Brands and consumers can work together to make the textile industry more sustainable.

Brands and consumers can work together to make the textile industry more sustainable.

By Puneet Goyal

Recent globalization has led to a greater number of people migrating to cities in search of better opportunities. This has led to a continuous surge in demand for natural resources like fossil fuels, wood, metals and cotton. Continuous and unchecked usage of these resources has led to their rapid depletion. Another major problem is an increase in piles of waste generated as byproducts in manufacturing processes. Solid waste disposal has become a serious problem in urban cities across the world, thereby pushing mankind towards sustainable initiatives. Sustainability implies meeting our current needs judiciously, and also keeping in mind the needs and demands of future generations, to achieve a balance between the two.

Pillars Of Sustainability

Sustainability is made up of three pillars — environment, economy and society. These three pillars also are informally called profit, people, and the planet. Each pillar plays a major role in categorizing the type of initiative taken by the corporations and brands. In recent times, it has become one of the major areas of concern because of the rapid increase in consumer awareness and availability of mass information online.

Environmental Sustainability

Environmental sustainability implies that natural resources within the earth’s environment are consumed by humans at a rate where they are able to replenish themselves. The environmental pillar often gets the most attention. Manufacturing industries and brands are constantly focusing on reducing their carbon footprints, packaging waste, water usage, and their overall effect on the environment. Corporations have discovered that these sustainable initiates also have a positive financial impact. For example, reducing the amount of material used in packaging usually reduces the overall expenditure on those materials.

Economic Sustainability

This pillar ensures that economic systems are intact and activities such as secure sources of livelihood are available to everyone across the globe. Also, people are able to maintain their independence and have access to the resources that they require to meet their daily needs.

Social Sustainability

Social sustainability takes into account that healthy communities have just leaders who treat everyone with equality and ensure labor, cultural and personal rights are respected. People are protected from discrimination. Universal human rights and basic necessities are attainable by all.

Why Sustainability Is Imperative

It is unrealistic to create a list of reasons why so many individuals, groups, and communities are working towards sustainability, because the motivations behind sustainability are often complex, personal, and diverse. Yet, for most people, sustainability boils down to the kind of future we are leaving for the next generation. Sustainability as a value is shared by many individuals and organizations who demonstrate this value in their policies, everyday activities and behaviors. These policies and activities play a vital role in deciding consumer choice. Common individuals also play a major role in developing current environmental and social circumstances by choosing greener alternatives.

Sustainability In Textiles

Sustainability in textiles implies consuming green clothing. For this, one has to rely on specific brands using fabrics from recycled materials or innovative natural fibers. At times, we may have heard to avoid certain types of cotton or wool and instead choose fibers such as lyocell or linen.

Brands And Manufacturer’s Responsibilities For Promoting Sustainability

Being a responsible brand in the textile industry in terms of sustainability is itself challenging.

Responsibility may mean a lot of things but essentially while classifying brands one should keep in mind the following:

- Global corporate standards for health and safety of environment and workers;

- Actions to enhance environmental performance such as reduced water usage and recycling programs, for example;

- Transparent and ethical sourcing policies for raw material as well as finished goods;

- A commitment to fair living wages for workers; and

- Clearly defined corporate sustainability strategies and practices.

Textile brands and manufacturers are taking initiatives towards sustainability. Some recent efforts include:

- H&M — created transparency rules for suppliers and provided details of its sustainability strategy in its annual sustainability report.

- Nike — set sustainability targets that include minimizing its environmental footprint through analyzing the supply chain to “use less, use better and use again.”

- ASOS — initiated a “Green Room” on its website that displays only ethically conscious brands that fit within its “sustainability criteria.”

- Fat Face — developed a company-wide code of conduct for its factories and a responsible sourcing commitment.

- Patagonia — A market leader in responsible fashion, the company has launched an innovative clothing reuse and recycle program.

Consumer’s Recent Shift Towards Sustainable Initiatives

Many non-profit organizations have come with innovative programs to promote sustainability in textiles by targeting consumers. Cotton Incorporated offers its Blue Jeans Go Green™ program, a social initiative designed to encourage consumers to recycle old denim garments. Started in 2006, the Blue Jeans Go Green program collects old denim, made from high cotton content, so it can be recycled back to its original fiber state and transformed into useful new products such as building insulation, thermal packaging insulation, pet bed inserts, and more. The #DenimStackChallenge encourages consumers to collect their old and used denim, take pictures of their denim “stacks,” and share them on social media, and then recycle those pieces they can no longer wear.

Since the Blue Jeans Go Green program began, more than 1,950 tons of denim have been diverted from landfills, and more than 3,900,000 pieces of denim have been recycled. In 2021 alone, more than 60,000 pieces of denim were collected in the first three quarters by individuals and retailers.

Among the consumers who have participated in the program, 80 percent said they decided to contribute because they’re “trying to be more sustainable or environmentally conscious.” Consumers also said they liked the fact that their denim goes toward helping communities. Consumers said participating in the Blue Jeans Go Green program “makes me feel like I have done something good”, and they would prefer to keep their unwanted denim items out of landfills.

Solution: Circular Economy

Solution: Circular Economy

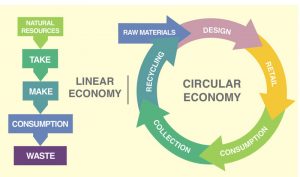

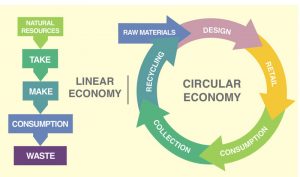

A circular economy or circularity is a production and consumption model. It involves sharing, leasing, reusing, repairing, refurbishing, and recycling existing materials and products for as long as possible. This aims to tackling global challenges like climate change, biodiversity loss, and waste generation. A circular economy is unlike a linear economy in which there is no recycling or reusing.

On World Cotton Day last October, PacSun announced its involvement with Cotton Incorporated’s Blue Jeans Go Green program to launch the “PacDenim for Good” initiative.

“As a brand dedicated to inspiring positive development with fashion, we firmly believe that small changes today will result in a better tomorrow,” said Brie Olson, PacSun president. “We are excited to introduce PacDenim for Good as a continuation of our journey to a more sustainable future.”

More than 2 out of 5 consumers — 43 percent — say they donate their old jeans they no longer plan to wear, according to the 2020 Cotton Incorporated’s Lifestyle Monitor™ Survey. That’s followed by 18 percent of consumers who plan to give them away, 12 percent who intend to throw them away, and 9 percent who expect to reuse them in a different way, such as for cleaning rags or craft projects.

Bottom Line

Natural resources available in the earth’s environment are scarce and their judicious use is imperative. Sustainability plays a vital role in this judicious use. Brands and consumers must come together and work towards a better future. Shifting towards greener alternatives can essentially reduce carbon footprints. Initiatives like Blue Jeans Go Green have successfully illustrated this. Another major solution is the circular economy in which emphasizes reducing and recycling waste materials.

Editor’s Note: Puneet Goyal is chief representative – polyester, for RIL USA Inc., a division of India-based Reliance Industries Ltd.

January/February 2022