The Cranbrook Educational Community Board of Trustees, Bloomfield Hills, Mich., has named Christopher Scoates director, Cranbrook Academy of Art and Art Museum.

Innovatext, Hungary, has named Lívia Kokas Palicska, Ph.D., director.

New York City-based Simparel Inc. has named Larry Mora senior project manager.

Brand & Oppenheimer Co. Inc., Red Bank, N.J., has named Lizz Gillcrist business development and marketing manager.

August 2014

People

SGS Inaugurates New Textile Testing Laboratory In Phnom Penh, Cambodia

GENEVA — August 19, 2014 — The newly-inaugurated laboratory is equipped with the-state-of-the-art facilities to provide physical and restricted substances testing for the entire range of apparel and textile products and restricted substances testing for footwear products. The presence of SGS here will contribute to and strengthen the local apparel industry’s ability to attain a Global standard and acceptability.

Textile and Garment Industry in Cambodia

Cambodia remains the hub of ready-made garment exports to European and USA markets. This clearly demonstrates the increasing demand for consumer product testing services in the region. Product safety, quality and compliance requirements of REACH and CPSIA regulations have increased the need for chemical test parameters in the textile supply chain. The SGS new state-of-the-art facility is fully equipped to address these restricted substance requirements as well as sustainability management in the textile and apparel industry.

Improved Textile Testing Capabilities

The new capacity and testing capabilities of the SGS Cambodia laboratory serve the country’s ever expanding textile industry by providing valuable and rapid testing services to local textile and garment manufacturers needing to comply with international regulations and requirements. In addition to testing, quality inspection, compliance audits, factory assessment and loading supervision make SGS Cambodia a one-stop service provider for the country’s textile industry.

Textile Testing Laboratory – Inauguration Ceremony

The inauguration ceremony, attended by over 100 participants, was held on 8th August 2014 with a ribbon cutting ceremony and laboratory tour. Management representatives from SGS Group and honorable guests such as H.E. Christoph Burgener, the Swiss Ambassador to Cambodia, Myanmar and Lao, H.E. Touchayoot Pakdi, the Thai Ambassador to Cambodia, Mr. By Pitou , the Deputy General Director of Ministry of Industrial and Handicraft, and Mr. Oknha Van Sou Ieng, the Chairman of Garment Manufacturers Association of Cambodia (GMAC) attended the inauguration ceremony.

Posted August 19, 2014

Source: SGS Consumer Testing Services

Business & Financial: Fiber Costs: No Sweat

By Robert S. Reichard, Economics Editor

Both cotton and manmade fiber quotes continue to resist upward cost pressure, and this could be one of the key reasons why domestic textile and apparel industry earnings are being maintained and in some cases are actually edging higher. Looking at the cotton situation first: The U.S. Department of Agriculture’s production estimates for the 2014-15 marketing year puts global output at more than 116 million bales. That’s actually a bit higher than projected a few months ago. Mill usage over this period, on the other hand, is expected to fall short of this output estimate by some 5 million bales. Result: Year-ending stocks for the new marketing year are heading for their fourth consecutive year of advance. Viewed from another perspective, the global stock/usage ratio currently is targeted to top 91 percent. That’s more than double the extremely low ratio prevailing during the 2010-11 marketing year, when prices for the fiber skyrocketed — rising to well over $2 per pound. Zero in on U.S. numbers, and this year’s anticipated stock/usage ratio should also rise — again, more than doubling the four-year earlier level. This kind of inventory buildup, plus the fact that China now holds huge excess supplies, would seem to suggest that prices likely will remain fairly shaky. Indeed, they’ve already dropped significantly over the past few months, with some further modest erosion possible through year-end and into 2015.

