand outlook for 2025.” [Miscellaneous Manufacturing]

“There is definitely an uptick this month, though not a stable one.” [Primary Metals]

“The orders have increased slightly due to seasonal restocking.” [Plastics & Rubber Products]

MANUFACTURING AT A GLANCE

December 2024 |

| Index |

Series

IndexDec |

Series

IndexNov |

Percentage

Point

Change |

Direction |

Rate of

Change |

Trend*

(Months) |

| Manufacturing PMI® |

49.3 |

48.4 |

+0.9 |

Contracting |

Slower |

9 |

| New Orders |

52.5 |

50.4 |

+2.1 |

Growing |

Faster |

2 |

| Production |

50.3 |

46.8 |

+3.5 |

Growing |

From

Contracting |

1 |

| Employment |

45.3 |

48.1 |

-2.8 |

Contracting |

Faster |

7 |

| Supplier Deliveries |

50.1 |

48.7 |

+1.4 |

Slowing |

From Faster |

1 |

| Inventories |

48.4 |

48.1 |

+0.3 |

Contracting |

Slower |

4 |

| Customers’ Inventories |

46.7 |

48.4 |

-1.7 |

Too Low |

Faster |

3 |

| Prices |

52.5 |

50.3 |

+2.2 |

Increasing |

Faster |

3 |

| Backlog of Orders |

45.9 |

41.8 |

+4.1 |

Contracting |

Slower |

27 |

| New Export Orders |

50.0 |

48.7 |

+1.3 |

Unchanged |

From

Contracting |

1 |

| Imports |

49.7 |

47.6 |

+2.1 |

Contracting |

Slower |

7 |

| OVERALL ECONOMY |

Growing |

Faster |

56 |

| Manufacturing Sector |

Contracting |

Slower |

9 |

Manufacturing ISM Report On Business data is seasonally adjusted for the New Orders, Production, Employment and Inventories indexes.

*Number of months moving in current direction.

Commoditites Reported Up/Down In Price And In Short Supply

Commodities Up in Price

Aluminum (13); Caustic Soda (2); Copper (3); Electronic Components; Labor — Temporary; Methanol; Natural Gas (3); Packaging Materials; Steel — General*; Steel — High Carbon; and Steel-Making Elements*.

Commodities Down in Price

Diesel Fuel (2); Plastic Resin (2); Polypropylene Resin; Solvents (2); Steel — General*; Steel — Hot Rolled (2); Steel — Scrap; and Steel-Making Elements*.

Commodities in Short Supply

Electrical Components (51); Electronic Components (9); and Labor — Construction Services and Skilled.

Note: The number of consecutive months the commodity is listed is indicated after each item.

*Indicates both up and down in price.

December 2024 Manufacturing Index Summaries

Manufacturing PMI®

The U.S. manufacturing sector contracted for the ninth consecutive month in December, as the Manufacturing PMI registered 49.3 percent, 0.9 percentage point higher compared to the 48.4 percent reported in November. “After breaking a 16-month streak of contraction by expanding in March, the manufacturing sector has contracted for the last nine months. Of the five subindexes that directly factor into the Manufacturing PMI, three (New Orders, Production and Supplier Deliveries) were in expansion territory, compared to only one in November. The Employment Index remained in contraction, but the New Orders Index moved further into expansion in December. Of the six biggest manufacturing industries, none registered growth,” says Fiore. A reading above 50 percent indicates that the manufacturing sector is generally expanding; below 50 percent indicates that it is generally contracting.

A Manufacturing PMI above 42.5 percent, over a period of time, generally indicates an expansion of the overall economy. Therefore, the December Manufacturing PMI® indicates the overall economy grew for the 56th straight month after last contracting in April 2020. “The past relationship between the Manufacturing PMI® and the overall economy indicates that the December reading (49.3 percent) corresponds to a change of plus-1.9 percent in real gross domestic product (GDP) on an annualized basis,” says Fiore.

