Electronic ArchivingOne of the most important decision points in implementing digital asset

management solutions (DAM) is also one of the most frequently overlooked: Who are your users and

how do they work Their technical level, their comfort with existing platforms and networks, as well

as their current workflow will all be major factors in the success, or failure, of a new system.

Champions and evangelists within the various departments of an enterprise are often critical to the

success of this kind of new technology.Once the personnel and technical issues are addressed,

workflow will define the process. In most cases, applications dictating workflow should be avoided.

Instead, efficiencies should come from the automation of proven workflow tasks. Of course,

emulating poor workflow will only let your staff be inefficient more quickly.Having already

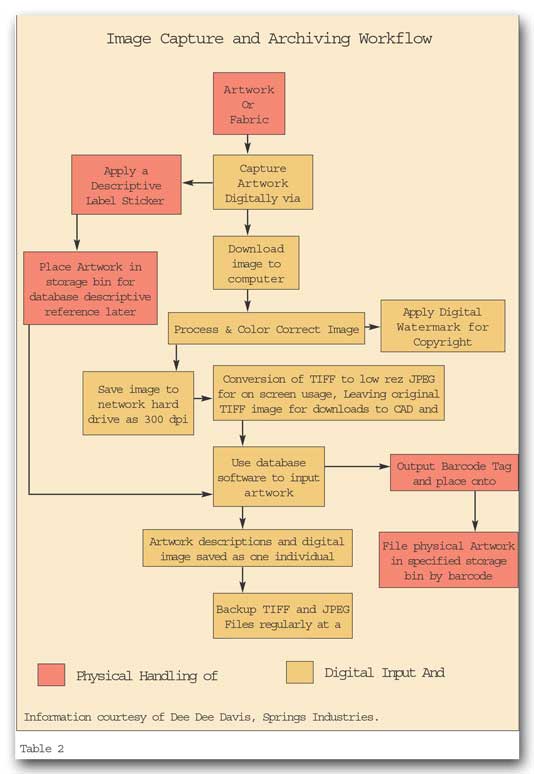

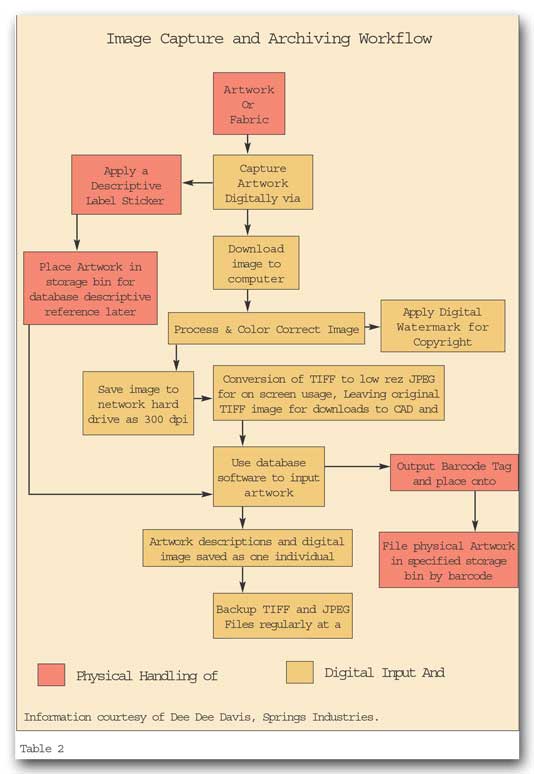

identified the goals of your DAM system, step number two in the planning stage is to draw a

flowchart of your current imaging and storage processes. Identify what you like or dont like about

your current workflow, and map out the recommended changes. This step should include participation

from any and all employees involved in the process, as they will all be affected by any changes

