The 53rd Dornbirn Man-made Fibers Congress (MFC) will be held in Dornbirn, Austria, Sept. 10-12, 2014. The congress is without any doubt the most important event for the global man-made fibers (MMF) community. It is organized by the Austrian Man-made Fibers Institute and supported by the Brussels-based European Man-Made Fibers Association (CIRFS).

Most Important Fibers

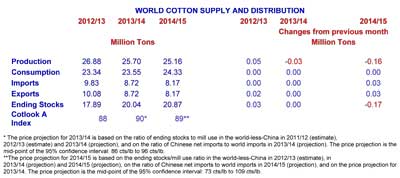

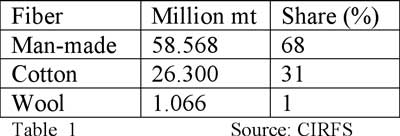

Man-made fibers are by far the most important global fiber consumption sector. Up to the 1990s, the ratio of natural versus man-made fibers was even at 50:50. In the last 15 years, the ratio has changed completely, mostly due to the increasing demand for industrial textile applications and nonwovens. At the moment, the ration is some 68 percent for MMF, and 32 percent for natural fibers. In the year 2012, world fiber production was 85.9 million metric tons (mt). The fiber breakdown and the share of each fiber material speak for themselves:

Is There A Future?

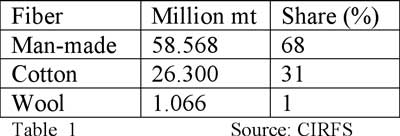

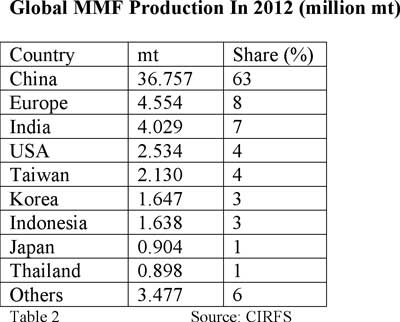

The 53rd Dornbirn-MFC has a very ambitious motto: “Communicating the Future of Man-made Fibers.” This motto is very appropriate if one looks at the situation of the global MMF production sites: During the 1950s up to the mid-1990s, Europe and the United States dominated the man-made fibers market. With the rise of China, this situation has changed completely. The table shows where man-made fibers were produced in 2012:

Broad Spectrum Of The Industry

Dornbirn-MFC organizers say that all the presentations are under the guideline “Innovation, Efficiency and Competitiveness.” As ever, Dornbirn is well-known and appreciated by the broad (sometimes even too wide) spectrum of papers in three different sessions. Some 100 lectures will be given by experts — representatives from the man-made fibers industry, the processing chain and academic research. All of them will use the Dornbirn communication platform for an intensive exchange of ideas. And this platform is very much needed: The organizers mention that “The global challenges of the developments in the financial sector and economies show that along with innovation (cost) efficiency and competitiveness become the decisive key factors for success of the European fiber industry.”

Opening Session

As in every year, the traditional plenary session on the opening day will start with presentations from Austria-based Lenzing AG’s Friedrich Weninger for the Austrian Man-made Fibers Institute and Frédéric Van Houte of CIRFS, and the awarding of the Paul Schlack Prize for outstanding research achievement. These presentations will be followed by a lecture by Oliver Börsch of Germany-based Bionic Strategy, titled “The Re-enchantment of the World – Survival Strategies with Brands as Modern Storytellers in an Engineered World.”

After a short break, Pierre Wiertz of the Brussels-based European Association Serving the Nonwovens and Related Industries (EDANA) will speak about new developments in nonwovens; and Peter Askew of the Organisation for Economic Co-operation and Development (OECD) will give a lecture on the standardization of antimicrobial testing methods. This lecture should be very interesting and is needed because all over the world, testing methods and standards for all kinds of testing often produce confusion more than they provide a helpful guideline.

Of course, every event is a costly matter. The organizers underline the fact that they enjoy a strong commitment and support by the main sponsors from the industry, and are writing that “due to the active involvement in an enlarged base the continuous expansion of the congress can be guaranteed in turbulent times as well.”

Key Factors For Success

Following are the main themes:

- global strategies in a changing environment;

- fiber and filament innovations;

- nonwovens/filtration;

- automotive; and

- key technologies.

The congress’s main theme, “Global Strategies in a Changing Environment,” will treat some of the decisive key success factors. The European Commission will present a paper on the “horizon of experience 2020,” which will focus on innovations and sustainable resources. This paper will be followed by Fenwis GmbH’s report about future textile and MMF markets and developments.

Invista will report on its market research results on consumer trends in textiles. Italy-based Radici Partecipazione S.p.A. will report on “sustainability as a source for market opportunities meeting the challenges of an integrated production.” The well-known German research institute and university RWTH Aachen will close with an industry report, focusing on textile industry workers.

Key Technologies

One of the most important factors for every successful industry is key technologies. This now enlarged section will report on recent findings in the areas of finishing, coating, machinery for spinning/extrusion and joint academic research and industry developments.

Today, quality is an important prerequisite for success. The enhancement in quality is another topic of the congress. Guidelines for this section are global strategies for a change, market specials, new business models and fiber/filament innovations referring to oil- and bio-based fiber raw materials, carbon fibers and functionalities.

The ever-increasing importance of nonwovens is reflected in a section that will have presentations about nonwovens and filtration. Another will cover automotive applications as well as transport products in trains, ships and airplanes.

The Place To Be

The Dornbirn-MFC is an event not to be missed not only for people in the man-made fibers industry but also for professionals who want to know more about the future of nonwovens and the European textile industry. And, last but not least, as at every important gathering of the global textile industry, networking is the key word. More information can be obtained at dornbirn-mfc.com.

April 29, 2014