The Last 12 Months

| Month |

Manufacturing

PMI® |

Month |

Manufacturing

PMI® |

| Dec 2024 |

49.3 |

Jun 2024 |

48.5 |

| Nov 2024 |

48.4 |

May 2024 |

48.7 |

| Oct 2024 |

46.5 |

Apr 2024 |

49.2 |

| Sep 2024 |

47.2 |

Mar 2024 |

50.3 |

| Aug 2024 |

47.2 |

Feb 2024 |

47.8 |

| Jul 2024 |

46.8 |

Jan 2024 |

49.1 |

| Average for 12 months – 48.3

High – 50.3

Low – 46.5 |

New Orders

ISM’s New Orders Index expanded in December for the second consecutive month after seven months in contraction, registering 52.5 percent, an increase of 2.1 percentage points compared to November’s figure of 50.4 percent. The New Orders Index hasn’t indicated consistent growth since a 24-month streak of expansion ended in May 2022. “Of the six largest manufacturing sectors, two (Food, Beverage & Tobacco Products; and Computer & Electronic Products) reported increased new orders. Panelists noted an improved level of demand performance, with a 1.5-to-1 ratio of positive comments versus those expressing concern about near-term demand, an improvement compared to November,” says Fiore. A New Orders Index above 52.3 percent, over time, is generally consistent with an increase in the Census Bureau’s series on manufacturing orders (in constant 2000 dollars).

The six manufacturing industries that reported growth in new orders in December, in order, are: Electrical Equipment, Appliances & Components; Paper Products; Food, Beverage & Tobacco Products; Miscellaneous Manufacturing; Primary Metals; and Computer & Electronic Products. The eight industries reporting a decline in new orders in December — in the following order — are: Textile Mills; Printing & Related Support Activities; Nonmetallic Mineral Products; Wood Products; Transportation Equipment; Fabricated Metal Products; Plastics & Rubber Products; and Machinery.

| New Orders |

%Higher |

%Same |

%Lower |

Net |

Index |

| Dec 2024 |

21.0 |

54.9 |

24.1 |

-3.1 |

52.5 |

| Nov 2024 |

21.0 |

54.3 |

24.7 |

-3.7 |

50.4 |

| Oct 2024 |

20.4 |

50.6 |

29.0 |

-8.6 |

47.1 |

| Sep 2024 |

17.6 |

56.1 |

26.3 |

-8.7 |

46.1 |

Production

The Production Index emerged into expansion territory in December, registering 50.3 percent, 3.5 percentage points higher than the November reading of 46.8 percent. Prior to this month’s reading, the index was in contraction territory for six consecutive months. The last time the index registered above 50 percent was in May (50.2 percent). Of the six largest manufacturing sectors, only one (Computer & Electronic Products) reported increased production. “Production levels were stable to November’s performance, indicating that re-planning factory floor activity has likely been completed, head counts are likely synchronized with factory demand, and panelists are fully staffed and aligned for 2025,” says Fiore. An index above 52.2 percent, over time, is generally consistent with an increase in the Federal Reserve Board’s Industrial Production figures.

The five industries reporting growth in production during the month of December are: Textile Mills; Plastics & Rubber Products; Wood Products; Computer & Electronic Products; and Primary Metals. The six industries reporting a decrease in production in December, in order, are: Printing & Related Support Activities; Fabricated Metal Products; Nonmetallic Mineral Products; Machinery; Chemical Products; and Transportation Equipment. Six industries reported no change in production levels in December as compared to November.

| Production |

%Higher |

%Same |

%Lower |

Net |

Index |

| Dec 2024 |

15.3 |

59.3 |

25.4 |

-10.1 |

50.3 |

| Nov 2024 |

15.9 |

63.2 |

20.9 |

-5.0 |

46.8 |

| Oct 2024 |

16.8 |

59.3 |

23.9 |

-7.1 |

46.2 |

| Sep 2024 |

17.6 |

60.7 |

21.7 |

-4.1 |

49.8 |

Employment

ISM’s Employment Index registered 45.3 percent in December, 2.8 percentage points lower than the November reading of 48.1 percent. “The index contracted for the seventh consecutive month and the 14th out of the last 15 months. Of the six big manufacturing sectors, none expanded employment in December. Respondents’ companies are continuing to reduce head counts through layoffs, attrition and hiring freezes. This action is supported in December by the approximately 1-to-2 ratio of hiring versus staff-reduction comments, compared to a 1-to-1.5 ratio the previous month, meaning more workforce reduction activity is occurring as we close 2025,” says Fiore. An Employment Index above 50.3 percent, over time, is generally consistent with an increase in the Bureau of Labor Statistics (BLS) data on manufacturing employment.

