TW Special Report

The extra-long staple Egyptian Giza cotton for years has been the fiber of choice for making premium clothing and home textiles. Recently, Egypt-based spinning specialist Mediterranean Textile Co. (MTC) has been reinventing Giza cotton and teaching this old fiber new tricks to expand its market possibilities, competitiveness, and relevance to emerging market trends.

MTC is to launch a new line of Inherently flame-retardant (FR) spun yarns based on extra-long staple Egyptian Giza cotton blend, which is also known as Giza-Protect®. This new line has been developed to offer customers excellent flame-retardancy and heat resistance with the natural softness and comfort of Egyptian cotton with no deterioration in flame retardancy after repeated washing or normal use over time. These properties make it suitable for multiple applications in protective clothing and industrial workwear.

Most significantly, notes the company the environmental credentials of this line of inherent FR yarns are enhanced through the use of natural fiber such as cotton, which is responsibly grown and processed.

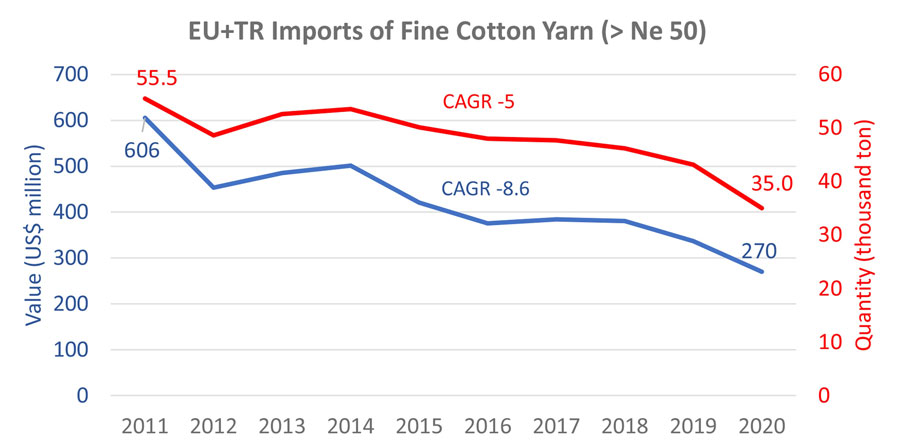

“The global demand for fine cotton yarns has not seen much growth over the past years, and we saw an excellent opportunity to diversify our offerings and introduce Giza cotton to new emerging markets such as FR fabrics for protective clothing,” remarked MTC Managing Director Harald Westphal. “The fineness and strength of Egyptian cotton provides higher durability and extreme comfort that cannot be achieved by any other cotton variety.”

Giza-Protect is the product of an extensive R&D program that was conducted in partnership between MTC and Egypt-based textile research company Intexive. The R&D program was focused on developing a cotton blend yarn that possesses permanent FR functionality and has the ability to self-extinguish when the flame source is removed. This new yarn does not even melt or form droplets, and it is said to be blended with antistatic fiber which provides a double static control mechanism which protects workers against arc flash which has become the newest challenge to protective clothing.

“We have been working on this project for the past 2 years, and now we are ready to launch this new yarn,” said Intexive Managing Partner Dr. Mohamad Midani. “We have done stringent testing of woven fabrics from Giza-Protect yarns at The Textile Industry Research Association (AITEX) in Spain, and the yarn satisfies numerous FR standards around the world for technical fabrics for protective clothing, including EN 11612, EN 11611, EN 1149 and EN 64182.”

“Giza-Protect is an excellent example of the endless possibilities of Egyptian Giza Cotton, it’s a live demonstration on how this amazing fiber can continuously adapt to new market needs and trends,” Westphal said. “We see it as an opportunity to expand the reach of Egyptian cotton in new avenues that were never explored in the past!”

This new yarn is one example of the future range of MTC yarns, which is put forward to demonstrate the versatility of Egyptian Giza cotton. The yarn will be available for commercial supply starting January 1, 2022, and it is said to be available in regular ring spun, compact and core spun yarn, in various blends of antistatic fiber ratio, in wide range of counts Ne 5 to Ne 100.

November 2021