W

ith temperatures in the single digits and snow on the way in New York City, buyers

shopping the fabric shows for their Spring/Summer 2005 apparel collections were warmed by the sunny

colors, bright conversational prints, diaphanous fabrics, sateens with subtle luster and romantic

embroideries. The six shows, which took place over a 10-day period, presented new colors, designs,

techniques and marketing tools – all crafted to bring a fresh look to a new season.

Direction and Printsource New York were the first to herald Spring 2005 with showcases for

surface design. Both shows have expanded in the last several years. According to Lisa Mainardi,

Direction producer, the number of exhibitors has increased by 25 percent and attendance has tripled

in the past year and a half. At the most recent Direction show, 110 booths representing 120

companies presented prints, embroideries, beading and other application treatments, designs for

knitted fabrics, yarns, color resources, CAD equipment and trend services. Pantone Inc., Scotdic

Colours Ltd., Yarn Mavens Inc., Pointcarre USA and Meadowbrook Inventions Inc. were new exhibitors

at the show.

Direction surface design trend display

Direction surface design trend display

At Printsource New York, Massimo Iacoboni, show director, said there is a waiting list for

new exhibitors, and attendance has been steadily going up. “Along with major print converters,

apparel manufacturers and retailers who come to our show, we are seeing more people from the home

furnishings trade, and hosiery and accessories companies,” he said.

Five days later, the city hosted European PreView, the Turkish Fashion Fabric Exhibition

(TFFE), and Innovation Asia, as well as the Italian Trade Commission, which showed trends developed

for the Moda In show in Milan. Although the focus of all the shows was on Spring/Summer 2005, a lot

of mills had their Fall 2004 collections on hand for late selling.

Attendance figures for European PreView, Direction and Printsource New York came in at more

than 2,500 at each event. Daniel Faure, chairman, European PreView, said the market is changing

rapidly. “Our database in France is constantly updating,” he said. “In order to be of service to

our exhibitors, we must bring the right level of buyers to this show.”

Of the 123 exhibitors at European PreView, 43 came from Italy, and an equal number from

France. Others are based in Portugal, Spain, Austria, Germany, Switzerland, Belgium, England,

Scotland and Ireland.

A large floral print from Seterie Argenti S.p.A.

A large floral print from Seterie Argenti S.p.A.

Color Is In Demand

Buyers at all of the shows were enthusiastic about what they saw. At European PreView, Jerry

Dellova, design director for Barry Bricken, Owings Mills, Md., was shopping for fabrics from

the Spain-based mill Pasarela S.L. “I am so glad to see so much color, and in woven fabrics,”

Dellova said. “Our customers are clamoring for color. I used to be the king of beige, stone and

putty. After the reaction we had to a hot pink jacket, I am shopping for more color.”

Pasarela showed vibrant colors, bright prints and textured tweed suitings. The line is woven

using polyester and blends with viscose, cotton and Lycra®. One of its best sellers is stretch

cotton sateen. Conversational prints and bold geometrics are popular as well.

Camille Block, designer for Q-T Foundations Co. Inc., Norwood, N.J., a company that makes

private-label intimate apparel, said: “Our customers love color. And I am seeing more prints than

ever before that look right for the missy and full-figured woman.” She liked stretch satin

conversational prints and jacquards at La Industrial Sedera S.A., Spain.

Among the fabrics mentioned by Angelo Uslenghi in his Spring/Summer 2005 forecast developed

for Moda In are satins, sateens, crepes, piqués, seersuckers, crepons, voiles, georgettes,

honeycombs, hopsacks, slubbed linens, jacquards and mesh.

Fabrics featuring Lurex® from Marioboselli Jersey S.p.A.

Fabrics featuring Lurex® from Marioboselli Jersey S.p.A.

Linens

With stretch and care-free finishing treatments, linen is increasingly popular. At European

PreView, Northern Ireland-based Ulster Weavers showed traditional Irish linen that was updated in

style and technology. Twills with lustered finishes contain Lycra, rugged basket weaves are dyed in

jungle colors, and linen bouquets are reminiscent of Chanel.

Scotland-based weaver Robert Noble showed linen blended with silk and cotton. Sheer, open

gauze weaves have been adapted from its curtain line. Tweeds in classic patterns have a dry hand.