Of 18 manufacturing industries, the two industries reporting employment growth in December are: Electrical Equipment, Appliances & Components; and Plastics & Rubber Products. The nine industries reporting a decrease in employment in December, in the following order, are: Textile Mills; Fabricated Metal Products; Machinery; Chemical Products; Furniture & Related Products; Food, Beverage & Tobacco Products; Primary Metals; Transportation Equipment; and Miscellaneous Manufacturing. Six industries reported no change in employment levels in December as compared to November.

| Employment |

%Higher |

%Same |

%Lower |

Net |

Index |

| Dec 2024 |

7.0 |

75.3 |

17.7 |

-10.7 |

45.3 |

| Nov 2024 |

14.2 |

65.3 |

20.5 |

-6.3 |

48.1 |

| Oct 2024 |

9.0 |

70.6 |

20.4 |

-11.4 |

44.4 |

| Sep 2024 |

8.0 |

69.3 |

22.7 |

-14.7 |

43.9 |

Supplier Deliveries†

Delivery performance of suppliers to manufacturing organizations was marginally slower in December, with the Supplier Deliveries Index registering 50.1 percent, a 1.4-percentage point increase compared to the reading of 48.7 percent reported in November. This expansion follows a contraction in November preceded by four consecutive months of slower deliveries, with four straight months of faster deliveries before that. After a reading of 52.4 percent in September 2022, the index went into contraction territory the following month and remained there for 20 out of 21 months (with February 2024 as the exception). Of the six big industries, two (Computer & Electronic Products; and Food, Beverage & Tobacco Products) reported slower supplier deliveries in December. “Supplier deliveries moved into ‘slower’ territory as supplier delivery performance continues to meet the expectations of panelists’ customers,” says Fiore. A reading below 50 percent indicates faster deliveries, while a reading above 50 percent indicates slower deliveries.

The six manufacturing industries reporting slower supplier deliveries in December — listed in order — are: Furniture & Related Products; Nonmetallic Mineral Products; Primary Metals; Computer & Electronic Products; Electrical Equipment, Appliances & Components; and Food, Beverage & Tobacco Products. The three industries reporting faster supplier deliveries in December are: Fabricated Metal Products; Chemical Products; and Machinery. Eight industries reported no change in supplier deliveries in December as compared to November.

| Supplier Deliveries |

%Slower |

%Same |

%Faster |

Net |

Index |

| Dec 2024 |

6.4 |

87.4 |

6.2 |

+0.2 |

50.1 |

| Nov 2024 |

5.7 |

86.0 |

8.3 |

-2.6 |

48.7 |

| Oct 2024 |

11.9 |

80.1 |

8.0 |

+3.9 |

52.0 |

| Sep 2024 |

10.4 |

83.6 |

6.0 |

+4.4 |

52.2 |

Inventories

The Inventories Index registered 48.4 percent in December, up 0.3 percentage point compared to the reading of 48.1 percent reported in November. The last time the Inventories Index registered above 50 percent was in August, when it registered 50.3 percent. “Manufacturing inventories continue to contract, though rates have slowed in in the last two months as panelists continue to manage working capital. This month’s index reading indicating a slowing rate of contraction suggests that companies are willing to invest more for the future, to (1) better perform to their customers’ delivery demands or (2) advance material deliveries to avoid potential tariffs, or a combination of both. Of the six big industries, none reported expanding manufacturing inventories in December,” says Fiore. An Inventories Index greater than 44.4 percent, over time, is generally consistent with expansion in the Bureau of Economic Analysis (BEA) figures on overall manufacturing inventories (in chained 2000 dollars).

