An effective odor control solution for textile products needs to address the multifaceted sources of odor.

By Ryan Scott

Human body odor, while often invisible, poses a significant and persistent challenge in the world of textiles. It’s more than just an unpleasant smell; it represents a key consumer pain point that can dramatically impact brand perception and product longevity. As interest in performance textiles and sustainable practices grows, so does the demand for truly effective and lasting odor control. Yet, achieving this goal is far from simple. It requires a deep scientific understanding of human body odor as a multifaceted phenomenon, moving well beyond simplistic assumptions and single-solution approaches. As the textile industry continues to innovate, mastering odor control hinges on embracing the chemistry at play and adopting comprehensive, scientifically rigorous evaluation methods.

A Complex Chemical Symphony

Contrary to common belief, human body odor cannot be attributed to a single source or compound. Instead, it is a complex and dynamic mixture of volatile organic compounds (VOCs). This intricate chemical symphony is influenced by a confluence of factors, including an individual’s biology, their environment, the specific chemistry of the textile substrate and the activity of skin-resident microbes. The AATCC 2017 White Paper on Odor Evaluation Techniques for Textiles highlighted this complexity, presenting real-world case studies where detailed odor intensity and character profiling consistently revealed that garments carry a broad array of olfactory signatures. Trained sensory assessors in these studies identified a diverse range of descriptors, including animalic, earthy, floral and chemical notes, confirming that body odor originates from multiple families of odorants, not just a single compound.

Among the most common and impactful odorants found in textiles are distinct chemical entities, each presenting unique challenges for odor control technologies:

- Isovaleric Acid (C5H10O2): This short-chain branched fatty acid is characterized by a pungent, cheesy odor. It is primarily produced through the microbial metabolism of amino acids, such as leucine. Being moderately hydrophobic, isovaleric acid tends to bind readily to synthetic fibers, making its removal a persistent challenge.

- Acetic Acid (CH3COOH): A small, polar carboxylic acid, acetic acid is often a byproduct of sweat fermentation. Its sharp, vinegar-like smell is distinct from isovaleric acid. Due to its higher solubility in water and volatility, it behaves differently in textile substrates, requiring different neutralization strategies.

- Ammonia (NH3): This basic, highly volatile gas is formed through the degradation of urea, a component of sweat. Known for its sharp, irritating smell, ammonia can rapidly escape fabrics. However, its alkaline nature presents a different set of challenges for odor neutralization technologies compared to acidic compounds.

- Nonenal (C9H16O): An unsaturated aldehyde, nonenal is frequently associated with the “cardboard” or “greasy” odor often linked to aging body odor. This molecule is highly lipophilic, meaning it strongly binds to fibers, particularly polyester, and is notoriously difficult to remove, demanding specific and robust strategies for effective neutralization.

The critical takeaway here is that each of these molecules represents a distinct chemical class — acid, base, aldehyde — and interacts uniquely within textile matrices. An odor control solution designed to capture or neutralize an acid may not effectively interact with a base like ammonia or a nonpolar aldehyde such as nonenal. Therefore, a truly effective solution must possess a multifaceted mechanism capable of addressing this broad chemical diversity.

Why Single-Odorant Testing Methods Fall Short

Despite the inherent chemical diversity of human body odor, a prevailing practice in the textile industry has been to validate many odor control technologies using only a single odorant, most commonly isovaleric acid. While isovaleric acid serves as a useful benchmark for certain aspects of foot and sweat odor, relying solely on it for performance validation is fundamentally insufficient to represent the full complexity of body malodor. This narrow testing can lead to misleading claims, as products appearing effective against isovaleric acid may utterly fail to address other critical odorants like nonenal or ammonia, which significantly impact perceived freshness, particularly in active wear or among aging populations.

