WASHINGTON — March 6, 2024 — The Coalition to Close the De Minimis Loophole launched today, representing thousands of voices, from the families of victims of fentanyl fatalities and nonprofit and nonpartisan organizations to labor unions, domestic law enforcement associations, domestic manufacturers, and business associations.

The coalition was formed to amplify the urgent need to reform a loophole in federal law known as Section 321, which allows packages valued at less than $800 to enter the United States without facing any taxes, fees or inspection. As a result, this cripples domestic manufacturers and workers, undermines retailers, strains law enforcement resources, and facilitates the free flow of illegal and dangerous products and illicit drugs, particularly fentanyl—the leading cause of death for people ages 18-49. The Coalition is calling on Congress and the Administration to immediately close this dangerous loophole.

Among its key objectives, the Coalition is dedicated to increasing awareness and education around the harmful impacts of de minimis, a loophole being exploited by China and other foreign entities to facilitate a flood of fentanyl and other illicit drugs, products made with slave labor, and counterfeit and toxic consumer products into the U.S. market.

Rep. Earl Blumenauer (D-Ore.), ranking member of the House Ways and Means Trade Subcommittee, who has been leading an effort on Capitol Hill to reform the de minimis loophole in U.S. trade law, helped announce the formal launch of the Coalition at a press conference today.

“The coalition we have assembled is a testament to the mounting pressure to close the de minimis loophole. De minimis is not just a threat to American businesses and consumers, as if that weren’t enough, but it is increasingly contributing to the fentanyl crisis ravaging our communities. It is past time for Congress to act. We will not take ‘no’ for an answer,” Congressman Blumenauer said.

The Congressman has introduced bipartisan legislation known as the Import Security and Fairness Act, that would block non-market economies — namely China — from exploiting the de minimis threshold and would require U.S. Customs and Border Protection (CBP) to collect more information on de minimis shipments in order to better understand the scope of de minimis abuse and inform other necessary reforms.

“As the United States’ trade deficit continues to grow and global threats continue to emerge, we must not continue transferring wealth to an adversary like China,” said Congressman Neal Dunn (R-Fla.), who is a co-sponsor of the legislation. “Our current de minimis tariff incentivizes the ‘gaming’ of American laws. Right now, China’s doing a shell game with their exports to the U.S. by laundering them thru through Mexico, thereby dodging all duties. We must stop this! I look forward to working with this coalition to ensure that we protect Americans and American businesses.”

National Council of Textile Organizations (NCTO) President and CEO Kim Glas said: “De minimis is not just a textile issue — it’s an issue impacting us all — which is why this broad, diverse coalition has been formed to amplify our collective voices in the fight to get immediate, substantial and consequential change. We know this coalition will continue to grow and build given the urgency impacting everyone. We applaud Congressman Blumenauer for his tremendous leadership and Congressman Dunn, Congressman Bishop and Congresswoman DeLauro and many others who share this sense of urgency that we need to close de minimis now. Closing this loophole will simultaneously assist law enforcement battle the deadly fentanyl and broader illicit drug crisis while also assisting U.S. businesses to operate on a more level playing field with competitors overseas. We urge others in Congress and the Administration to support the effort and immediately close de minimis.”

In 2023, the nearly century-old de minimis rule astonishingly allowed nearly three million packages a day (rising to 1 billion a year) to enter the U.S. largely uninspected and duty free — 60 percent of which originate from China, notorious for products made with slave labor and counterfeits, and the source of the majority of precursor chemicals used to make illicit fentanyl.

“Customs officials want to — and know how to — protect Americans from unlawful goods imports and illicit drug,” said Michael Stumo, CEO of the Coalition for a Prosperous America. “But Congress capitulated to FedEx and UPS to create high volume lawlessness enabling Shein, TEMU and foreign criminal organizations to ship goods to U.S. customers and drug dealers. Both Congress and President Biden have the power to close this loophole, save an estimated 20,000 lives per year and protect U.S. workers and businesses who obey our laws. CPA supports Congressman Blumenauer’s legislation that would exclude China from de minimis as a major step to rising the problem.”

According to (CBP), imports using the de minimis loophole include “high-risk shipments that may contain narcotics, merchandise that pose a risk to public safety, counterfeits, or other contraband.” The agency recently stated that it “continues to see bad actors seeking to exploit the increasing volumes of de minimis shipments to transit illicit goods, including fentanyl and the precursors and paraphernalia used to manufacture it.”

The impact has been devastating:

- CDC data predicts more than 112,000 drug-related deaths in the past year, with more than 70,000 caused by illicit fentanyl, record numbers to which de minimis is actively contributing.

