TW Special Report

TW Special Report

Odor control claims for antimicrobial textile solutions have always been based on the assumption that reducing bacterial populations will subsequently eliminate odor, however, until recently it has been near impossible to quantify the efficacy of odor elimination and the benefit to end-users. The Research Triangle Park, N.C.-based American Association of Textile Chemists and Colorists (AATCC) has now developed an objective method that can articulate the efficacy of odor control technologies in as little as 48 hours. Kate Hawley, senior microbiologist, and Dr. Glenner Richards, director of Microbiology and Analytical Chemistry, both from Microban International — an early adopter of this test method — explain how this industry-wide test can prove that odor abatement strategies offer valuable and quantifiable functional benefits for the user.

The demand for odor control and capture technologies in textiles is growing steadily with more key players engineering these strategies into performance finishes. For many consumers, unpleasant odors are almost synonymous with perceived uncleanliness, and increasing public concern for hygiene is driving the market demand for specialized textiles, particularly in medical materials and activewear. Odor control or capture can help to keep unwanted smells at bay, improving consumer satisfaction and increasing the usable lifetime of garments that would otherwise be hampered by excessive washing or persistent smells.

The Economic And Environmental Consequences Of Odor

The malodor that stubbornly remains in textiles even after washing is referred to as “permastink: and is caused by the metabolism of sweat by bacteria on the skin. The problem is most apparent in performance textiles that are made from synthetics, polyester, nylon and elastane blends, and used for dynamic and sweat-inducing activities, where the odorant chemically bonds to the material fibers. To make matters worse, these fabrics often come with recommendations to wash at lower temperatures, which is not sufficient to kill most odor-causing bacteria. As a result, consumers often wash their garments multiple times using harsh cleaning chemicals in an attempt to remove the persistent permastink, increasing both water and electricity usage.

Frequent laundering is not only ineffective at removing ingrained smells, but often reduces the quality of clothing, resulting in premature ripping, fraying or color fading. This causes consumers to render articles unusable earlier than their intended lifetime, adding to the escalating amount of waste that the textile industry produces. In the US alone, 3.2 million tons of textiles were incinerated and 11.3 million tons sent to landfill in 2018,* a large proportion of which is considered ‘nondurable goods’ such as footwear, sheets and towels. Consumers, market leaders and governing bodies are understandably pushing for solutions that can increase the usable lifetime of a garment to reduce this considerable environmental burden.

A Powerful Solution

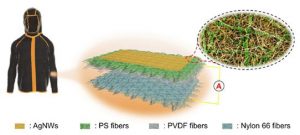

Leading textile manufacturers have adopted a broad spectrum of organic, inorganic and organometallic odor control and capture technologies to help overcome the social, economic and environmental consequences of unwelcome smells on fabric. These odor abatement strategies include antimicrobial formulations that are proven to help fight the growth of microbes — such as bacteria, mold and mildew — on materials, preventing extrinsic discoloration, odors and early product deterioration. Antimicrobial technologies work on the premise that keeping bacterial populations low will diminish the odor generated by bacterial metabolic activity. Alternatively, odor capture technologies form a protective barrier to trap and neutralize body odorants, without interfering with microbial metabolic pathways or growth.

How Do We Measure The Value Of These Technologies?

The textile industry has been missing a concrete and objective method for directly measuring odor reduction and communicating these benefits to users. Previous testing has focused on the impact that antimicrobials can have on bacterial populations, with the inference that these broad-spectrum technologies will reach the problematic, odor-causing bacteria. Therefore, when a technology is shown to reduce the microbial population — some of which will be odor-generating types — it is simply reasoned that the production of odorous compounds will be lessened.