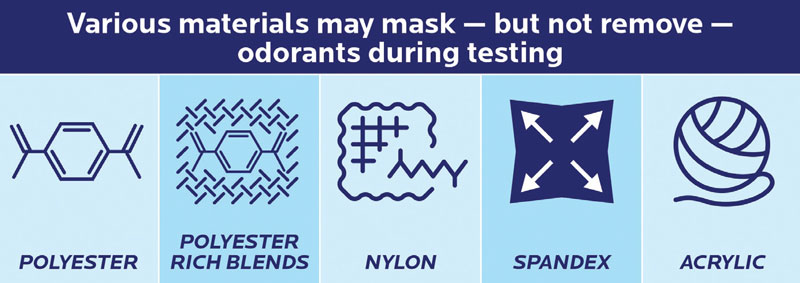

Furthermore, the choice of fabric composition plays a critical, yet often underestimated, role in odor performance and can exacerbate the limitations of single-odorant testing. Spandex, or elastane, is a prevalent fiber used in performance apparel due to its stretch and recovery properties. However, its inclusion significantly alters odor behavior. Spandex is known to have a greater affinity for isovaleric acid, nonenal, and acetic acid than common synthetics like polyester or nylon. This affinity allows spandex to delay the release of odorants, which can inadvertently inflate odor reduction results in controlled laboratory settings. Crucially, this retention does not equate to true odor elimination; in real-life wear, trapped odors in spandex may be rereleased over time, especially when exposed to body heat and motion. Consequently, testing with spandex-containing fabrics, particularly when combined with isovaleric acid-only evaluation, risks overstating a product’s true performance and masking the technology’s limitations in broader, real-world scenarios.

To genuinely understand and enhance textile odor control, the industry must evolve beyond these simplistic test models. A multi-odorant, chemically diverse evaluation approach is imperative to reflect the true nature of human malodor.

Establishing The Gold Standard: ISO 17299

Recognizing the limitations of single-odorant testing and the complex nature of body odor, the global textile industry has increasingly turned to the ISO 17299 standard as the benchmark for assessing deodorant properties in textiles. This international standard is specifically designed for comprehensive, multi-odorant and chemically diverse evaluation, ensuring a more accurate representation of real-world performance.

The ISO 17299 standard is com-posed of several parts, each addressing specific aspects of odor assessment:

- ISO 17299-1: General Principle — This foundational part outlines the overarching methodology and principles for evaluating deodorant properties, emphasizing a holistic approach to address diverse odorants.

- ISO 17299-2: Detector Tube Method — This section details the procedure for evaluating deodorant performance using detector tubes, primarily for assessing gaseous odorants such as ammonia and acetic acid.

- ISO 17299-3: Gas Chromatography Method — This part specifies the use of gas chromatography for the precise quantification of odor reduction for more complex VOCs like isovaleric acid and nonenal. This instrumental analysis provides objective and repeatable data on a technology’s efficacy against these key odorants.

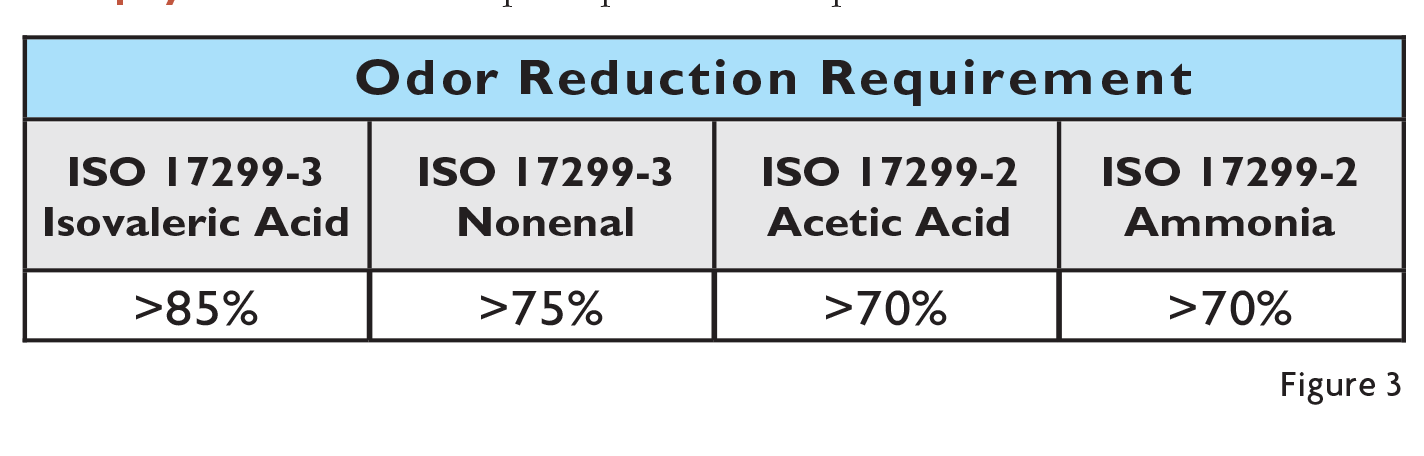

To achieve ISO 17299 certification, textile products must meet minimum reduction rates for each of the four identified key odorants — isovaleric acid, nonenal, acetic acid, and ammonia (See Figure 3). These thresholds were rigorously established based on extensive sensory testing and validated through the instrumental analysis methods outlined in the standard, ensuring that the defined reduction levels correspond to a noticeable and effective improvement in perceived freshness.

