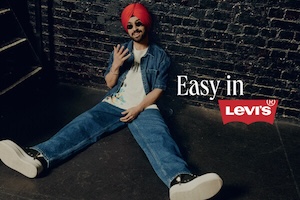

MUMBAI, India— March 28, 2025 — The Levi’s® brand continues to push the boundaries of style and culture with its latest campaign, ‘Easy in Levi’s®’. Featuring Global Brand Ambassador, music icon and fashion trailblazer, Diljit Dosanjh, the campaign brings relaxed and loose fits to the forefront, redefining effortless style with confidence and ease.

MUMBAI, India— March 28, 2025 — The Levi’s® brand continues to push the boundaries of style and culture with its latest campaign, ‘Easy in Levi’s®’. Featuring Global Brand Ambassador, music icon and fashion trailblazer, Diljit Dosanjh, the campaign brings relaxed and loose fits to the forefront, redefining effortless style with confidence and ease.

CULTURE MEETS STYLE

This association isn’t just about style — it’s a cultural moment. Few stars today shape trends like Dosanjh. From sold-out world tours to turning heads in film and fashion, his influence transcends borders. This partnership reflects the brand’s ongoing commitment to blending denim heritage with contemporary style in India.

FITS THAT REDEFINE COMFORT AND CONFIDENCE

Denim trends are evolving, and relaxed & loose silhouettes are taking centre stage. The ‘Easy in Levi’s’ campaign introduces a range of new relaxed and loose fits that deliver a fresh take on comfort and self-expression.

A timeless straight-leg fit, the 555™ Relaxed Straight comes with just the right amount of room for effortless, everyday wear. With a ’90s inspired feel, the 568™ Loose Straight is relaxed with a straight leg, that delivers easy cool vibes. The 578™ Baggy, the boldest of the bunch, features an oversized, slouchy fit with stacked ankles that revive unapologetic ’90s streetwear aesthetics.

DILJIT DOSANJH IN HIS ELEMENT

The campaign unfolds through a series of dynamic montage films that capture Dosanjh in his comfort zone — at soundcheck, effortlessly moving through his world in Levi’s Loose Fits. His style is unfiltered, authentic, relaxed and Easy, perfectly embodying the campaign’s message: Loose Fits aren’t just about what one wears, they’re about how one feels. These jeans are designed to let one move easy, chill easy, and live easy.

“With ‘Easy in Levi’s’, we’re tapping into the growing demand for relaxed and loose silhouettes that marry comfort with style,” said Amisha Jain, managing director and senior vice presidenet, South Asia, Middle East and Africa at Levi Strauss & Co. “Diljit Dosanjh brings this vision to life, proving that when you feel good in what you wear, effortless style follows.”

Crafted for movement and versatility, Levi’s Loose Fits deliver a fresh approach to casual dressing. Whether one’s drawn to the clean-cut vibe of the 555 Relaxed Straight, the carefree energy of the 568 Loose Straight, or the bold attitude of the 578 Baggy, these fits are designed to be lived in and styled in one’s own way.

Levi’s® Loose Fits are available now across Levi’s® stores in India and online at www.levi.in

Posted: March 31, 2025

Source: Levi Strauss & Co.