CHRIST CHURCH, Barbados — January 23, 2025 — Gildan — an apparel manufacturer of quality, affordable basics, comfortable styles and iconic apparel — is pleased to showcase the latest styles and product innovations from its portfolio of brands — Gildan®, Comfort Colors®, American Apparel®, and its most recent addition under an exclusive licensing agreement for the printwear channel, Champion® — at the Impressions Expo Long Beach in California. The brands will be onsite at the three-day expo to feature the newest innovations, showcase recently launched collections, host interactive booth displays with live printing and giveaways and provide an exclusive sneak peek into 2026 styles.

CHRIST CHURCH, Barbados — January 23, 2025 — Gildan — an apparel manufacturer of quality, affordable basics, comfortable styles and iconic apparel — is pleased to showcase the latest styles and product innovations from its portfolio of brands — Gildan®, Comfort Colors®, American Apparel®, and its most recent addition under an exclusive licensing agreement for the printwear channel, Champion® — at the Impressions Expo Long Beach in California. The brands will be onsite at the three-day expo to feature the newest innovations, showcase recently launched collections, host interactive booth displays with live printing and giveaways and provide an exclusive sneak peek into 2026 styles.

“The innovations and styles we’re introducing across our brands underline and strengthen our position as the industry’s preferred choice for decorators,” says Emma Budzisz, Vice-President of Marketing at Gildan Activewear SRL. “We are confident that these updates will further support our growth ambitions as we continue implementing our Gildan Sustainable Growth strategy.”

“The innovations and styles we’re introducing across our brands underline and strengthen our position as the industry’s preferred choice for decorators,” says Emma Budzisz, Vice-President of Marketing at Gildan Activewear SRL. “We are confident that these updates will further support our growth ambitions as we continue implementing our Gildan Sustainable Growth strategy.”

Gildan®

Gildan®, the smart choice for decorators, is excited to announce new product innovations for 2025. The innovative Plasma Print Technology aims to enhance the direct-to-garment printing process by reducing the need for pre-treatment. This development is designed to offer softer fabrics, brighter colors, improved ink coverage, and enhanced print consistency. The brand’s Soft Cotton Technology, is a fabric innovation that redefines softness and comfort and will be incorporated in the brand’s new Light Cotton™ collection, offering customers a softer touch and improved printability qualities, all at the same durability and value as before.

Gildan will also debut new styles, including additions of 3000 and 3000B to the new Light Cotton collection, 75000, 19500 and 19000 to the Gildan Hammer Maxweight collection, as well as SF008 and SF100 to the Softstyle™ Midweight Fleece collection. With these, Gildan continues its legacy as the smart choice for decorators and printers alike.

Comfort Colors®

Comfort Colors® is celebrating 50 years of spreading good vibes as the soft, high-quality, garment-dyed ring-spun cotton shirts brand. To mark five decades of unbeatable comfort and endless nature-inspired hues, Comfort Colors® is introducing fresh new colors in their best-selling 3023CL and 6030 styles, along with new youth styles 1467Y and 1745Y as well as a cozy Fleece Dorm Blanket.

Tradeshow attendees can also expect a preview of the brand’s 2026 collection, featuring fresh silhouettes for women. Comfort Colors continues to celebrate the beauty and essence of Colors Inspired by Nature™ with its Pigment Pure™ dyeing and reactive hues in each cozy garment.

American Apparel®

Staying true to its roots, American Apparel® continues to craft premium apparel with its lineup of new colors in the iconic 2001 and 2001CVC styles and the introduction of the Super Heavyweight collection which offers customers a new, street-style oversized fit.

The brand will also feature its recently launched Logo collection, known for its effortless style and softness, available exclusively on Amazon for customers and decorators. With these, American Apparel® reaffirms its dedication to Crafting the Culture and shaping timeless memories for its customers with a blend of apparel and pop culture.

Champion®

Having partnered with Authentic Brands Group, the owner of the Champion® brand through a licensing agreement for the printwear channel, Gildan is pleased to present the brand’s confident, bold, and stylish collection, featuring authentic athletic apparel. Tradeshow attendees can explore the extensive collection, including the styles S450, S600, S650, S700, S790, S800, P800, P930, CO125, CO200, S101, RW01W, S149, T137, T425, T105, T453W, 8187, S162, which embody the Champion spirit of individuality and uniqueness in athletic apparel.

Posted: January 23, 2025

Source: Gildan

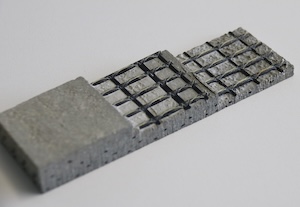

![]() ZÜRICH, Switzerland— January 24, 2025 — Based in Finland, Spinnova has developed patented technology for making textile fiber from wood pulp or waste, such as leather, textile or agricultural cropping waste, without harmful dissolving chemicals. The Spinnova technology uses a mechanical process which gives the fiber the look and feel of a natural cellulosic fiber such as cotton.

ZÜRICH, Switzerland— January 24, 2025 — Based in Finland, Spinnova has developed patented technology for making textile fiber from wood pulp or waste, such as leather, textile or agricultural cropping waste, without harmful dissolving chemicals. The Spinnova technology uses a mechanical process which gives the fiber the look and feel of a natural cellulosic fiber such as cotton.

For more information about Spinnova, please go to https://www.spinnova.com.

For more information about Spinnova, please go to https://www.spinnova.com.