Of 18 manufacturing industries, the five industries reporting higher inventories in December are: Primary Metals; Wood Products; Furniture & Related Products; Nonmetallic Mineral Products; and Electrical Equipment, Appliances & Components. The eight industries reporting lower inventories in December — in the following order — are: Textile Mills; Fabricated Metal Products; Computer & Electronic Products; Chemical Products; Plastics & Rubber Products; Food, Beverage & Tobacco Products; Machinery; and Transportation Equipment.

| Inventories |

%Higher |

%Same |

%Lower |

Net |

Index |

| Dec 2024 |

14.4 |

64.8 |

20.8 |

-6.4 |

48.4 |

| Nov 2024 |

15.5 |

63.2 |

21.3 |

-5.8 |

48.1 |

| Oct 2024 |

14.2 |

59.1 |

26.7 |

-12.5 |

42.6 |

| Sep 2024 |

11.2 |

66.5 |

22.3 |

-11.1 |

43.9 |

Customers’ Inventories†

ISM’s Customers’ Inventories Index registered a reading of 46.7 percent in December, down 1.7 percentage points compared to the 48.4 percent reported in November. “Customers’ inventory levels in December have dropped to the high side of ‘too low.’ Panelists are reporting that the amounts of their products in their customers’ inventories suggest a demand level that is positive for future production,” says Fiore.

The four industries reporting customers’ inventories as too high in December are: Textile Mills; Wood Products; Plastics & Rubber Products; and Miscellaneous Manufacturing. The 10 industries reporting customers’ inventories as too low in December, in order, are: Food, Beverage & Tobacco Products; Paper Products; Furniture & Related Products; Electrical Equipment, Appliances & Components; Machinery; Primary Metals; Computer & Electronic Products; Fabricated Metal Products; Transportation Equipment; and Chemical Products.

Customers’

Inventories |

%

Reporting |

%Too

High |

%About

Right |

%Too

Low |

Net |

Index |

| Dec 2024 |

78 |

11.5 |

70.3 |

18.2 |

-6.7 |

46.7 |

| Nov 2024 |

77 |

10.6 |

75.5 |

13.9 |

-3.3 |

48.4 |

| Oct 2024 |

80 |

12.2 |

69.1 |

18.7 |

-6.5 |

46.8 |

| Sep 2024 |

76 |

13.2 |

73.6 |

13.2 |

0.0 |

50.0 |

Prices†

The ISM Prices Index registered 52.5 percent, 2.2 percentage points higher compared to the November reading of 50.3 percent, indicating raw materials prices increased for the third straight month in December after a decrease in September. Of the six largest manufacturing industries, three — Food, Beverage & Tobacco Products; Machinery; and Computer & Electronic Products — reported price increases in December. “The Prices Index indicated increasing prices in December for the third consecutive month, but at weak rates. Aluminum, basic chemicals, copper and natural gas registered increases, offset by steel, plastic resins and diesel fuel moving down in price. Fourteen percent of companies reported higher prices in December, compared to 12 percent in November,” says Fiore. A Prices Index above 52.8 percent, over time, is generally consistent with an increase in the Bureau of Labor Statistics (BLS) Producer Price Index for Intermediate Materials.

In December, the seven industries that reported paying increased prices for raw materials, in order, are: Primary Metals; Wood Products; Food, Beverage & Tobacco Products; Miscellaneous Manufacturing; Machinery; Computer & Electronic Products; and Electrical Equipment, Appliances & Components. The three industries report paying decreased prices for raw materials in December are: Plastics & Rubber Products; Chemical Products; and Fabricated Metal Products. Seven industries reported no change in prices in December as compared to November.