Isoule Textile, France, has multi-colored yarn-dyed tweeds with lustered yarns running

through them, for a look that is young Chanel.

Italy-based Solbiati has two-ply crepes, chintz linen that is soft and drapable, thick open

weaves, rustic hopsacking and tie-dye effects.

Bright, fresh colors in romantic pastel shades or sunny brights from Libeco-Lagae, Belgium,

turned up in a variety of space-dyed stripes. They are woven with ultra-fine yarns; the fabrics

have a crisp touch and slightly crinkled surface. Other fabrics are woven in a blend of

linen/stainless steel. The metal gives luster and memory to the fabrics. There are Panama weaves

with tone-on-tone shadings, crepe weaves and blends with Lycra.

At TFFE, Bossa was selling linen/cotton blends to the menswear market. There was high

interest in summer tweeds for jackets and trousers in blends of linen/viscose/polyester. Other

fabrics in this line include dobbies woven with fancy yarns and classic stripes.

BTD, also at TFFE, had linen/viscose blends with a soft touch. Kenneth Master of New York

City-based Club Monaco, said, “Here I can find novelty at our price points.” He was looking at

textured stripes woven with fine yarns, cotton/Lycra sateens and casual fabrics with silicone

finishes that give them a cool touch.

G-Vision International, an exhibitor at Innovation Asia – facilitated by England-based Tencel

Ltd. – had linen blends with metallic stripes. The Korea-based knitter has a variety of fabrics

ranging from silky matte jersey to jacquards, mesh and crochet looks. Also at the show, Japan-based

Toyoshima had Tencel®/linen blends that have a lot of stretch, and are machine-washable and

-dryable.

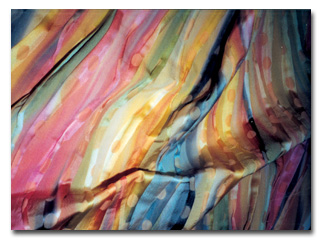

A pastel rainbow-striped sheer silk fabric from Weisbrod Zürrer AG

A pastel rainbow-striped sheer silk fabric from Weisbrod Zürrer AG

Knits

Crepe-stitch knits are making a comeback. At Italy-based Marioboselli Jersey S.p.A., a

European PreView exhibitor, they are knitted in silk/viscose and have a soft hand. After all of the

shine, buyers are starting to look for soft, matte crepes. Jacquards with splashes of Lurex® and

silk/copper stripes and squares also were popular. And, with buyers looking for more individuality,

Marioboselli is selling fabrics prepared for printing, and also will print a customer’s exclusive

designs.

Open crochet patterns in nylon and nylon/Lycra blends, engineered stripes with coordinating

jacquard patterns and yarn dyes were the early best sellers at France-based Billon Frères, another

European PreView exhibitor.

Tencel knits at Innovation Asia tended to have a soft hand and natural stretch. Fountain Set

(Holdings) Ltd., Hong Kong, Dainong Corp., Korea, and Willgold Industrial Co. Ltd., Taiwan, showed

them in blends with cotton, nylon or polyester.

At TFFE, Gulle Tekstil San A.S. sold knitted fabrics to intimate apparel and activewear

markets in blends of cotton or viscose with Lycra. A lot contain metallic yarns as well.

Tom Cody Design exhibited romantic designs at Printsource New York.

Tom Cody Design exhibited romantic designs at Printsource New York.

Prints

If buyer reactions at these shows are a criterion, Spring 2005 will see a lot of printed

fabrics. Studios showing at Direction and Printsource New York all reported that scenic

conversationals are the number-one seller. At The Colorfield Design Studio, retro scribbles,

tropicals and small-scale geometrics also were popular. Colors and combinations of bright with

neutral, coral and green shades were cited. The company also offered ethnic figuratives, romantic

florals, softer graphic and geometric designs and retro patterns reminiscent of the 1920s.

Tropicals, geometrics and skin patterns were top sellers at Marilyn Kern Textile Designs

Inc., New York City. Amanda Kelly Design Studio, England, described its flower prints as “1930s tea

dress florals.” Textured looks and conversationals also sold well. Bold, high-energy stripes,

large-scale geometrics, cowgirl conversationals and watercolor flowers were popular themes at

Westcott Design Ltd., London.