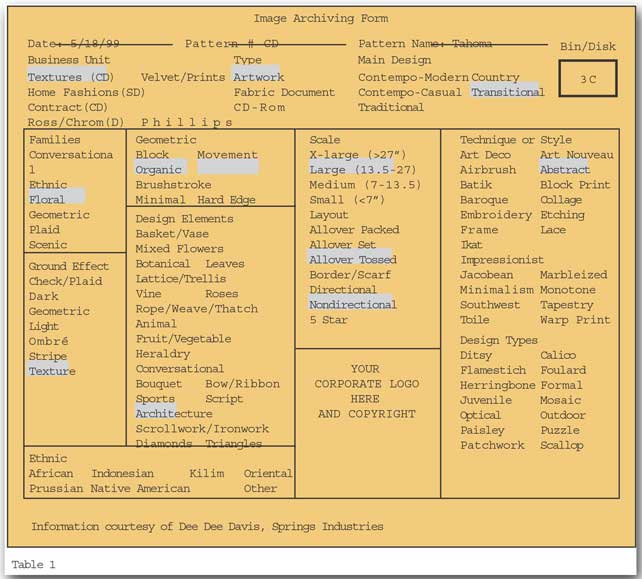

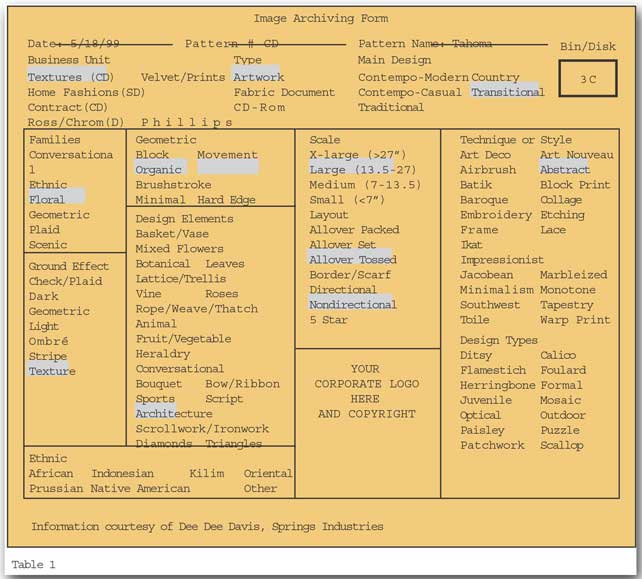

that are made.The next step is to create the attributes and keywords that will be supported by the

database (See Table 1). Attributes include categories such as business unit, type of asset, design

family, ground effect, geometry, design elements, scale, layout, technique or style, etc. Within

each of these categories, your users can identify keywords they might use when looking for a

particular type of artwork, such as floral, plaid, stripe, directional, impressionist, etc.Dee Dee

Davis, a CAD designer for Springs Industries, Fort Mill, S.C., advises that all departments needing

to use the archived files be included in this developmental stage, as classifications used by the

design department are often different from classifications and descriptions needed by other

departments in the company.

System Design PlanningNow you are ready for your system design plan, which will

identify how equipment pieces will need to be connected to one another. Some things to consider

are:How will non-digital art work be digitized, what equipment does it require and who will do

itWho will administer the archiving and who will have access to the filesWhat file formats need to

be saved in order to support various departments andIf you need a variety of formats for the

re-purposing of the files, will this be done at the same time of archiving or at a later date as

neededA map of the the new workflow should identify who does what, when they do it and how they do

it. (See Table 2.)The final step is to identify and develop the system standards that will identify

workflow issues such as file names, versions, folders, directories and servers. Failure to do so

will simply undermine the system and make it difficult to locate the correct version of a file.

Digitizing Traditional FabricsWhile archiving digitally generated artwork is fairly

straightforward, archiving the fabric samples and hand-drawn artwork that has been collected for

many years provides for some unique challenges and opportunities. Not only will digitizing artwork

make it easier to find, use and re-purpose, but archiving your artwork can also prove to be

valuable for an insurance claim in the event of fire or theft.As it is with the implementation of a