|

Prices |

%Higher |

%Same |

%Lower |

Net |

Index |

| Dec 2024 |

14.4 |

76.1 |

9.5 |

+4.9 |

52.5 |

| Nov 2024 |

12.2 |

76.1 |

11.7 |

+0.5 |

50.3 |

| Oct 2024 |

19.8 |

69.9 |

10.3 |

+9.5 |

54.8 |

| Sep 2024 |

12.9 |

70.7 |

16.4 |

-3.5 |

48.3 |

Backlog of Orders†

ISM’s Backlog of Orders Index registered 45.9 percent, an increase of 4.1 percentage points compared to the November reading of 41.8 percent, indicating order backlogs contracted for the 27th consecutive month after a 27-month period of expansion. Of the six largest manufacturing industries, two (Food, Beverage & Tobacco Products; and Computer & Electronic Products) reported expanded order backlogs in December. “In December, the index recorded its best performance since April 2024 (45.4 percent), as new orders coupled with stable production levels slowed the rate of declining backlogs,” says Fiore.

Of the 18 manufacturing industries, three reported growth in order backlogs in December: Food, Beverage & Tobacco Products; Computer & Electronic Products; and Electrical Equipment, Appliances & Components. The 10 industries reporting lower backlogs in December — in the following order — are: Textile Mills; Primary Metals; Printing & Related Support Activities; Furniture & Related Products; Plastics & Rubber Products; Wood Products; Machinery; Transportation Equipment; Chemical Products; and Miscellaneous Manufacturing.

Backlog of

Orders |

%

Reporting |

%Higher |

%Same |

%Lower |

Net |

Index |

| Dec 2024 |

91 |

14.9 |

62.0 |

23.1 |

-8.2 |

45.9 |

| Nov 2024 |

92 |

14.5 |

54.6 |

30.9 |

-16.4 |

41.8 |

| Oct 2024 |

93 |

14.1 |

56.4 |

29.5 |

-15.4 |

42.3 |

| Sep 2024 |

92 |

14.5 |

59.1 |

26.4 |

-11.9 |

44.1 |

New Export Orders†

ISM’s New Export Orders Index registered an “unchanged” reading of 50 percent in December, up 1.3 percentage points from November’s reading of 48.7 percent. “The New Export Orders Index reading indicates that export orders were ‘unchanged’ from last month, following six straight months of contraction. New export orders stabilized this month as international trading partners are showing signs of demand recovery as we enter 2025,” says Fiore.

The four industries reporting growth in new export orders in December are: Plastics & Rubber Products; Food, Beverage & Tobacco Products; Computer & Electronic Products; and Miscellaneous Manufacturing. The four industries reporting a decrease in new export orders in December are: Primary Metals; Transportation Equipment; Machinery; and Chemical Products. Eight industries reported no change in exports in December.

New Export

Orders |

%

Reporting |

%Higher |

%Same |

%Lower |

Net |

Index |

| Dec 2024 |

74 |

10.9 |

78.2 |

10.9 |

0.0 |

50.0 |

| Nov 2024 |

75 |

10.6 |

76.1 |

13.3 |

-2.7 |

48.7 |

| Oct 2024 |

74 |

7.7 |

75.6 |

16.7 |

-9.0 |

45.5 |

| Sep 2024 |

73 |

7.2 |

76.1 |

16.7 |

-9.5 |

45.3 |

Imports†

ISM’s Imports Index continued to indicate cooling in December; the reading of 49.7 percent is 2.1 percentage points higher compared to the reading of 47.6 reported in November. “Imports contracted for the seventh month in a row after five consecutive months of expansion, preceded by 14 consecutive months of contraction. Imports moved closer to growth as inventory constraints weaken and panelists act to better absorb any potential tariff impact in the future,” says Fiore.

