ITMA 2003: Global Marketplace

ITMA 2003 set a positive tone among machinery manufacturers for the future of textiles.The

124,910 visitors in attendance during the course of the eight-day ITMA 2003 shared with exhibitors

an overall optimism about the event. Housed in 20 halls at the National Exhibition Centre (NEC),

Birmingham, England, and covering more than 120,000 square meters of exhibition space, the latest

in textile technology from every sector of the industry was on display for the global textile

community. Rodger Hartwig, vice president, Symtech Inc., Spartanburg a representative of many firms

taking part in the show stated: This ITMA has been an excellent show. It is unfortunate that every

US customer didnt have a representative here. There are many new ideas that could benefit their

companies. The US industry would benefit from the positive atmosphere at this ITMA. Textiles

definitely has a future.ITMA 2003 Organizing Committee Exhibition Director Maria Avery reported

that 50 percent of visitors came from Europe, and almost 25 percent came from Asia, Southeast Asia

and the Middle East. Sixty percent of all visitors were at the director level and above.Italy-based

Savio S.p.A.s sales during the show confirmed a diverse visitor geography. This ITMA was a real

ITMA, not a surrogate, said Daniele Pellissetti, order administrator director. The attendees were

very high-quality. We sold machines to Turkey, China, Brazil and India. Also, we saw visitors from

unexpected countries like Argentina, and have finalized orders. The quality of the visitors and

global nature of the show have made the introduction of the new Flexirotor an important launch.

Savios FlexirotorS 3000 was on display for the first time at the show.Other suppliers in the

spinning sector reported positive results, despite pre-show jitters caused by major suppliers in

the sector withdrawing from the show. Hideki Ichikawa, general manager, sales department, Murata

Machinery Ltd., Japan, said: We believe it was a very important decision to attend. Worldwide

serious customers [from] Turkey, Bangladesh, India and more serious clients with fruitful meetings.

New winding and Vortex systems were well received and sold with good results. Company Chairman

Junichi Murata, and President and CEO Daisuke Murata explained that with 22 years dedicated to

Murata Jet Spinning and nine years to Murata Vortex Spinning, the company continues to develop yarn

manufacturing systems having ever greater performance and flexibility. The yarn package also is of

great importance in Murata development. The company claims the package can be used directly by the

fabric manufacturer without requiring additional clearing and winding steps.Marco Volpi, sales

support, Marzoli S.p.A., Italy, was optimistic about the future. Marzoli is progressive and

thinking to the future, he said. The C601 card is the beginning of a new line of machines, bringing

a new element of quality inside and out with technical improvements, as well as aesthetic

design.Spinning suppliers were well represented at the show despite the absence of some notables

and presented a variety of technologies. Trutzschler GmbHandCo., Germany, made full use of the

opportunity to literally unveil the new TC03 card on the first day of the show.

Tubular Textile Machinery, Lexington, N.C., was one of the many exhibitors in the dyeing and

finishing sector. Dyeing and finishing exhibitors at ITMA occupied the largest area 33 percent of

total floor space.Weaving Draws AttentionThe weaving sector was the largest visitor draw to ITMA

2003, according to show organizers. West Point, Ga.-based West Point Foundry and Machine Co.

President Pate Huguley said: It would have been a mistake not to come to ITMA 2003. Even with major

exhibitors pulling out, weve been pleased with the number of decision makers here. Denim prep and

corduroy-cutting machinery have been strong, as well as other products. We came presold on the

equipment on display, but we are looking at new projects one to three months out. Scott Warren,

general sales manager, added: Weve seen customers from Pakistan, India, Turkey and more. ITMA has

enabled us to reconnect with customers in this region.Even with the presence of well-known US

textile manufacturers visiting the show floor, numbers and ability to invest given the recent state

of the industry was often the topic of discussion. When asked about US attendance,

Spartanburg-based Sultex (USA) Inc. President Fritz Legler said: We saw many companies

approximately 70 from North America. We sold machines, air-jet and rapier, in North America, mainly

serving industrial and technical applications. Sultexs display was dominated by the L9400 air-jet

weaving machine with power leno designed for technical uses and carpet backing.Sultex also reported

the sale of 412 latest-generation projectile weaving machines to Tessival S.p.A., Italy. All of the

machines will be equipped with four-color weft insertion; tappet motions and electronically

controlled dobbies will be used for shedding. Tessivals product range includes fine poplins through

dense tickings, as well as loomstate clothing fabric and heavy bull denim. The company stated 156

weaving machines will partly replace existing machines in the Fiorano facility, and 256 weaving

machines will be housed in a new facility in Italy. Italy-based Promatech Commercial Director Fabio

Mazzucchetti remarked on the optimism at the event: We feel a positive movement, much less negative

than we expected. Weve sold both air-jet and rapier installations in Taiwan, India and Brazil. This

show creates an optimistic, positive future for textiles. Weve sold more here than at the Paris

ITMA, and weve noticed a high quality of people, extremely well prepared. It is not just speed they

are researching the details.This show was much more active than we expected, remarked Francesco

Cecchinato, area sales manager, SMIT S.p.A., Italy. SMIT recently emerged as a stand-alone company,

spun off from Sulzer Textil following the ITEMA Groups acquisition of Sulzer. The G6300s

new-generation GS900 and JS900 air-jet, both coming next year, saw great interest, Cecchinato said.

