media.Filtration is divided into two broad classifications gaseous filtration and liquid

filtration. The proper filtering medium must be selected based on the material to be filtered, the

operating environment and the actual operating conditions. There is no universal fiber for

filtration. Neither is there a single fibrous or textile form suitable for every type of

filtration.The food and beverage industry is diverse, offering many opportunities for filtration

products. Filtration is important in dairy, meat, poultry, alcoholic beverages, soft drinks and

bottled water. The largest single application for beverages is beer filtration. Filtration is one

of the key unit operations in the manufacture of most types of basic raw materials and in the

production of most industrial and commercial products. Choosing The Filter MediumFollowing are

some of the major criteria that must be met in selecting the proper filter medium for a specific

application:Which is the most valuable component the filtrate or the filtered streamWhat is the

particle size to be retained by the mediumWhat is the permeability of the clean filtration

mediumWhat is the solids-holding capacity of the filtering medium, and what is the resistance of

the filtering medium to the passage of the filtered streamWhat is the physical state of the

suspension to be filtered, and what is the chemical constitution and temperatureThe choice of a

filter design for a given process depends on some of the following factors:the properties of the

solids to be removed and their concentration;particle size and shape as well as the properties of

the fluid;the quantity of material to be handled;whether the solid or the liquid, or both, are to

be retained after filtration;whether the filtrate must be washed; andwhether the filtration process

should be batch or continuous. Bag Filters For Liquid FiltrationBag filters have become more

popular for liquid filtration for process filtration and for hydraulic and lubricating filtration.

Polypropylene is the favored material for most liquid filtration because of its chemical resistance

and competitive price. Nonwovens For Protecting Membrane FiltersThe use of reverse osmosis is

growing by about 12 percent per year, gas separation types are growing by about 12 percent per

year, and electrodialysis is growing by about 8 percent per year.Polymeric microporous membranes of

cellulose acetate, polysulfone, polyvinylidene fluoride, acrylonitrile polymers and nylon are used

in chemical, pharmaceutical, food processing and waste treatment operations. Submicronic particles

must be removed from fluid process streams in these operations.Membrane filtration is the

separation of the components of a pressurized fluid, effected by polymeric or inorganic membranes.

The pores of the membrane are so small that significant fluid pressure is required to drive the

liquid through them.The pressure required varies inversely with the size of the pores. These

membranes have pores so small that they will plug and blind off instantly unless they are run in

the crossflow mode.Unlike traditional filtration, in membrane filtration, all the influent does not

pass through the media, but instead is split into the permeate (filtrate) and concentrate streams.

The concentrate stream flows parallel to the membrane, hence the term crossflow.The crossflow

membrane is a pressure-driven process in which the semipermeable medium acts as a surface filter to

split the feed stream into two effluents a purified stream and a stream concentrated in solutes too

large to pass through the pores of the particular membrane.Moving from the smallest to the largest

pore sizes, there are four categories of membrane filters.reverse osmosis (RO)nanofiltration

(NF)ultrafiltration (UF)microfiltration (MF)Reverse osmosis effects separation of small solutes,

including salts with ionic radii in the Angstrom ( range. The exact mechanism of rejection in RO is

more complex than in UF and MF.Nanofiltration is a term that was coined in the late 1980s to define

membranes that were already in use and were referred to as loose RO. They have pores close to one

nanometer in diameter (1- and effect partial salt rejection.NF membranes pass a higher percentage

of monovalent salt ions than divalent or trivalent ions. Nanofiltration membranes span the gap

between RO and UF classes of membranes. Ultrafiltration standards have been developed under ASTM

Standard D-1129, but no such official definition yet exists for reverse osmosis or

nanofiltration.Microfiltration is understood as the fine end of particle filtration, with pores

from 0.1 to 1 micron in diameter. MF membranes have pores two to five orders of magnitude larger

than the other classes.MF media are actually membranes and can be run in the crossflow as well as

in the normal flow mode. This can provide longer media life. In order for the membrane filter

systems to work properly, membrane fouling must be prevented.In membrane filtration, nonwovens can

play an important adjunct role. Some of the functions of nonwovens in membrane filtration systems

follow.protection during manufactureprotection and support during testingpleat separation for fluid

distributionpleat support to prevent collapseprefiltrationThe membrane films used are usually thin

and often in the range of 4 to 6 mils in thickness. While many of these membranes have good

chemical resistance and tensile strength, they are susceptible to puncture, damage from abrasion

and fatigue failure from flexing.Also, the membranes must be protected during fabrication into

cartridges and other forms. To protect the membranes during fabrication, they are often sandwiched

between two or more layers of nonwoven material. The nonwovens are typically polypropylene or

polyester.Extruded nettings as well as spunbonds and meltblowns are used extensively as protective

media.Polypropylene is commonly used because of its broad chemical compatibility and low cost.