A Look At Man-mades

The market outlook isn’t all that different when it comes to key man-made fibers. Again, it’s a scenario of more than adequate capacity with little or no near-term price firming anticipated. A closer look at polyester, which by far accounts for the largest share by far of the man-made market, pretty much tells the story. At last report, global production for this synthetic textile far exceeded the amount currently being consumed. Result: The combined polyester filament and staple utilization rate at last report was put only in the low 70- to 72-percent range. More importantly, this measure of market strength is not expected to change by much over the next two years as new capacity coming on-stream limits any significant improvement in operating rates. Best estimate for 2016: only a small polyester capacity utilization creep up to about 72 to 74 percent. And similar supply-demand imbalances are apparent when looking at most other man-made fibers. Given this scenario, Textile World editors see pretty much smooth sailing when it comes to near-term manmade fiber costs, not only for polyester, but also for other major constructions like acrylics, nylon and rayon. It also might be pointed out that there is still another price-rise inhibitor operating, namely the fact that man-made fiber feedstock costs — mainly petrochemicals — also are expected to hold fairly steady. To sum up: The near stability of man-made tags that has prevailed for more than 30 years now —they’ve risen less than 1 percent annually over this period — is likely to continue. As such, TW’s beginning-of-year forecast calling for only fractional increases in these costs can now be extended out to 2015 and perhaps even into 2016.

The Industry Impact

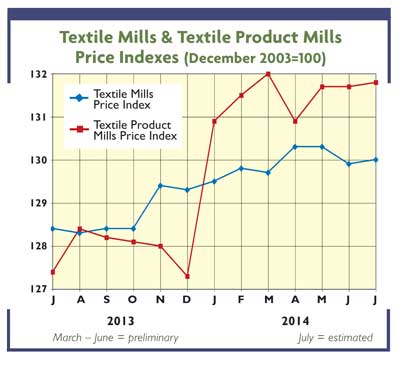

As noted above, these fiber cost trends are having significant positive repercussions on domestic industry health. And with good reason — namely because fiber procurement makes up a huge part of the average textile mill and apparel manufacturer sales dollar. This year, TW editors figure that fiber costs for mills making basic fabrics will account for about 51 percent of each dollar of product shipped. To be sure, that’s still a hefty chunk. But it’s a lot less than the huge near-70-percent-share noted in 2011, when cotton costs went through the roof. Similar declines in material costs per sale dollar are also noted for more highly fabricated textile mill products like carpets and home furnishings, with this year’s estimated material bite expected to run well under the 65-percent peak level recorded a few years back. Nor are things all that different in the apparel sector, where the 45 percent currently being earmarked for material needs remains well under the 3-year-earlier 62 percent reading. The implications of all this are pretty clear: Not only have these declines in the textile and apparel industries’ major cost outlay helped to holster profits and margins (see “Business & Financial,” TW, July/August 2014), but they have also helped keep textile and apparel prices at relatively unchanged levels — levels that remain extremely attractive to today’s cost-conscious consumers.

August 2014

The Rupp Report: A Lot Of Question Marks: Is India Isolating Itself?

Instead of continuing with the reports about physiological apparel, the Rupp Report is forced to take a look at India again: Some weeks ago, the Rupp Report asked: “What’s wrong with India? With millions of cheap workers and a huge domestic market, the country should be as successful as China, but it is not. The industry is underdeveloped and unproductive, and it contributes only some 16 percent to the gross domestic product (GDP). Responsible for this misery are the excessive bureaucracy, endemic corruption, poor infrastructure, permanent energy shortages, excessive taxes as well as outdated property rights and restrictive labor laws.” (See “The Rupp Report: Will India Recover Now?” TextileWorld.com, May 20, 2014.)

And now, there is the next act in a somewhat tragic drama, which might bring the second-largest population in the world into even deeper trouble and isolation.

India In Isolation?

For years, trade facilitations and standardizations of processes in the customs authorities have been central concerns of the World Trade Organization’s (WTO’s) somewhat dormant Doha Round of trade negotiations. At WTO’s Ninth Ministerial Conference in Bali, Indonesia last December, the unanimous adoption of the so-called Bali Package was celebrated as an historical breakthrough in the multilateral way and as an instrument to stimulate world trade.

And now, the Doha Round has suffered a severe blow. The first global agreement on trade facilitations in the WTO’s 20-year history has failed owing to the resistance of India and a handful of developing countries. In a night meeting of the representatives of the 160 WTO members in Geneva on July 31, WTO Director General Roberto Azevêdo reported that finalization of the agreement on global trade facilitations in customs matters had failed and could not be signed. It is a paradox: Experts have calculated that just the implementation of this agreement would create 21 million jobs around the globe and would boost the production of goods.

The United States’ WTO Ambassador Michael Punke was sad and disappointed after the short session — which did not include any discussion by the 160 WTO members — that a small number of countries were unwilling to meet obligations that they had agreed to during the Ministerial Conference in Bali.