The terry version of the G6300 impressed clients, as did the one equipped to produce airbag

fabrics. We expect that 200 machines have been sold at the show in the China, Korea, Taiwan and

Japan sector, and another 600 machines will be placed in the first quarter. Without final figures,

we expect sales around the world of 1,000 machines have been concluded at the show.In a non-weaving

development, Egon Wirth, Germany-based Lindauer Dornier GmbHs marketing communication manager,

pointed out a new, patented development a magnetic guide for Dorniers circular expander. Magnetic

bearings allow contact-free fabric guidance.Marco Giamminola, managing director of Giorgio

GiamminolaandC S.p.A., Italy, agreed with the overall impressions of ITMA. The people here came to

gather real information not for tourism, he said. As a spare parts supplier and used weaving

machine company, we met clients and made new alliances. We have broadened our range of parts and

introduced our website, which makes the sales process even stronger.According to Belgium-based

Picanol NVs latest information, the companys weaving machines received a very positive reception at

ITMA. In terms of both new leads and new contracts, the company realized better-than-expected

results.Picanol expects 2004 will be a transition year and foresees the first recovery in 2005. In

2005, the new Olympica product platform, which will be launched by the end of this year at

ShanghaiTex, will be fully in the market. This is part of our strategy to secure new customers by

means of new type machines in geographic markets and niche segments where we have not been active

thus far. Following an initial order of 41 TERRYplus terry weaving machines in August, the order

for an additional 30 terry weaving machines destined for Brazil illustrates that we are on the

right track with our geographic focus. The recent order for 78 of the Olympica weaving machines by

a new Chinese customer in turn proves that our approach to accessing the niche segments is bearing

fruit, stated Jan Coene, president and CEO. In addition, we note that [Global Textile Partner], in

spite of a slower-than-anticipated start-up, is picking up impetus very nicely and will reach

regular cruising speed by 2005. Among the most active areas, the weaving halls had huge displays

from all the notable companies. Upcoming Textile World features will include technical details of

these machinery developments.

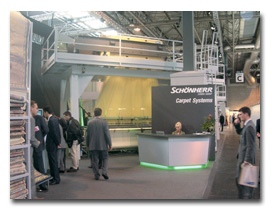

Schonherr Textilmaschinenbau GmbH, Germany, a member of the Stli Group, exhibited in the

weaving sector.Weaving sector visitors rose 4 percent over ITMA 99 attendance figures to comprise

18 percent of total visitors to the show.Beyond WeavingITMA 2003 offered much more than spinning

and weaving. Each sector of the industry was represented, with international companies vying for

the industrys attention. Some companies gained additional attention through the networking of

suppliers to the industry. John C. Blasman, CEO, Jomar Softcorp International Inc., Canada, stated

that ITMA gave us the opportunity to meet with traditional clients, as well as the textile

machinery manufacturers who are interested in implementation of our systems. Weve seen great

interest in on-line, Internet capabilities with interfaces to ERP, supply chain and outsourcing

solutions. Jomar has long been known for its textile manufacturing software and a number of

software solutions.According to the ITMA 2003 Organizing Committee, for the first time ever at

ITMA, there was a separate sector within the show for nonwovens, which incorporated all types of

machinery for web formation, bonding and finishing of nonwovens, and felting; and their

accessories. Sixty exhibitors showed their latest nonwovens technologies in a dedicated area of

11,000 square meters.The nonwovens area created quite a buzz at the show, with rumors flying that

major US placements had occurred. Given the activity on the show floor among venerable nonwovens

machinery firms and US clients, it would not be surprising, but at this writing, sales commitments

could not be confirmed.The knitting area of the show also held promise. With the separate

unaffiliated International Knitting Machinery Exhibition (IKME) held in Milan just prior to ITMA,

many knitting suppliers scrambled to ensure a presence at both shows (See the January 2004 issue of

TW for a review of IKME). Companies such as Groz-Beckert KG, Germany; Santoni S.p.A., Italy; Comez