The seven industries reporting an increase in import volumes in December, in order, are: Wood Products; Plastics & Rubber Products; Furniture & Related Products; Food, Beverage & Tobacco Products; Machinery; Electrical Equipment, Appliances & Components; and Computer & Electronic Products. The five industries that reported lower volumes of imports in December are: Paper Products; Printing & Related Support Activities; Primary Metals; Transportation Equipment; and Fabricated Metal Products.

| Imports |

%

Reporting |

%Higher |

%Same |

%Lower |

Net |

Index |

| Dec 2024 |

85 |

12.8 |

73.8 |

13.4 |

-0.6 |

49.7 |

| Nov 2024 |

83 |

10.2 |

74.8 |

15.0 |

-4.8 |

47.6 |

| Oct 2024 |

84 |

11.7 |

73.1 |

15.2 |

-3.5 |

48.3 |

| Sep 2024 |

82 |

10.2 |

76.2 |

13.6 |

-3.4 |

48.3 |

†The Supplier Deliveries, Customers’ Inventories, Prices, Backlog of Orders, New Export Orders, and Imports indexes do not meet the accepted criteria for seasonal adjustments.

Buying Policy

The average commitment lead time for Capital Expenditures in December was 175 days, an increase of five days compared to November. Average lead time in December for Production Materials was 81 days, an increase of two days compared to November. Average lead time for Maintenance, Repair and Operating (MRO) Supplies was 46 days, an increase of two days compared to November.

| Percent Reporting |

Capital

Expenditures |

Hand-to-

Mouth |

30 Days |

60 Days |

90 Days |

6 Months |

1 Year+ |

Average

Days |

| Dec 2024 |

14 |

5 |

8 |

15 |

30 |

28 |

175 |

| Nov 2024 |

16 |

4 |

9 |

15 |

29 |

27 |

170 |

| Oct 2024 |

16 |

5 |

12 |

12 |

28 |

27 |

168 |

| Sep 2024 |

16 |

3 |

10 |

13 |

30 |

28 |

174 |

| Percent Reporting |

|

Production

Materials |

Hand-to-

Mouth |

30 Days |

60 Days |

90 Days |

6 Months |

1 Year+ |

Average

Days |

|

| Dec 2024 |

7 |

25 |

28 |

27 |

8 |

5 |

81 |

|

| Nov 2024 |

8 |

24 |

28 |

27 |

9 |

4 |

79 |

|

| Oct 2024 |

9 |

25 |

26 |

26 |

9 |

5 |

81 |

|

| Sep 2024 |

7 |

26 |

28 |

27 |

7 |

5 |

80 |

|

| Percent Reporting |

| MRO Supplies |

Hand-to-

Mouth |

30 Days |

60 Days |

90 Days |

6 Months |

1 Year+ |

Average

Days |

| Dec 2024 |

30 |

35 |

16 |

13 |

5 |

1 |

46 |

| Nov 2024 |

30 |

34 |

17 |

13 |

6 |

0 |

44 |

| Oct 2024 |

30 |

34 |

18 |

12 |

5 |

1 |

46 |

| Sep 2024 |

27 |

37 |

19 |

11 |

5 |

1 |

46 |

Posted: January 3, 2025

Source: Institute for Supply Management

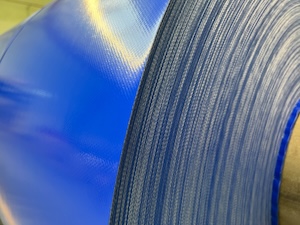

CARY, N.C. — January 7, 2025 — INDA, the Association of the Nonwoven Fabrics Industry, today announced that registration is open for the IDEA®25 International Conference and Exhibition on April 29-May 1, 2025, at the Miami Beach Convention Center in Florida.

CARY, N.C. — January 7, 2025 — INDA, the Association of the Nonwoven Fabrics Industry, today announced that registration is open for the IDEA®25 International Conference and Exhibition on April 29-May 1, 2025, at the Miami Beach Convention Center in Florida. For the first time at IDEA, the two-day conference will be dedicated exclusively to sustainability, recognizing its critical importance to the nonwovens industry. The conference will bring together C-suite leaders, business development professionals, sustainability managers, product developers, regulatory teams, sales, and marketing to advance “Nonwovens for a Healthier Planet.”

For the first time at IDEA, the two-day conference will be dedicated exclusively to sustainability, recognizing its critical importance to the nonwovens industry. The conference will bring together C-suite leaders, business development professionals, sustainability managers, product developers, regulatory teams, sales, and marketing to advance “Nonwovens for a Healthier Planet.”