Stubborn Indians?

In recent weeks, seconded by some developing countries, India has shown some signs of backing out of the agreement. The new nationalist government in Delhi doesn’t feel a responsibility to fulfill the obligations of the previous government. India is willing to sign the protocol to the agreement of Bali only if a solid waiver for India, supported in the basic rules of the WTO for the subsidy of staple food, is connected. Of course, this request was rejected by the majority of WTO members.

According to the WTO, it is mainly the developing and emerging countries that would benefit from the reforms in the Bali Package. However, a small group of malcontents, led by the new Indian government, took the opportunity to play trade liberalization against food security, and, once more, to paralyze the WTO. In short, the group not only killed the agreement on trade facilitations, which aims to simplify and harmonize the intricate, corruption-prone customs in industrialized and developing countries. Now the reputational damage to the WTO as the global supporter and referee of the trading system is very great.

At the Ministerial Conference in Bali last December, the participants managed to agree on a minimal program to wake up the Doha Round from its agony. In Bali, the Indian Minister of Commerce played all cards to expand the subsidization of Indian agriculture under the disguise of protecting the food supply chain. Now, an exception that was granted until 2017 should soon be replaced by a permanent regulation. If the new regulation were not to be concluded soon, Delhi was ready to collapse the agreement; and that’s what has happened now.

With this procedure, the Indian government is undermining its own credibility as a negotiating partner. Ultimately, former Indian Trade Minister Anand Sharma gave his blessings in Bali for the agreement on trade facilitations. Now, India is isolating itself within the WTO.

Meaningless WTO?

In contrast, according to conjectures by diplomats in Geneva, the WTO has now the risk of ending up in a dead-end street again and slipping into irrelevance if it should continue to prove its incapability to stimulate world trade through agreements for reduction of customs barriers and other impediments to the exchange of goods.

However, the major economies would not suffer, Azevêdo said. They have other options to push their trade relations. Victims of the final failure to reach a global agreement would primarily be developing countries.

The open and unanswered questions around the Bali Package are detracting from the real goal of the meeting of trade ministers: It was up to the member states to identify which concrete, unilateral measures they would contribute to the growth target that the G-20 finance ministers set last February. These measures stipulate that the collective GDP would be 2 percent higher than the forecasted growth.

And Now?

Many voices now predict the end of the multilateral treaty system in world trade. As for areas such as the climate and disarmament issues, there is no common mutual understanding. While the WTO has paralyzed itself in recent years, bilateral and regional trade agreements have filled the vacuum many times. There are also so-called multilateral agreements, where like-minded people grant preferences and get rid of mere copycats. With their blackmail, the Indians have rendered a big disservice to multilateralism.

Trade facilitation and standardization of customs procedures are one thing. The rightly feared sellout of a country’s food security, at first glance, is actually something else. At second glance, however, it is not. Between rich and poor countries, trade facilitations can always cause a dangerous tendency for one country to sell out its food security at the expense of poor countries. For the government of India, and particularly the billions of Indians, food security is of vital importance. One has to wonder whether it would be better to develop more sensitivity toward the existential needs of poor countries, instead of rich WTO countries deploring the pigheaded attitude of India.

And The Textile Industry?

Perhaps no other industry is so dependent on easier terms between countries as is the textile industry. It is to be hoped that the outcome of this Doha Round will not trigger bigger problems for the global movement of goods in the textile sector. It seems that precautionary measures should not be wrong.

The earlier Rupp Report about India asked the question, “Will India now recover?” For the moment, it seems rather not.

August 12, 2014

TENCEL® Jumbo Plant Comes On-Line

Lenzing Group, Austria, has begun production at its TENCEL® jumbo manufacturing facility in Lenzing, Austria. The 150 million-euro facility, the largest worldwide, is in the process of ramping up production, which is proceeding according to schedule and is expected to be completed within the originally planned timeframe of 24 months.

“We are more than satisfied with the progression of the startup curve,” said Peter Untersperger, CEO, Lenzing Group.

“We are optimistic that we will be able to achieve the planned production target of 30,000 tons by the end of 2014,” said Lenzing COO Friedrich Weninger. “This new TENCEL® facility is decisive to ensure the long-term viability of fiber production at the Lenzing site and the basis for future investments in all markets.”