However, this testing does not determine the extent of these capabilities or show the tangible benefits of inhibiting bacterial numbers. Colony counting is also an arduous task that can take researchers many days to complete, and can only give dead/live accounts of microbial viability, without investigating modes or mechanisms of attack. Without fully understanding the power of these technologies for reducing odor, manufacturers may overuse or underestimate the quantity of antimicrobial additives that are required to meet their guidelines, potentially adding to the economic and environmental cost of performance textiles. In addition, enumeration of bacterial populations is only appropriate for antimicrobial technologies, and cannot be applied to odor capture strategies that do not inhibit microbial activity but use an alternative approach such as neutralizing odors that are a consequence of bacterial metabolism. The problem of odor is also multi-faceted and testing methods need to consider not only the growth of microorganisms, but also fabric retention and the types of odorous volatile compounds that cause concerns, to give a definitive description of odor control capabilities. Implementing an industry-wide method that uses a biological system to replicate real-world odor production gives more conclusive answers to the efficacy of all of these technologies.

A Novel Test Method

The AATCC has developed a novel, objective test method (AATCC TM211-2021) to articulate the value of odor control strategies and provide definitive, scientific evidence for odor reduction claims, helping to support regulatory and product registration, as well as communicate benefits to consumers. This highly sensitive test gives real-time and visual depictions of ammonia levels — a pungent and volatile odorous compound that is created when urease catalyzes the hydrolysis of urea in bacterial metabolic pathways — on a colorimetric scale and as a percentage reduction compared to untreated fabric, in under 48 hours. The straightforward method of inoculating the test material in a sealed flask, allowing the bacteria to grow for 18-22 hours, and then collecting the ammonium gas in a Drager gas detector tube for a following eight hours, has been approved by the AATCC and can be adopted by labs worldwide.

Unlike other analytical methods that introduce a synthetically produced odorant, this biological system measures the reduction of an odorant that is microbially generated to represent real-world benefits to the user. Two known ammonium-producing bacteria were used to evaluate this method, gram-positive Staphylococcus saprophyticus and gram-negative Proteus vulgaris, both of which are excellent surrogates for assessing odor development. This technique can be used across the textile industry for quantifying the odor control propensity of both antimicrobial-based technologies and other odor capture techniques.

Development of the method began in 2009, specifically in relation to assessing incontinence products where odor is a major factor of consideration. However, it soon became evident that the technique would be effective for a broad range of products — from clothing to outdoor materials — and an industry-wide spectrum of fabric treatments. The methodology behind the test has also led to some interesting insights, for example, it has shown that antimicrobial technologies significantly reduce odor before bacterial numbers drop, suggesting that the chemistries involved may begin inhibiting metabolic processes before the microbe itself is killed.

An Industry-Wide Advancement

The new method is a significant step that can be applied to manufacturing quality control procedures, as well as textile development programs, to evaluate the concentration of additives needed for sufficient odor reduction help to prevent overuse, and keep costs low. This development could not have come at a better time for the industry, offering an exciting and remote alternative to the traditional in-person odor assessments and wear trials that the COVID-19 pandemic made impossible. The Drager style method also partners well with existing textile test procedures, such as the AATCC TM100 which assesses bactericidal effects, to show the correlation between bacterial reduction and odor control. Manufacturers have a corporate responsibility to be able to quantify the benefits of their technologies with sound scientific research; this sensitive test method demonstrates that odor control adds real value to the end product.

Conclusion

Odor control and capture technologies have long been used to help overcome the environmental and economic cost of premature fabric disposal, as well as improving customer satisfaction. However, measuring these capabilities has proved challenging, without clear answers on how to communicate the benefit of reducing microbial growth on clothing to the everyday consumer. The newly approved AATCC TM211-2021 test can for the first time truly quantify the actual value of odor control technologies, showing that they are meaningful applications and ones that the textiles industry should continue to adopt as consumers seek more sustainable solutions.

To find out more information about AATCC TM211-2021 or any other test method, please visit https://aatcc.org/testing/.

AATCC Committee participation is open to all. For those with comments, suggestions, or want to be part of the innovation AATCC creates, you are welcome to join and make an impact on present and future AATCC test methods!

* Textiles: Material-Specific Data | US EPA. (2021). Retrieved 19 October 2021, from https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/textiles-material-specific-data

November 2021