This rigorous, multi-faceted standard serves as the critical baseline for any credible odor control claim, pushing the industry towards more robust and reliable solutions that truly address the spectrum of human body odor.

Next-Generation Odor Control Technologies

The growing understanding of odor complexity, coupled with the rising consumer demand for high-performing and sustainable textiles, has spurred innovation in odor control technologies. Many traditional solutions, particularly those relying on metal-based chemistries or biocides, or those with limited wash durability, have proven inadequate in meeting these evolving demands, especially after repeated home laundering. This landscape has driven the development of advanced solutions that are designed to effectively man-age the full spectrum of malodors while aligning with modern safety and environmental standards.

A compelling example of this next-generation approach is Freshology™, developed by Microban International Ltd., Huntersville, N.C. This technology represents a nature-inspired, heavy-metal-free and non-biocidal solution specifically engineered to neutralize the broad spectrum of impactful body malodors, including isovaleric acid, acetic acid, ammonia and nonenal.

Unique Mechanism

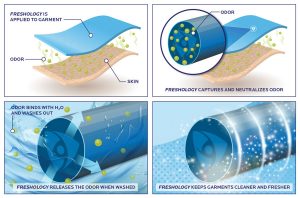

The science behind Freshology centers on its unique mechanism of action, which involves a proprietary blend of polymers and natural components (See Figure 4). This blend is designed to capture and neutralize VOCs through a combination of physical and chemical interactions. The captured odorants are then later released and effectively washed away during laundering. This cyclical mechanism is key to the technology’s ability to maintain lasting freshness across repeated uses and launderings, making it a robust option for performance textiles.

In terms of application, technologies like Freshology are often designed for seamless integration into existing textile production lines. For instance, it can be applied through standard pad finishing processes without requiring additional steps, and it typically demonstrates compatibility with common fiber types such as polyester, nylon, and various blends, as well as a flexible pH range and curing temperatures.

In practice, a technology built on these principles has undergone rigorous testing against all four primary odorants identified in the ISO 17299 standard. Such technologies are observed to consistently meet or exceed the standard’s reduction thresholds across a wide range of fabric types, including synthetics that typically present a challenge for odor management. Furthermore, their performance is designed to exhibit observed durability and retain effectiveness even after numerous home launderings, indicating their potential for providing long-term odor control in demanding textile applications.

Beyond performance, sustainability and safety are increasingly vital considerations. Advanced odor control technologies often feature environmental profiles that are heavy metal-free and non-biocidal, aligning with evolving regulatory landscapes and consumer preferences. Such innovations may also pursue relevant textile certifications like Oeko-Tex® Eco Passport and Bluesign® Approval, signaling adherence to high standards for environmental health and safety. The development and patenting of unique odor capture systems under-scores the commitment to scientific advancement within this field.

Elevating Textile Freshness With Scientific Rigor

The complexities of human body odor demand a sophisticated, multi-odorant approach to effective odor control in textiles. Single-odorant testing methods are insufficient to capture the full picture, potentially leading to products that underperform in real-world conditions. The ISO 17299 standard serves as a critical global benchmark, offering a comprehensive and scientifically rigorous framework for evaluating a technology’s ability to neutralize the diverse chemical spectrum of body malodor.

Innovative, science-backed solutions, such as Freshology, are crucial for brands aiming to deliver on the promise of long-lasting freshness and superior performance. By embracing a deep scientific under-standing of odor chemistry and adopting thorough testing methodologies, the textile industry can advance beyond mere masking agents to create textiles that truly neutralize odors across the full spectrum, ensuring they remain fresher longer and meet the increasingly high expectations of today’s discerning consumers.

Editor’s Note: Ryan Scott is a senior product development chemist at Microban International Ltd., Huntersville, N.C.

2025 Quarterly Issue III