Polyester provides a better combination when used with nylon membranes because of the higher

melting temperatures of the two materials. Nonwovens made from virgin resins with minimal additives

are required in processes where materials must meet FDA requirements.Care must be taken when using

meltblown nonwovens to prevent shedding of particles, particularly with finer denier meltblowns.

Often meltblowns will be calendered to prevent fiber shedding.

Downstream Nonwoven LayerA layer of nonwoven material adds structural support to the

folded membrane and must allow the fluid to move out of the pleat. This becomes more important as

differential pressure increases with contaminant buildup, increased fluid velocity or increased

fluid viscosity.Spunbonds are very suitable for the downstream layer because of their higher

strength and freedom from fiber shedding. Extruded nettings are also used, but they are thicker

than spunbonds. Upstream Nonwovens LayerIt is important to maintain proper fluid flow dynamics

above the membrane. The upstream nonwoven layer must keep the flow channels open between adjacent

pleats. Without support from a nonwoven layer, adjacent pleats may pinch together and impede fluid

flow. The upstream layer reduces the particle contaminant load on the final membrane filter. Proper

prefiltration greatly enhances the filtration performance of the membrane filter.The major

objective of the prefilter is to remove large, oversized particles so that the narrow pores of the

membrane filter do not become prematurely clogged. Important parameters for selecting a prefilter

are mean flow, pore size, pore size distribution and bubble point. The mean pore size correlates

well with filter retention efficiency. A narrow pore size is usually preferable. Generally, a

separate prefilter unit with nonwoven media is preferable. A separate prefilter can extend the use

of the final membrane filter by up to two times its normal life.There are some requirements for

nonwovens used with membrane filtration systems (See Figure 1). Benefit Of

Pre-FiltrationOsmonics SPIRALTEK® rolled filter medium with a spiral-wound design creates a

tangential crossflow motion that sweeps particulate across the medium and traps contaminants in

special nonpermeable sections, rather than in the medium itself. Rolled filters, much like pleated

filters, are made with different types of polymer membrane.Some of the following applications use

prefiltration systems based on the Osmonics SPIRALTEK rolled filter medium:Magnetic Media

Filtration Rolled filters provide the sharp cutoff to separate oversized particles from metal oxide

slurry. They also help to eliminate gel slugs.Specialty Inks Inks used for ink-jet printers,

ballpoint and roller pens and other specialty uses require highly efficient filters that can handle

viscous fluids and achieve the fine separation of contaminants from pigments. Rolled filters work

well in these applications.Biotechnology In processing blood serums, or biological extracts,

removal of unwanted bacteria, protein and other materials is essential. The ability of rolled

filters to hold a large volume of particulate is very beneficial. They also help to increase the

longevity of downstream sterilizing filters.Fermentation Broths In pharmaceutical and beverage

production, enzymes have to be removed once they have completed their work. Rolled filters, because

of their holding capacity, help to improve the efficiency of downstream membrane

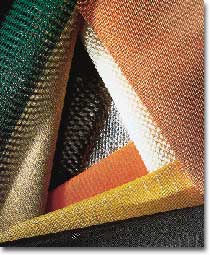

filtration. Dry-Gas FiltrationFor many years, woven fabrics were the most typical media, but

during the last 20 years, nonwovens have become the dominant filtration media.A major advantage of

nonwovens is versatility, since almost all major types of nonwovens can be used alone or in

combination in some type of filtration application.For air and hot-gas filtration applications,

there was earlier acceptance of needlepunched nonwovens in Europe than in the United States. This

is no longer the case. Higher-speed needlelooms, improved needles, high-temperature resistant

fibers and specialized fabric finishes have broadened the uses of needlefelts in both dry and wet

filtration. Needlefelts can be engineered to provide varied pressure drops and dirt holding

capacity.Polyester fibers are important for dry-gas filtration for use up to 275°F (135°C). Where

higher temperatures are required, fiberglass, DuPonts Nomex®, PPS (polyphenylene sulfide) and

