SPRING, TX — December 22, 2025 — ExxonMobil, one of the largest publicly traded international energy companies, uses technology and innovation to help meet the world’s growing energy needs.

SPRING, TX — December 22, 2025 — ExxonMobil, one of the largest publicly traded international energy companies, uses technology and innovation to help meet the world’s growing energy needs.

The company recently launched its new ExxonMobil Signature Polymers portfolio brand, which focuses on delivering best-in-class service and partnerships within the polymers industry. ExxonMobil Signature Polymers unifies ExxonMobil’s polyolefin products under a single brand, simplifying portfolio navigation and promoting enhanced collaboration across the value chain.

Challenge

Over the past few years, the successful use of recycled polypropylene (rPP) content in non-critical auto parts has helped drive automotive original equipment manufacturers (OEMs) to turn their attention to high-performance functional parts.

Over the past few years, the successful use of recycled polypropylene (rPP) content in non-critical auto parts has helped drive automotive original equipment manufacturers (OEMs) to turn their attention to high-performance functional parts.

OEMs have interest in rPP compounds that can meet application requirements for impact resistance at various temperatures and stiffness benchmarks. Those compounds must also be designed for fast injection molding cycle times which can help address cost concerns.

Additionally, aiming to make the automotive sector circular and maximize the efficient use of resources to protect the environment, the European Commission proposed a new regulation on end-of-life vehicles (ELV) in 2023. The new rules include circular design of vehicles to facilitate removal of materials, parts and components for reuse/recycling, and mandate the use of recycled plastics in automotive applications.1

This ask seems reasonable, but the reality is that this is not easily achieved: rPP content, even when originating from ELV waste, typically struggles to meet such demanding automotive OEM specifications.

Solution

Milliken & Company and ExxonMobil have a long history of working together. As a leading supplier of transformative chemical solutions that deliver essential performance, Milliken routinely helps brands and converters balance and enhance the properties and processability of mechanically recycled polypropylene content. ExxonMobil manages a portfolio of performance products that can provide the building blocks to help meet growing global demand for essential products.

Critical automotive OEM parts, such as wheel arch, and front fascia deflectors , must meet flexural modulus (stiffness), tensile strength, and impact strength specifications, so formulations that incorporate rPP content would have to meet these physical property requirements without compromising final performance or negatively impacting the injection-molding process.

Each company brought a unique skill set to help address the challenge. The companies developed trial formulations built around Milliken’s DeltaMax® performance modifiers and ExxonMobil’s Exact™ polyolefin elastomers (POE).

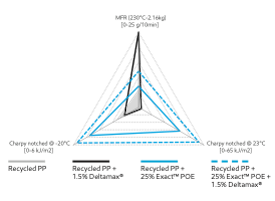

The technical team conducted several compounding trials using up to 25% Exact POE enhanced with DeltaMax® and post-consumer rPP content containing approximately 15% polyethylene.

These compounds were molded into dumbbell-shaped samples, which were then tested for flexural modulus, tensile strength, impact strength at 23 °C and at –20 °C, and for melt flow rate (MFR).

Results

The test results showed a Notched Charpy impact of 50 kJ/m2 at 23°C and 4 kJ/m2 at -20°C could be achieved with a flexural modulus of approximately 900 MPa and a tensile strength significantly above the target from various OEMs — passing the first hurdle of balancing mechanical performance. The MFR was improved more than two-fold over the initial rPP content compound, which has the potential to help reduce part processing costs. This can be achieved by decreasing operating temperatures and lowering cycle time, which can lead to lower energy consumption in the manufacturing process and a lower carbon footprint of the final part.

These results come from the innovative formulation enabled by Milliken and ExxonMobil’s collaboration:

These results come from the innovative formulation enabled by Milliken and ExxonMobil’s collaboration:

- The rubber-like behavior of Exact™ POE can help improve impact strength and limit drops in stiffness compared to other impact modifiers.

- DeltaMax® performance modifiers can help improve flow rate and help boost impact further over recycled PP with Exact POE through compatibilization of the matrix-rubber interface, thus helping to facilitate particle dispersion and small particle size.

Following the successful initial trial, ExxonMobil and Milliken collaborated with Ravago, one of the leading compounders and recyclers, to evaluate a new formulation designed to meet the evolving requirements of the automotive industry.

Following the successful initial trial, ExxonMobil and Milliken collaborated with Ravago, one of the leading compounders and recyclers, to evaluate a new formulation designed to meet the evolving requirements of the automotive industry.

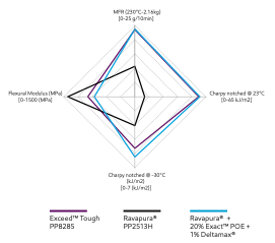

The trial featured a blend of 20% Exact POE, 1% DeltaMax® performance modifier, and Ravapura®, a compound incorporating 25% certified post-consumer recycled (PCR) content — including 6.25% ELV material — in compliance with the new EU regulations.

Benchmarked Ravapura® grade meets the new ELV content thresholds and is suited for specific applications/parts in cars. The enhanced formulation demonstrated significant performance gains:

- Melt Flow Rate (MFR): Improved by 200%

- Charpy Impact at Room Temperature: Increased by 660%

- Charpy Impact at -30°C: Increased by 200%

Although the addition of Exact POE slightly reduces flexural modulus, it substantially enhances impact resistance — bringing performance levels close to those of virgin materials like Exceed™ Tough PP8285E1. Trial results demonstrated that the formulation delivers comparable flow and impact performance to Exceed Tough PP8285E1, under both room temperature and extreme cold conditions (-30°C). This positions the solution as a strong candidate for OEMs and compounders seeking to balance regulatory compliance, sustainability, and mechanical performance in automotive applications.

“We’re excited to see the compound that incorporates rPP achieves similar (and even exceeds) performance as virgin materials,“ said J Dow, Global Market Development Manager for Polyproplylene, Vistamaxx™ and Exact™ at ExxonMobil. “This well demonstrated the value and power of collaboration that we can unleash possibilities by working together to help our customers meet stringent regulations.”

“The creation of viable compounds that incorporate rPP content is a major win, and we’re proud to play a role in solving this challenge together with our collaborators at ExxonMobil,” added Dr. Philippe Scheerlinck, Senior Market Development Manager for Milliken’s Chemical Business.

Data from tests performed by or on behalf of ExxonMobil

Posted: December 26, 2025

Source: ExxonMobil Signature Polymers