Albstadt, Germany — July 3, 2025 — On July 8, 2025, Mayer & Cie will celebrate its 120th anniversary. The company, now in its fourth generation of family ownership, specializes in the production and sales of circular knitting and braiding machines. Almost all its products are exported, and the green MCT logo on the machines is recognized by knitters around the world as a symbol of precision, durability, and reliability.

Albstadt, Germany — July 3, 2025 — On July 8, 2025, Mayer & Cie will celebrate its 120th anniversary. The company, now in its fourth generation of family ownership, specializes in the production and sales of circular knitting and braiding machines. Almost all its products are exported, and the green MCT logo on the machines is recognized by knitters around the world as a symbol of precision, durability, and reliability.

Time and again, Mayer & Cie.’s inventive developers have delivered key technical milestones. Today, digital solutions are increasingly important: a circular knitting machine is expected not only to deliver production data to the cloud but also to be remotely maintained. In the field of braiding machines, Mayer & Cie. now offers 48-carrier models, enabling the production of even larger hose diameters.

“We are truly proud to be celebrating this anniversary,” says Benjamin Mayer, Managing Partner of Mayer & Cie. “120 years of a family business is far from a given: statistics show that only about 12 percent of family-owned companies make it past three generations – and we are already in our fourth,” he adds with a smile.

“This proves that we’ve consistently understood market demands and met them with technological innovation.” Mayer & Cie. has frequently set industry standards, such as the introduction of electronic pattern control or the pioneering Relanit technology.

Challenging times for textile machinery manufacturing

Despite the joy of the anniversary, current global conditions cast a shadow over the festive year. The order situation in Germany’s textile machinery industry remains difficult, and a turnaround is not yet in sight. “We’ve lived through many crises since 1905,” says Mayer. “But the one we’re facing today is by far the most challenging.”

As a result, the company expects significantly lower volumes through 2026 than at full capacity. It has cut running costs significantly, and the workforce has agreed to forego bonuses. Providing a reliable outlook remains difficult: “As a company, we are well positioned, with answers to market needs and modern production processes. This has also been confirmed by third parties. But how the global economy will develop is impossible to predict.”

Latest milestone: connecting circular knitting machines to the internet

A major recent development is a new machine control system that makes Mayer & Cie.’s circular knitting machines “IoT-ready.” This means they are technically equipped to connect with and be integrated into the Internet of Things. The new control system allows Mayer & Cie. customers around the world to access knitlink, a digital platform offering various apps for circular knitting machines.

A new visual monitoring tool has also been introduced – a practical solution, given that errors in fabric can quickly become costly: a circular knitting machine produces around 2.5 meters of fabric per minute.

Another focus lies on upgrade kits. These allow customers to keep their machine park up to date without having to invest in entirely new machines. “This supports machine longevity and sustainability,” explains Benjamin Mayer. “It also increases investment security for our customers.”

Braiding machine with 48 carriers

Just before Christmas 2024, Mayer & Cie. delivered its first braiding machine equipped with 48 carriers (bobbin holders). The second model with this configuration is currently under development. Customers benefit from a larger inner hose diameter, reduced setup times, and the same high bobbin capacity – whether processing yarn or wire.

Mayer & Cie. braiding machines are used to manufacture reinforcement braids, such as those found in high-pressure hoses used in industries like manufacturing and mining.

Since 2019, braiding machine production has been located at the company’s headquarters in Albstadt. One reason for relocating production – which had been handled by a U.S. subsidiary between 1977 and 2019 – was to improve research and development. “That strategy has paid off,” says Benjamin Mayer. “Our innovations now offer our customers greater productivity.”

Technological milestones

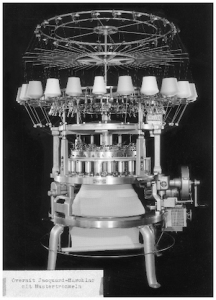

Innovation and technical advancement have long defined Mayer & Cie. Historically, milestones were purely mechanical: in 1938, the company launched its first proprietary circular knitting machine, based on its own patents. Prior to that, it had focused on manufacturing warp knitting machines, known as round frames. But as circular knitting machines proved faster and more efficient, production of warp knitting machines ceased entirely in 1958.

In the mid-1960s, Mayer & Cie. released a machine that became known as “every knitter’s favorite”: the OVJA 36, with innovative pattern control and suitable for especially fine fabrics. Customers were willing to wait up to three years for delivery, and order confirmations became objects of speculation. With around 7,000 units sold, it made the company world-famous in the industry.

In the late 1980s, Mayer & Cie.’s Relanit series continued this success story. With a new knitting technique, these machines delivered excellent fabric quality even when using substandard yarn.

Another technological revolution was the introduction of electronic pattern control, presented by Mayer & Cie. at a leading industry trade show in the 1970s. What used to take a full day of manual work could now be done with the press of a button.

Four generations of Mayer family leadership

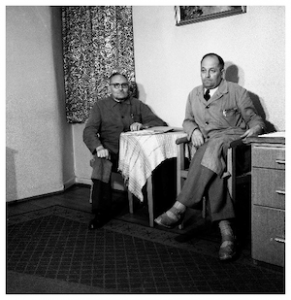

The Mayer & Cie. story is also the story of the people who have led the company. Johannes Mayer, co-founder of the United Mechanical Workshops Mayer & Cie., was a hands-on tinkerer with a passion for detail. He played a major role in developing the company’s first circular knitting machines starting in 1935. When he passed away in 1958, he was remembered as the “first servant of his work.”

His son, Emil Mayer, joined the company as an apprentice in 1921. As an engineer, he later drove the development of proprietary circular knitting machines and built up the company’s international business after World War II. He was posthumously named an honorary citizen of Tailfingen for founding a textile school.

Emil’s son, Peter Mayer, joined the company in 1961 and took over leadership in 1971 alongside his brother Rainer. He further expanded internationalization, was an early advocate of electronics, and shaped the market with the Relanit machine starting in 1987. He retired in 2003.

Rainer Mayer joined Mayer & Cie. in 1972 and co-managed the company from 1973. He focused on diversification, expanded business with IBM, and successfully led the company through insolvency in 2009.

Since Rainer Mayer’s passing in 2015, the fourth generation has taken the helm. Benjamin, Marcus, and Sebastian Mayer now share responsibility for the company’s various business areas.

Posted: July 3, 2025

Source: Mayer & Cie. GmbH & Co. KG