Inspecs P84® polyimide fibers are used.Polypropylene is limited in dry-gas filtration to areas

where only relatively low temperatures are encountered. This excludes its use from baghouse

installations for power generation plants, as well as asphalt-, cement- and metal-processing

installations.However, polypropylene use is growing in applications for clean rooms and hospital

operating rooms, for which polypropylene filter media are available in a wide range of types from

bulky to paper-like structures. Filters For Gaseous FiltrationClass A filters are for coarse

dust and can even retain 60-micron particles. Class A filters are not suitable for filtering

sub-micron particles.Class B filters cover a wide range of efficiencies for removing sub-micron

particles. They are often used in the form of bags supported on a metal framework, or as

cartridges. They are commonly used as filters for air conditioning systems or as prefilters for

Class C filters.Class C or HEPA (High Efficiency Particulate Air) filters are specifically designed

to deal with very fine particles at low loadings. They are typically used in combination with a

Class B filter as a prefilter.Typical applications for Class C filters are electronic and

pharmaceutical clean-room manufacturing and fermentation processing.

Collection Mechanism In Dry-Gas FiltrationIn dry-gas filtration, particulates are

collected by three mechanisms direct interception, impaction and diffusion.In collection by

impaction, the particles have so much inertia that they cannot follow the streamline around the

fiber; thus they impact on its surface. The mechanism involves a collision of the particle on the

barrier. Another mechanism involves particle interception. In this case, the particles have less

inertia and can barely follow the streamlines around the obstruction. Even if it doesnt actually

touch the fiber, the particle is immersed in the viscous stream around the barrier, which will be

enough to slow it down so it will graze the barrier and stop. When this happens, the porosity of

the filter medium decreases and the true filtering surface begins to form.The third collection

mechanism is important for particles that are below 1 micron in aerodynamic diameter. Diffusion is

considered immaterial for particles with diameters smaller than 0.1 micron, which is in the

Brownian motion range. In this case, the particles are so small that their individual motion can be

affected by a collision on a molecular or atomic level.Other important factors are electrostatic

attraction and gravitational settling. As the particle loading in a filter increases, the

collection efficiency increases, but so does the pressure drop across the filtering unit. The

pressure drop is used to monitor the condition of the filter and to determine when it needs to be

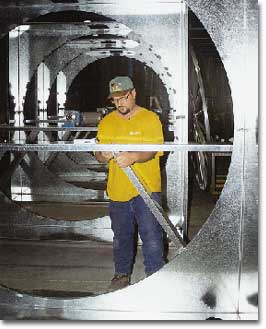

cleaned or replaced. Baghouse FiltrationsOne of the most common uses of baghouses is in the

electric utility industry where coal is used. A baghouse is a large metal box divided into two

functional areas. One area, the dirty-air plenum, may be a part of the baghouse proper, or it may

take the form of a gas-distribution manifold.The function of the dirty-air plenum is to distribute

the incoming gas evenly to the filtering elements or bags. The clean-air plenum is part of the

baghouse where recombination of the air from each of the individual bags takes place. The interface

separating clean-air and dirty-air plenums is the filtering medium or bags. The baghouse hopper is

a receptacle for collected particulate materials and is part of the dirty-air plenum.As discussed

in the previous section, the filter mechanisms involved in removing particles from a fluidized gas

stream are impaction, interception and diffusion. These mechanisms are responsible for the

collision of a particle on a target (the filter fabric) and are of paramount importance when the

baghouse is first brought on-line and the filtering elements are still clean.After a short time,

however, the bags become caked with a layer of flyash, and the dust cake actually becomes the

filtering medium. No matter how vigorously the bags are shaken, collapsed or pulsed, a residual

dust cake is retained after each cleaning, and the bags now act mainly as a matrix to support the

flyash. Classification Of BaghousesBaghouses are characterized and identified by the method

used to remove flyash from the bags. The bags in shaker-type units are suspended from a structural

framework, which is supported in such a way that it is free to oscillate when driven by a small

electric motor. Periodically, a damper isolates a compartment of the baghouse so that no air flows