- Ten U.S. textile plants have closed and hundreds of employees have been laid off, due in part to the loophole acting as a back door to a flood of low-priced, subsidized imports from China often containing cotton made with forced labor.

“In June 2018, my daughter Ashley Romero died from fentanyl poisoning. Ashley was 32 years old. She was a mother, daughter, sister, and friend to many. Ashley did not know about illicit fentanyl, nor did she know that the pill she took that looked just like her medication would take her life,” said Andrea Thomas, founder of Voices for Awareness/Facing Fentanyl. “Ashley’s death has been devastating for our family. Fentanyl is flooding into our country and taking a life every five minutes. Fentanyl has become so readily available that it has killed more than 112,000 Americans in 2023 alone. It can be shipped straight from China and frequently with purities of more than 90 percent, according to the Department of Homeland Security (DHS). What makes this shipping so easy is a loophole in U.S. customs law known as ‘de minimis.’ Under de minimis, millions of small international mail packages are mailed directly to U.S. consumers daily, completely bypassing federal scrutiny. This loophole has contributed to the public health crisis our nation is facing. We have joined this coalition to close this dangerous loophole. It will help save lives.”

“We have long fought for resources to support law enforcement’s efforts to combat fentanyl and its analogues,” said Bill Johnson, executive director, National Association of Police Organizations (NAPO). “Closing the de minimis loophole would help staunch the surge of illicit narcotics that are exploiting this exemption to wreak havoc across the country and protect and safeguard the lives of our children, families and friends. In this moment of crisis, we need to use every weapon we have to curb the unfettered flow of imported fentanyl. The work of this coalition is incredibly important, and we are proud to be a part of it.”

“The de minimis loophole means that our own trade laws are granting bad actors like SHEIN and Temu an outrageous advantage over American manufacturers,” said Alliance for American Manufacturing (AAM) President Scott Paul. “These Chinese companies have built billion-dollar businesses by exploiting de minimis, hooking American consumers on below-bargain-basement prices and supercharging a retail race to the bottom. There’s a very real cost hidden behind these cheap wares, and it’s paid by the men and women on the factory floor both here and abroad. The de minimis provision invites importers to cheat the system and to exploit their workers. The United States must close this loophole now.”

Lori Wallach, director of Rethink Trade said, “We simply cannot continue with the current de minimis loophole situation of 3 million packages of imports ordered online, entering the U.S. daily without inspection, and dodging trade-cheating fines, normal tariffs and taxes and the ban on Chinese forced labor goods, which destroys U.S. producers, puts brick-and-mortar retailers at an unfair disadvantage, and exposes American consumers to dangerous and fake goods delivered to their doorsteps.”

The Coalition’s request for commonsense reform is quickly achievable either through legislation or the administration’s executive authority.

For more information about the impact of the de minimis loophole, click here.

Coalition Members

- AFL-CIO

- Alliance for American Manufacturing

- Coalition for a Prosperous America

- Citizens Trade Campaign

- Families Against Fentanyl

- Fentanyl Victims Network of North Carolina

- International Association of Chiefs of Police

- Kelsie’s Cause

- Lost Voices of Fentanyl

- National Association of Police Organizations

- National Bicycle Dealers Association

- National Council of Textile Organizations

- National Crime Prevention Council

- National Sheriffs’ Association

- New Balance

- PeopleForBikes.org

- Rethink Trade

- Service Employees International Union

- Shatterproof

- Sherrill Manufacturing

- Specialized Bikes

- United Steelworkers

- Victims of Illicit Drugs,

- Voices for Awareness / Facing Fentanyl

- Workers United

Posted: March 6, 2024

Source: National Council of Textile Organizations (NCTO)

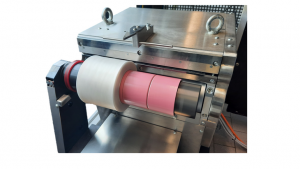

WATTWIL, Switzerland — March 7, 2024 — Unique technology for creating advanced technical textiles with exquisite characteristics will be featured at the upcoming Techtextil in Germany. Heberlein, the leading supplier of air interlacing and air texturing jets, plans to convince visitors to the event with critical components — such as the latest PolyJet-TG-3 — that can influence both yarn properties and processes.

WATTWIL, Switzerland — March 7, 2024 — Unique technology for creating advanced technical textiles with exquisite characteristics will be featured at the upcoming Techtextil in Germany. Heberlein, the leading supplier of air interlacing and air texturing jets, plans to convince visitors to the event with critical components — such as the latest PolyJet-TG-3 — that can influence both yarn properties and processes.