Business continues to be strong for spinners in mid-September. Ring-spun yarns are in high demand,

as are a variety of polyester and blended yarns. Spinners and yarn brokers also report increased

sales of open-end yarns.

The recent surge in sales accounts for the most sustained period of brisk business for many

spinners since mid-2011, when a frenzied 18-month upcycle came to an end.

“Business has been good for some time, now,” said one spinner. “We started getting more

inquiries and orders back in July, and it has been pretty constant since then.”

A prominent yarn broker agreed: “My business has been strong since at least August. It’s

been a combination of factors, I believe. Retailers have thin stocks and are beginning to

replenish. The price of imported yarn has been increasing and the availability has been

diminishing, which brings more business back to this hemisphere.”

The outlook for the remainder of the year remains promising as well. “It looks like the

fourth quarter is going to be relatively strong, at least in comparison to last year,” said one

spinner. “I believe there may be a slight slowdown around the holidays, but I think it will pick up

again at the beginning of the new year. Hopefully, we are in for a pretty good run.”

Some spinners report that, while they have a steady pipeline of business, the size of the

orders remains relatively small. “We do a lot of short runs, a lot of changing out,” said one

spinner. “Everybody wants something just a little different, and, as always, they want it

yesterday. It puts a lot of pressure on the business to deliver.”

With the improved business conditions, order delivery times for many customers, as expected,

are increasing. “A few months ago, a two-week turnaround was about the norm, and you could get it

even faster in some instances,” said one buyer/broker. “Now, you are looking at six weeks or more

in some cases.”

Pricing Pressures Escalate

Despite the increase in both inquiries and orders, spinners are still dealing with

considerable price pressures. “We are fighting a constant battle to maintain margins,” said one

spinner with operations in both the United States and Central America. “Our customers want to place

the business. But they want it at a price that is just not sustainable for us right now. We have to

negotiate hard for every penny on the pound.”

The pricing pressure is particularly acute for smaller spinners, according to industry

sources and observers. “Large spinners have programs in place where they can accommodate business

at a price significantly less than what the rest of the industry can afford,” said one industry

insider. “A customer might call up a large spinner and say, ‘What’s your price on 30/1 combed

cotton?’ And the answer might be, ‘We are selling it for $2.10.’ Then, the customer says, ‘I want

5,000 pounds.’ And then the large spinner says, ‘I can’t sell you 5,000 pounds. I have 1,000

pounds, but that’s it. The rest of it is committed, unless you want to wait awhile.’ So, the

customer then calls a smaller spinner and asks the same questions. But the smaller spinner’s price

is $2.75. So, the customer tells the smaller spinner the price is too high and won’t place the

order. It’s a conundrum. At some point somewhere, the cycle is going to have to break. Most of the

industry can’t afford to sell yarn at those prices.”

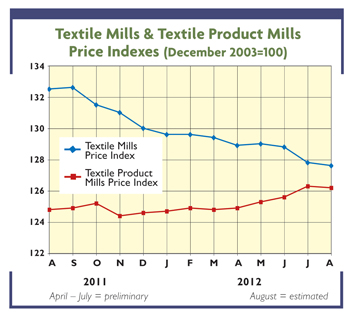

Price Of Cotton Stabilizing

For the week ending September 14, the price for the base quality of cotton in the seven

designated markets measured by the U.S. Department of Agriculture averaged 70.19 cents per pound,

down from 71.59 cents per pound the previous week, but up from the 67.98 cents per pound reported

August 17. The price has been hovering in the 70-cents-per-pound range for the past several months,

after falling from record highs in early 2011. “Certainly, the fact that prices have stabilized

somewhat is a contributor to the increases in business most of us have seen,” said one spinner.

“Customers are beginning to realize that they can place orders and not be caught short. More than

anything, I think, our business just needs some stability over an extended period.”

September 2012