S.p.A., Italy; and Kern-Liebers GmbH, Germany; pulled off a major presence at both venues.Digital

printing showed progress at the show. Wilmington, Del.-based DuPont Ink Jet Textiles Global Sales

and Service Manager Stephen J. Hurff noted: DuPont Artistri digital offerings in acid, reactives,

pigments and disperse have been really well received. At this global show, weve experienced strong

interest from Italy, Turkey, India, Pakistan and new interest from South America. DuPont sold the

pigment and disperse machines on display at the show, and its installed base will now exceed 20

units. The machines have attracted the attention of graphics and traditional textile

manufacturers.ITMA 2003 was also the first at which major dye and chemical suppliers held

significant space. BASF AG, Germany; CHT R. Beitlich GmbH, Germany; Clariant Ltd., Switzerland;

Cognis GmbHandCo. KG, Germany; DyStar, Germany; and other suppliers made presentations and promoted

their latest solutions many incorporating cross-technology developments with machinery suppliers,

such as DyStars involvement with Brazzoli S.p.A.s Innodye®/Innovat® system.Ciba Specialty

Chemicals, Switzerland, supported multiple chemical solutions, and in conjunction with Israel-based

Scitex Vision Ltd. and Reggiani Macchine S.p.A., Italy, presented the DReAM ink-jet printing

machine. Digital printing appears to be growing and continuing to meet the challenges of the analog

printing environment.The dyeing and finishing sectors were well represented by international

exhibitors. Jordi Argelich, textile dyeing machines sales and marketing manager, Argelich, Termes Y

Cia S.A., Spain, stated: We saw more people than we expected of the highest quality. We received

the opportunity to make offers and confirmed more sales than we expected. Our Rapidstretch machine

received the most interest. Turkey, Bangladesh, India and Pakistan were strong markets Asia is most

important. We see Brazil and Argentina coming on strong.An exhibit area that always seemed busy was

Biancalani S.p.A., Italy. Rossano Biancalani, general manager, confirmed that the sale of five

machines took place at ITMA, with new sales pending. Our customers are coming from all fields,

including knits and upholstery. We have had a good number of customers from the United States. Asia

and Turkey are also present. Interest is strong because our machines add value.Buddy Humphrey, vice

president, sales, Fort Lawn, S.C.-based Morrison Textile Machinery Co., stated: Overall, this has

been a very good show. Interest has been in the full range of products. Clients ranged from

Pakistan, India, Turkey and several from the US and China.Klaus A. Heinrichs, vice president,

marketing, A. Monforts Textilmaschinen GmbHandCo. KG, Germany, said: Without official figures, we

are very pleased with the overseas visitors Turkey, Pakistan, Egypt and Italy and the level of

quality. We count this show as a great success for our company. We were gratified with the

logistics of the show; however, signage was a problem. Against all odds, this was a good show.ITMA

is a magnet for visitors. Even with ShanghaiTex [coming in December], we had visitors from Asia,

Heinrichs said. I believe this to be the number-one country and show for textile machinery

manufacturers.Henrichs brought to light a complaint of many visitors and exhibitors: The locations

of the exhibitors were difficult to find, and the booth location numbers were difficult to

navigate. The impact was marginal on large exhibitors such as Monforts, with its massive signage

and display areas. However, small exhibitors found navigation to be problematic. Hall 16

exhibitors, located on their own in the middle of the NEC complex, also had concerns about the

level of traffic due to the out-of-the-way location.

Whether looking for large carpet weaving looms from NV Michel Van de Wiele (above left),

Belgium, or testing equipment from James H. HealandCo. Ltd. (above right), England, the audience at

ITMA 2003 was global. Fifteen percent of visitors came from the United Kingdom, 7.8 percent from

Turkey, 7.5 from Germany, 6.6 percent from Italy and 6 percent from Pakistan. The United States, in

tenth position, made up 2.8 percent of total visitor figures.Pace QuickensAs the major

international textile event drew to a close, two points were clear: The pace of technological

development in textile processing is as strong as ever, if not stronger; and domestic and

international suppliers to the textile industry continue to invest in development and are bringing

textile solutions to the table. Those innovations will lead to increased productivity; increased

flexibility of plant output; and improved performance, hand and finish of textile products. In

future issues of TW, a range of technology-oriented overviews will highlight these industry

developments.In speaking with major technology suppliers, TW learned that US textile manufacturers

are working hard to attend and participate in events like ITMA, but the going is rough, given the

domestic US manufacturing environment. The investments most commonplace when referenced in

interviews from the exhibit floor pointed to Turkey, India, Pakistan and Asia as hot markets for

technology. In an interesting aside, one US industry manufacturer commented that the competition

facing US manufacturers in textiles will soon hit machinery suppliers. With more than 700 textile

machinery manufacturers in China, only time will tell if the technology suppliers will also soon

feel the pinch in the global marketplace.

December 2003

Unidex Inc.

Unidex Inc.