The production line at the new facility, which employs 140 workers, has an annual nominal production capacity of 67,000 tons and enables Lenzing to raise total annual Tencel production capacity from 155,000 tons to some 220,000 tons. The company reports that the startup of the facility provides expansion opportunities for its customers in the textile and nonwovens segments alike, in addition to enabling development of new applications including technical applications.

August 12, 2014

Tex Tech Acquires Universal Carbon Fibres

Engineered high-performance materials manufacturer Tex Tech Industries, Portland, Maine, has acquired United Kingdom-based Universal Carbon Fibres Ltd. (UCF), a manufacturer of high-performance yarns and fabrics mainly using carbon-based fibers. Details of the transaction were not disclosed.

UCF products are targeted for use in technical and extreme environments. Its specialties include new applications for automotive fuel cells and friction materials, fire blocking for aerospace and transportation markets, and water-blocking technology for communication and power cables. The company also produces Panotex® inherently fire-resistant fabrics for personal protective apparel applications.

Tex Tech serves the aerospace, defense, industrial, law enforcement and sporting goods markets including companies such as Airbus, Boeing, Gulfstream, the National Aeronautics and Space Administration (NASA), BAE systems, Penn and Wilson. Its Core Matrix Technology™ protective material is used in advanced ballistic vests for military and law enforcement personnel. Other products include fire-retardant and thermal acoustic insulation used in commercial aerospace applications, and tennis felt.

“UCF’s strong relationships with its customers and fiber manufacturers, as well as its robust manufacturing capabilities in the United Kingdom, will significantly strengthen Tex Tech’s international presence,” said Ciaran Lynch, CEO, Tex Tech.

“UCF and our customers will greatly benefit from Tex Tech’s global distributioon platform and manufacturing proficiencies, which will shorten our product development timelines,” said Bill Capstick, managing director, UCF.

UCF is now a wholly owned subsidiary of Tex Tech, joining CarbonX® thermal fabric solutions developer Chapman Innovations, Salt Lake City, under the Tex Tech umbrella. UCF management, staff, location and operations will continue as before.

August 12, 2014

Nordson Introduces TruFlow™ Single Module Applicators

Duluth, Ga.-based Nordson Corp. has introduced TruFlow™ single-module applicators for optimized adhesive use and improved material delivery. The applicator features passively driven gears to deliver flow-metered hot melt material to the application point with variation management capability. According to the company, this capability enables reduced waste, improved product quality and enhanced production efficiency. Nordson reports variation management is especially useful for producers of nonwoven disposable hygiene products for which the manufacturing process has rapidly changing flow requirements.

TruFlow single-module applicators have a compact profile and require fewer cables and connections than conventional applicators for simple integration into a high-speed production line. The applicators also are compatible with Nordson’s Universal™ nozzles such as the Allegro® for elastic attachment.

August 12, 2014

Miller Weldmaster Acquires Triad, Spec, And Hot Air Products From Sinclair Equipment Company

NAVARRE, Ohio — August 8, 2014 — Miller Weldmaster, the leading manufacturer of heat seaming solutions for the industrial fabrics industry, has announced an expansion of its business with the acquisition of the Triad Wedge Welder, Spec Wedge Welder, and Roof Welding Tool product line from Sinclair Equipment Company. For over 28 years, the Sinclair Equipment Company has been a world leader in manufacturing portable, versatile equipment for the industrial textile and roofing industry.

The acquisition provides Miller Weldmaster the ability to service a greater range of equipment to fabricators within the industrial fabrics market as well as expand into new markets. Further, the establishment of a West Coast office and team in Diamond Springs, California provides greater accessibility to serve our existing and new customers in the western United States and Canada.

Adding to our Extreme Seam welding product line as well as our Autobond Automation Solutions will be the multi-purpose Triad Wedge Welding system and the dedicated function Spec Wedge Welder. The roof welding products are a new market for Miller Weldmaster providing outstanding growth for the company and the opportunity to provide quality service for customers installing roofing membrane products. This expanded welding line provides new opportunities for our customers in helping them in their daily production and manufacturing needs.