Tom Cody Design, New York City, reported romantic and sexy designs sold well. A lot of Cody’s

prints have a feeling of movement, and many are going on tie-dyed backgrounds. At Splash Ltd., New

York City, retro patterns are updated using vivid colors. There are butterflies in this line as

well, and a lot of hand-crafted looks.

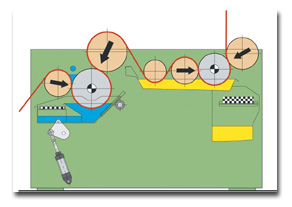

Last August, Direction started selling print designs from its website,

www.directionmarketplace.com. “It is completely

safe and private,” said Mainardi. Vendors can control who looks at their lines, and there is no way

a pattern can be copied or downloaded without the consent of the seller.

European Preview attracted more than 2,500 visitors.

European Preview attracted more than 2,500 visitors.

Prints At European PreView

A lot of the same ideas turned up at European PreView. Italy-based Segalini Manifatture

S.p.A., Italy, showed African ethnic and jungle designs in earthy colors, graphic florals in warm

bright shades, small sweet flowers in baby pastels, and stripes and checks that have a feeling of

movement. Silk crepon, chiffon, georgette and satin are some of the base print cloths. Others are

cotton canvas and drill.

Ronald Sheridan, agent for France-based Chaine et Trame S.A., said the focus of the company’s

line is young and trendy. Conversational and figurative prints are going on both top- and

bottomweight fabrics. Stretch cotton sateen, stretch poplin, rayon/spandex jersey and polyester

mesh are some of the most popular fabrics. Tropicals and sparkle prints are other popular designs.

Black-and-white turns up with touches of red.

Italy-based Miroglio S.p.A. called its collection Pre-Spring. Piqué, mesh and cotton stretch

are some of the base cloths. There are flocked butterflies, mosaic designs, flat florals and

engineered patterns. One floral print is worked with stripes so a shirt can be made with stripes on

the sleeves and flowers on the front and back.

At TFFE, conversational prints shown by Confetti Textile took on the form of faces, shoes or

bags with a 1950s quality to them. There are dots of different sizes and placements, graffiti, and

designs reminiscent of Pucci. Saydam Tekstil showed prints on satin and taffeta for eveningwear;

the casual line turned up on linen, cotton and blends. Some designs are printed on linen/Lenpur®.

Shantung, sheers and metallic glitter are in this line.

Silk Sector

Tina Wilson, designer for Donna Karan Intimates, was looking for soft, cozy robe fabrics with

a good hand. She found microfiber stretch terry and embroideries at Atelier Scarabee, France. She

also mentioned prints at Italy-based Clerici Tessuto & C. S.p.A. Brightly colored jungle

prints, large engineered floral prints with striped borders, silk/cotton soft satins and matelassés

are some of the highlights of this line.

Switzerland-based Weisbrod-Zürrer AG said Summer 2005 will be a silk season. The company’s

early line includes fringed jacquards with a retro look, and pastel rainbow-striped sheers in a

blend of silk/cotton/linen available with random tucking. Black-and-white tweeds have a dimensional

look to them.

At France-based Bianchini Férier, there are flocks and printed georgette of silk/viscose.

Big, flat florals or butterflies are printed on faille. Shiny lacquer prints on crisp, transparent

fabrics also are available for Spring.

Leslie Potter, design director, Susan Bristol Inc., Boston, looked at prints at Seterie

Argenti S.p.A., Italy. She liked overprinting and flocking on textured fabrics, large florals and

new geometrics. Argenti showed cotton voile and sateen, stretch jacquards, jacquards with

coordinating patterns, washable viscose georgette and silk chiffon.

Mantero Seta S.p.A., Italy, showed five groups. Fabrics in the Summer Frost category include

florals and geometrics in fluorescent colors with gray. Some have a shiny, frosted finish. Essence

of Nature colors include dark and acid greens and blues. Prints are large, blurred abstracts and

jungle looks. There are feminine florals in shades of yellow and melon in a group called Blush

Garden. Cirque du Soleil colors are strong. There are mixed dot patterns, multicolored zig-zags and

combinations of rectangles. Batiks and paisleys in shades of pink turn up in Nativa, a group

reminiscent of India.

March 2004

The

The