BANGKOK, Thailand — October 19, 2021 — The Hygiene Fibers Group of Indorama Ventures (IVL) comes together at the Index Show in Geneva, October 19-22, to present an all-inclusive range of recycled and biodegradable solutions for Hygiene Fiber and Nonwoven applications.

The combination of polymers, technologies, processes and global reach supported by the Hygiene Fibers Group — one of three business segments that make up Indorama Ventures — positions it uniquely within the Hygiene industry to meet increasingly challenging market demand for innovative sustainable solutions within the hygiene sector. Across the six brands and companies that make up Hygiene Fibers Group — Auriga, Avgol, FiberVisions, Indorama Asia, Trevira and Wellman International — sustainability and supporting customers to achieve circular objectives is integral to all efforts and fundamental to the ethos of the Hygiene business segment.

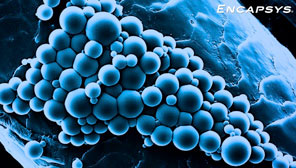

At the Index Show, the Hygiene Fibers Group will launch CiCLO®, a textile technology which allows polyester and other synthetic materials to biodegrade like natural materials do in wastewater treatment plant sludge, sea water and landfill conditions, reducing synthetic microfiber pollution generated during washing, and minimizing plastic accumulation in landfills caused by discarded textiles.

Involved in PET Recycling, IVL is fully committed to the delivery of a circular economy and also recognizes that alternative sustainable technologies, such as CiCLO® textile technology, provide valuable alternative solutions when recycling may not be possible. In line with the company’s commitment to support customers with high performance products, while also reducing the impact on the environment, several of the Hygiene Fibers brands, including Wellman International, Trevira GMBH and Auriga, have been working closely over the last 12 months with the IAM team and the CiCLO® technology. Developments have focused on PET and rPET staple fiber and filament sustainable solutions for applications where recycling is particularly challenging, such as Hygiene, Home Textiles and Automotive applications.

Strengthening the profile of biodegradable offerings within the Hygiene Fibers Group’s sustainability portfolio, Trevira will introduce a new range of bicomponent fibres based on PLA and PBS (polybutylene succinate) at the Index show. Both biopolymers offer an exceptional technological opportunity in terms of environmental care and sustainability, while delivering optimum performance. Equally to PLA, PBS is recyclable and up to 100-percent biodegradable under industrial conditions.

Efforts towards supporting customers to achieve circular objectives are a priority within the Hygiene Fibers Group. This is reflected in the recycled fibers expertise deployed across the segment. Four Hygiene Fibers Group brands, IVL Asia, Auriga, Trevira and Wellman International offer an extensive range of 100-percent recycled, accredited PET fibers, across a multitude of fiber and nonwovens applications. Through investments and evolving technological advancements, Wellman International, as pioneers in recycling technologies for over 50 years, has broadened the range of PET that can be processed into other PET applications towards achieving a circular economy. The segment’s rPET product portfolio is represented under the Deja™ brand platform, differentiated in the market by a performance-led suite of sustainable solutions that helps customers to achieve their sustainability targets, while also responding to end-consumers’ demand for transparency and environmental responsibility. All brands look forward to productive discussions at Index on how IVL Hygiene rPET fibers can help support customer objectives and targets.

The development and evolution of sustainable technologies is central to activity across IVL’s Hygiene Fibers Group, with particular focus on sustainable polyolefin solutions. FiberVisions and ES-FIBERVISIONS, leading Polyolefin mono and bico fiber brands and sister company Avgol, have partnered with UK-based Polymateria to commercially harness the innovative ‘biotransformation’ technology pioneered by Polymateria. The patented technology alters the properties of polyolefins to make them biodegradable in a natural process. Other polyolefin sustainable innovations within the Hygiene Fibers Group being featured at Index include biosurfactant and biocolourant developments being undertaken by the Avgol team with FiberVisons progressing sustainable design solutions, including lightweight, high performance, reduced carbon solutions. All developments are featured at Index and the team welcome the opportunity to explore how these developments can support customers sustainability goals.

Shachar Rachim CEO, Hygiene Fibers Group said: “Integrated within the IVL Hygiene Group is extensive knowledge, experience and a true commitment to Sustainability, which will be evident in the innovations and products being featured on our booth at the Index Show. This is reflective of the priority which we as a business attach to this fundamental issue. Within the IVL Hygiene Group, we take this responsibility very seriously and Sustainability is strategically embedded in all of our efforts’.

Posted October 18, 2021

Source: Indorama Ventures Public Company Limited (IVL)