LONDON — June 25th, 2013 — Bordeaux Digital Printink, a leading innovator of a wide range of inks

and coatings for a variety of demanding inkjet applications, printing technologies and techniques,

today announced that it will launch its Latex based inks at the FESPA 2013 conference, June 25 –

29, in London, UK, at the Excel London Exhibition Center, stands D12S/E10S. The new water

based inks extend Bordeaux’s comprehensive range of inks and solutions further and raise the bar

for environmentally friendly printing.

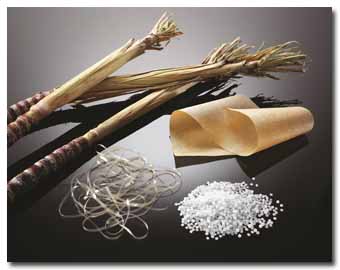

Bordeaux will highlight the new EDEN TX™ Latex based ink for textiles, a unique water based

ink for digital printing on a very wide variety of natural, synthetic and blended fabrics without

pre-treatment, multiple printing devices or several types of ink. This odorless ink offers

extremely rich and high density colors, excellent color vibrancy and soft feeling fabrics, making

it an excellent choice for the demanding environments of garment and apparel, decorative and

industrial textile printing applications. Bordeaux’s EDEN TX currently supports Epson®

DX-4™/DX-5™/DX-6™/DX-7™ printheads, as well as industrial printheads such as Ricoh® Gen4. Available

colors are C, M, Y, K, Lc, and Lm.

Latex printing will be visible on three printers in the Bordeaux stand and in Bordeaux’s

partners’ stands at FESPA 2013, two dedicated for textile printing on cotton and polyester and

another demonstration of a Latex converted solvent Mutoh printer printing with Bordeaux’s EDEN LX™

Latex-based ink. Designed for simple and seamless conversion of solvent based printers equipped

with Epson DX printheads, EDEN LX demonstrates superb performance comparable to eco-solvent inks,

on a wide array of substrates including most solvent and water designated substrates.

“At this year’s FESPA we are demonstrating the versatility and exceptional quality and cost

effectiveness of our environmentally friendly solutions. Our revolutionary Latex based ink series

is odor free, offers excellent durability, superior adhesion, high light fastness and outstanding

elongation properties, making it an excellent alternative to solvent ink for indoor and

outdoor applications,” said Moshe Zach, CEO and founder of Bordeaux Digital Printink. “All this,

while providing 30% to 50% lower ink consumption compared to OEM Eco solvent ink.”

“Bordeaux’s new Latex based ink for textiles builds on our track record of innovative

industry first solutions and enables more efficient digital textile printing,” added Zach. “Best of

all, EDEN TX ink has the ability to precisely match colors even on garment fabrics made up of a

blend of two or more fiber types and produce garments with a soft feel, excellent wash fastness and

light fastness. It is a true breakthrough in the digital textile printing field, ideal for fast and

hassle free short run garment and apparel, decorative or industrial textile printing applications.”

Bordeaux’s water-based ink demonstrations include the first showing of its EDEN SD™ Direct

Sublimation ink. This ink produces washable and color-fast images on Polyester fabrics which can be

used for flags & banners, sports apparel, indoor furnishings, fashion items, tents and more.

Bordeaux will be showcasing its recently announced Eco solvent ink for Epson Surecolor® S

series printers. Mix & Match with Epson UltraChrome GS2 in, this eco-friendly ink is available

in 1L bags for Smart bulk ink delivery systems, provided by InkOnDemand.com, a Bordeaux partner

company.

Environmentally friendly printing will be visible in the UV LED area of the stand, where

Bordeaux will demonstrate its UV LED flexible ink printing on rigid substrates. Bordeaux’s UV

and UV LED ink series cover a very wide range of rigid, flexible and super flexible solutions for

all types of indoor and outdoor applications.

As a key supplier of cost effective solutions to the wide format digital printing industry,

Bordeaux is exhibiting its complementary UV based primers for pre-print to enhance adhesion on

challenging rigid surfaces such as plastic and glass as well as innovative encoder solutions,

advanced bulk solutions and a wide range of coatings for post printing. Bordeaux’s Clear

water based laminates for post-print improve durability and enhance image of outdoor signage and

fleet graphics. The complementary UV coatings for wide format provide additional features

depending on the application such as gloss, matte or anti-slip characteristics.

Visit Bordeaux at FESPA London, the largest focused event for the wide format print industry,

on stands D12S/E10S at the ExCel London Exhibition Centre during June 25 – 29 2013.

Posted on July 2, 2013

Source: Bordeaux Digital Printink