Sinclair Equipment Company has been a world leader in manufacturing portable, versatile equipment for the industrial textile and roofing industry. Miller Weldmaster would like to thank Frank and Anita Sinclair for the quality foundation they’ve built and the outstanding service to the industry they have provided. The entire Miller Weldmaster family would like to wish them the best as they move into retirement. With the establishment of a West Coast office, the experienced personnel of Sinclair Equipment continue to provide the customer experience, which has succeeded to build the brand name.

Posted August 12, 2014

Source: Miller Weldmaster

Indonesia Will Impose Filament Anti Dumping Duty

JAKARTA, Indonesia — August 8, 2014 — The Indonesian government will continue focus to reduce dependence on imported of raw materials. Some Indonesian newspapers reported that the ministers under the coordination of the Ministry of Economy are conducting various efforts to address the trade deficit, which the surges of imported products are also potentially hit the national industry.

In early July, the Minister of Trade, Muhammad Lutfi said that he saw some high import products growth. “For that, now we’re together to see how the import of raw materials can be substituted with local products,” said Lutfi.

In the end of July, after the Dialogue Forum with West Java Textile, Garment and Footwear Industry, Minister of Industry, MS Hidayat said that at present nearly 50% of the capital goods and raw materials in the country are imported. And ideally, it needs must be met domestically. “My focus is to strengthen the integration of the industry, until they could reduce imports,” said Hidayat.

The Minister of Industry has also promised to strengthen the upstream of the textile industry to support the development on the downstream sector. “Indeed, the upstream and downstream textile sector should be integrated. Could not just focus on downstream, but upstream of textiles industry must also be strengthened,” said Hidayat.

The Minister’s statement signaled his support for the imposition of antidumping filament yarn that is currently being investigated Indonesian Anti Dumping Committee (KADI). Imposition of anti-dumping duty of three types of filament yarn is expected to reduce imports, so that the country can maintain the balance of trade, especially in the manufacturing sector.

In early July, KADI has released the essential fact as a result of the investigation which found the unfair trade practices (dumping) conducted by the exporters from the People’s Republic of China, South Korea, Malaysia, India, Taiwan and Thailand with a dumping margin at 0 to 17.45 percent.

Committee is also found the material losses that caused injury to the applicant company in which is related injury causation (causal link) to the exporter dumping practices.

The Secretary General of the Indonesian Synthetic Fiber Producers Association (APSyFI), Redma Gita Wirawasta explained that the imposition of Anti Dumping is necessary to create fair competition in domestic market. “Some companies who enjoyed the practice of dumping of cheap goods is definitely going to protest, here the role of government is needed to stop the fraudulent trade practices that had been going on” said Redma.

Redma said that importers will make efforts to divert the issue to the government including the committee is hesitant to make a decision. “The issue that domestic manufacturers cannot produce the type of yarn that is imported only reason without foundation, because in fact we are able to produce all types of yarn within the scope of the HS code which has found its dumping margin by the committee” said Redma.

“The technology used is the same throughout the world, know-how are also at the same level, so any kind of special yarn produced outside we could produce” clear Redma. “But if the price should go import prices that have been proven to dumping, we certainly cannot sell, the sale will continue to lose” he said.

Related with the production capacity, Redma explained that the current utilization level of SDY is 63%, DTY 78%, and POY 73%. “There are still a lot of capacity that cannot be operated, the practice of imports at dumping prices is causing our utilization rates continue to fall, because our market share in the domestic market also fell, and it is already in the scope investigation, so the committee is able to infer the existence of a causal link” he said.

Redma adding that all the complaints by downstream industries through the API are already within the scope of the investigation committee is, so there is nothing that can hinder committee is to implement BMAD.

Posted August 11, 2014

Source: Asosiasi Produsen Synthetic Fiber Indonesia/Indonesian Synthetic Fiber Makers Association

Gildan To Build New Facility In Honduras

Branded apparel manufacturer Gildan Activewear Inc., Montreal, has announced plans to build a new manufacturing facility in its Rio Nance complex in Honduras. The company reports that the new facility will help it meet its production capacity needs until its planned facility in Costa Rica goes on-line in fiscal year (FY) 2017. The Rio Nance addition also will help the company meet its sales growth target for higher-end products, planned for FY 2016, and optimize production efficiencies at its other textile plants.

Gildan expects the Rio Nance addition and the planned Costa Rica plant will increase the company’s overall production capacity by 40 percent compared with the capacity exit rate at the end of FY 2014.

August 5, 2014