into it. The bags in that compartment are then shaken for about a minute, during which time the

collected dust cake is dislodged from the bags. The dust falls into the hopper and is later

removed.Reverse-flow baghouses are equipped with an auxiliary fan that forces air through the bags

in an isolated compartment with the airflow in the opposite direction to filtration. The backwash

action collapses the bags and fractures the dust cake. When the bag is reinflated by being brought

back on-line, the fractured dust cake is dislodged into the hopper. If the unit operates under

suction (that is, if the main process fan is located on the clean side of the baghouse), the

reduced pressure in the baghouse may eliminate the need for an auxiliary fan. Some units combine

shaking and reverse-flow cleaning in the same unit.Reverse-pulse baghouses use a short pulse of

compressed air directed from the top to the bottom of the bag. This primary pulse usually lasts

less than a tenth of a second and aspirates secondary air as it passes through a nozzle or venturi.

The resulting air mass expands the bag and casts off the collected flyash. Shaker and reverse flow

units collect flyash on the inside of the bags, while reverse-pulse units collect flyash on the

outside of the bags.Baghouses have some practical limitations. Most bags have rather

low-temperature capabilities, ranging from 180°F to 300°F and above. Thus a practical limitation

exists when using fabrics able to withstand air-preheater outlet temperatures of 300°F and above.

Abrasion is a natural phenomenon that results from contact with flyash-laden gases. Some wear on

the filter bags occurs when flyash strikes a bag tangentially.The destruction of a bag from

chemical attack is generally due to misoperation. Processes that evolve gases at elevated

temperatures frequently produce water vapor and acid radicals, which at the acids dewpoint will

concentrate into a liquid. The acid dewpoint depends on the concentration of the constituents in

the gas, and it is almost impossible to predict.The bags tend to wear out with age. After hundreds

of cleaning cycles, the fabric weakens and will ultimately fail. The better the bag maintenance and

the better the equipment design and materials selection, the longer the bag will last.

Overall Trends In FiltrationNonwovens will continue to grow in importance. Higher

performance requirements for filtration systems are being driven by industry needs for improved

productivity and by stricter environmental requirements. The ability to engineer nonwoven materials

to meet these more stringent requirements is responsible for the growing use of all major types of

nonwovens in filtration applications. The use of automotive cabin filters is now a growing market

for nonwovens. Greater household use of drinking water filter systems and home air and household

cleaning devices present good growth potential for nonwovens. In wet filtration uses, polypropylene

will continue to be the dominant material because of its superior chemical resistance and

relatively low material cost.Meltblown nonwoven use in filtration is expected to continue to grow

by more than 8 percent per year over the next five years. Meltblown technology providing higher

strength webs is now under development and will further improve its versatility as a filtration

medium. Spunbond nonwovens will also show healthy growth in filtration, both alone and in

combination with meltblown materials. Needlepunch nonwovens continue to improve their performance,

particularly for more demanding dry-gas filtration applications based on improved manufacturing

technology.In wet filtration, needlepunched and meltblown combination fabrics are growing in

importance. Dry-laid nonwovens have lost some market share to spunbonds, but higher carding speeds

and improved thermal bonding techniques will help stabilize their position in filtration

applications.Use of specialty fibers will grow in filtration. Governmental clean air requirements

are boosting the use of high-temperature resistant fiber such as DuPonts Nomex, Inspecs P84, BASFs

Basofil® and PPS for industrial and utility systems. The use of fibers that incorporate additional

functions, such as antistatic and antifungal properties, is growing.There will be greater use of

fabric functional finishes. Use of additives and treatments is growing. The use of materials in the

form of finishes or microporous film laminates of silicone or fluorocarbons, which provide better

cake release properties, will continue to grow. The application of selective absorbents, such as

carbon and zeolite, to filter media is another important trend. The formation of electrets in

filter media to improve efficiency has now been widely commercialized.There will be major areas of

growth for nonwovens in filtration. Reverse osmosis is a growing industrial process for a wide

range of industries including food, pharmaceutical and microelectronics, and it will require

nonwoven filtration media for prefiltration of liquids. There is a growing need for nonwovens of

greater uniformity for use as casting support for membrane filters.Nonwoven use will not only grow

in automotive and household applications, but will become better known to the public because of

these growing uses.

August 2000