DAM system, you must determine your objectives before digitizing any artwork. There are four

quality standards that need to be considered for the use of your digital files:Product development

and pre-publishing reference;Intra-company report enhancement;Business to business for sales and

marketing; andDirect to consumer e-commerce. Your goals will establish the quality standards,

resolution and file formats for the digital files.While there are several capture devices to

consider for use in digitizing artwork, including digital cameras, flat-bed scanners and drum

scanners, most experts agree that a high-end digital camera is the best solution for the broad

range of texture, repeat size and color challenges that the textile industry presents. Capturing

artwork on a conventional camera and converting the slides or negatives to digital data is not

recommended, as there are too many variables in the conversion process that can cause degradation

of the image in both quality and color. Also, digital photography is both less expensive and faster

than conventional photography, which requires a series of time consuming and costly steps to get to

the digital file format.Another advantage to using photography over scanning is the ability to

control the lighting with the use of a camera. Scanners use only one light source that scans the

entire image, often missing nuances of special textures, yarns, finishes and colors.The use of a

camera will allow you to use multiple lighting sources that can be modified to highlight the

features of a variety of fabrics. In controlling the light source, you can also minimize the effect

of the fabric construction while trying to capture just the print.While there are software

applications such as Pointcarrrom Monarch that will allow you to remove the fabric construction

from a print, this is a step that can be avoided by obtaining a proper capture to start.Digital

cameras range in price from $500 to $25,000. The less expensive cameras are not as color accurate,

capture less data and are prone to digital noise that will create unacceptable artifacts and

mottled solid colors.The best-of-breed for low-end digital cameras, according to Richard Lerner,

president of RSL Digital, New York, is the new Nikon Coolpix. This camera includes many attributes

of the high-end cameras, including a flash sync for setting off studio strobes, excellent color

contrast and balance controls, and it works well in a number of automatic modes. The Right

EquipmentYou should review your workflow and processing time when evaluating digital cameras for

your company.Using a low-end camera is like trying to pass a lot of data on a floppy disk, said

Randy Parker, president of Digital Images, Research Triangle Park, N.C. You are constantly

performing sneaker net, and are required to run back and forth between the camera, which has

limited storage capacity, and the computers hard drive. High-end digital cameras have a direct SCSI

connection to the computer that will eliminate the need for repetitive data transfers. If you are

capturing a lot of images, this capability alone will more than offset the cost of the more

expensive camera.The digital files will range in size from 2 MB to 25 MB or more depending on the

physical size and intended use of the artwork. Resolution requirements range from 72 dots per inch

(dpi) for images to be viewed only on a computer screen, 150-300 dpi for printing to fabrics

(contingent on the type of fabric and amount of color coverage) and 300 dpi for printing to press

for sales and marketing materials. The rule of thumb is to capture a minimum of the same number of

dots per inch as the line screen of the output device, up to a maximum of twice the line screen.DAM

is not just about having the proper equipment, software and workflow, but about having qualified

talent to produce and manage the archiving process. Digital photography is an art in the same way

that CAD is an art. Buying the requisite tools does not compensate for the skillset needed to

produce quality archives. Budget ConsiderationsBudget will play an important role in your

decision regarding appropriate hardware, storage, backup, and communications infrastructure. DAM

software solutions come in many different packages, from a per seat basis for client licenses, to

server solutions that allow unlimited access via Web browsers. If paying per seat, its important to

understand the user mix. Licenses that dedicate one installation per seat can be more costly

compared to those allowing a given number of clients to be on-line at once.More critical than the

price tag alone is a projection of cost savings, ROI and growth catalyst. While archiving, many

companies have discovered they were archiving duplicate artwork purchased by different divisions of

the company, a practice which could be avoided through proper asset management.The time savings, as

outlined in part one, is an obvious ROI. In many businesses, especially media-intensive ones, an

investment in the optimal digital asset management solution can even kick profitability into high

gear and be critical to sustaining a competitive advantage. Besides your employees, your library of

product samples and references are one of your companys most valuable assets. Evaluating DAM

solutions that best suit your specific needs requires that you keep your primary goals in mind. No

one provider offers a solution ideal for every company, and it is entirely possible that no single

vendors solution will solve all of your needs.

Editors Note: This is Part Two in a two-part series written after the CAD Expo plus Show, held

recently in New York. Part One, The Art of Achieving, appeared in the October issue of ATI.

November 1999