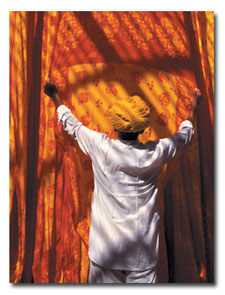

L

everaging India’s growing strength in the global textile industry, TEXMAC India 2007

International Textile Machinery Exhibition will premiere Jan. 17-20, 2007, at the Pragati Maidan

Exhibition Centre in the country’s capital of New Delhi. More than 15,000 registered visitors

expected at the show’s first edition will view the latest machinery, products and services from a

wide range of exhibitors – situated among 15,000 square meters of hall space.

According to the show’s organizers – Internationaler Messe- und Ausstellungsdienst GmbH

(IMAG), Munich, and Fair Design India Pvt. Ltd. (FDI), New Delhi – TEXMAC capitalizes on the high

manufacturing capabilities and growth potential of India’s textile industry. Accounting for 3

percent of the country’s gross domestic product and 24 percent of all Indian exports, and as the

second-largest employer behind the agriculture sector, the textile and apparel industry is a

significant contributor to India’s economy. Factors that may further strengthen the industry

include investments in new technologies and planned modernization of certain subsectors, the

removal of European Union (EU) and US import quotas, the reduction of import duties for textile

machinery, and economic reforms – such as the 10th Five Year Plan of India (2002-07) and the

privatization of government-owned enterprises. India’s textile production has increased by 33

percent since 2003, and total production value by 2010 is projected to be US$85 billion, the

organizers report.

IMAG and FDI have touted the exhibition as a centralized marketplace for textile machinery.

Products on display will include: washing, bleaching, dyeing, printing, and finishing machinery and

accessories; spinning, weaving, knitting, nonwovens, and make-up machinery and accessories; and

other machinery and accessories. Vendors of dyestuffs and chemicals, testing and recycling

equipment, transport and handling machinery, software, and other goods and services also will be

present. Germany, Italy, Great Britain, Turkey, China and Taiwan, Korea, Belgium and the United

States are among the countries and locales that will take part in the exhibition’s national

pavilions.

Worldwide Support

Support from the New Delhi-based Confederation of Indian Textile Industry (CITI) and its 16

affiliated member associations, as well as from the Milan-based Association of Italian Textile

Machinery Manufacturers, has contributed to the organizers’ outreach efforts to textile

representatives in India and in neighboring countries. In addition, the India Trade Promotion

Organisation has approved the show; and the British Textile Machinery Association; Indo-German

Chamber of Commerce and Industry, New Delhi; Swissmem Textile Machinery Division, Switzerland; and

Textile Machinery Manufacturers and Accessories Manufacturers Association, Turkey, have consulted

with organizers.

IMAG and FDI have promoted the event to potential attendees from India, Sri Lanka,

Bangladesh and Pakistan through press conferences, media partners including trade journals and the

daily press, direct mailings, and travel packages tailored to visitors from significant textile

manufacturing hubs in India and abroad. Major companies in the textile industry have included the

show in their exhibition programs, the organizers note. Among the targeted visitor groups are

representatives of textile, spinning, weaving, knitting and dyeing mills; clothing machinery

manufacturers, wholesalers and importers; wholesalers, distributors and retail associations; the

textile machinery industry; trades and crafts; and services, research and education. As of Textile

World’s press time, 206 companies from around the world had expressed interest in exhibiting at

TEXMAC India 2007.

According to organizers, the show will be scheduled biennially and the exhibition space of

future editions may grow.

ATEXCON

CITI’s Asian Textile Conference (ATEXCON) will occur concurrently with TEXMAC on January 18

and 19 at the Hotel InterContinental, New Delhi. The conference’s second edition will build on the

success of the December 2005 event. Inaugural conference attendees – including suppliers and buyers

from India, Bangladesh, China and other Asian countries; European machinery manufacturers and

consultants; and industry representatives from the United States and Europe – gathered to trade

information about trends, prospects and the future of the Asian textile and apparel industry. Fiber

and yarn, technical textiles, technology developments, home textiles, and garments and

international trade were the subjects of business sessions addressing the premiere edition’s theme

“Emerging Trends in Asian Textiles.”

The theme of ATEXCON 2007 will be “Competing Through Productivity Gains.” On the first day,

as part of that theme, attendees will hear speaker presentations and examine case studies about

managing productivity in the textile industry, and productivity and cost competitiveness in the

apparel sector; and will partake in discussions about those topics. A second business session will

concentrate on technology developments, including smart fibers, the future of spinning capacities,

technical textiles, weaving and processing innovations, and smart garments. Asian textile and

apparel corporations also will present their findings and will lead discussions about growth

through value addition during the third session.

On the second day of the conference, capacity building trends and requirements will be the

focus of the fourth session. Attendees will discuss and listen to presentations about investment

trends and financing requirements. The textile and apparel industries in Asia, the United States

and EU; and the trends and prospects of intra-Asian trade flows will be among the topics examined

during the final business session, focusing on international trade.

For more information about TEXMAC, contact Catherine Schultheiss (international)

49-89-949-22-124; schultheiss@imag.de; or L. Shyamsundar (In India) 91-9811355527; fdi@vsnl.net;

www.texmacfairs.com. For more information about ATEXCON,

contact the Confederation of Indian Textile Industry 91-11-23325012; mail@citiindia.com;

www.atexcon.com.

November/December 2006